4

7.3.

Overload protection

The built-in thermal overload trip prevents the pump from being overheated.

The pump must cool down.

Check the following operating conditions:

•

- Is there a sufficient water supply?

•

- Has the filter become clogged?

•

- Has dirt entered the pump housing (Follow the cleaning instructions below)?

•

- Have hoses or jets become clogged?

•

- Has the pump cooled down?

As soon as you have solved the problems, you can start the pump again, pulling the plug out and putting it

again in the socket after a short time (1 min.)

8. Dismounting / mounting the pump

Figure III

1. Follow the safety measures.

Disconnect the pump

!

2. Remove the top shell from the pump cage in accordance with fig. III/1

3. Loosen the pump's retaining bracket as shown in fig.III/2

4. Remove the entire pump with pump housing from the lower shell. (III/3)

5. Unscrew the flow rate regulator from the inflow cover

6. Loosen the 4 screws (III/5).

7. Unclip pump housing (18) from motor housing (III/6).

8. Remove rotor assembly (19) from motor housing. Pay attention to the O-ring (22) in the motor housing (III/7).

9. Clean all parts using clear water and soft sponge.

Mounting:

10. Press the O-ring (22) onto the rim in the motor housing.

11. Push the rotor assembly (19) onto the motor housing (5) with precaution and turn the bearing cap so that the two

holes fit on the pins in the motor housing (5).

12. Make sure the rotor assembly is free and will turn.

13. Check the position of the O-ring (22) in the motor housing (5).

14. Plug the pump housing (18) in the motor housing (5) and tighten the 4 screws uniformly.

15. Re-insert the pump into the pump cage by following the steps in reverse order..

For trouble-free operation, repeat this procedure depending on the degree of fouling and duration of operation.

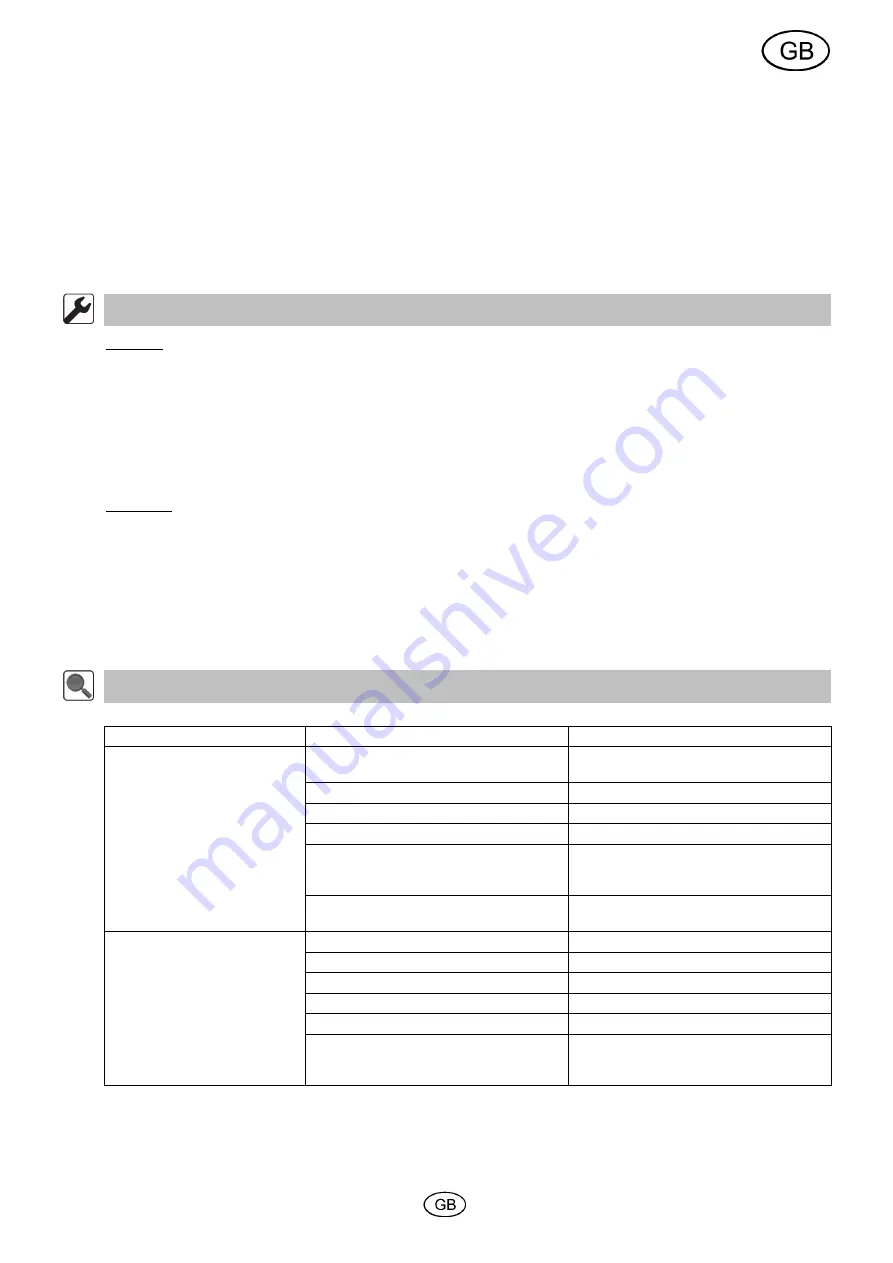

9. Troubleshooting/recommendations

Fault

Possible cause

Remedy

No delivery capacity

Power supply interrupted

Plug in the power plug

Check fuse

Cable is defective

Dispose of pump

Motor block is defective

Dispose of pump

Pump is calcified, rotor has seized

Dismantle pump and descale

Rotor is blocked by sand

Dismantle and clean pump

Change the set up location as specified in

the usage instructions

Pump is taking in air

Pump is too close to the water surface and

is taking in air

find a deeper location

Insufficient pump capacity

Front cover is clogged

Clean front cover

Hose system dirty

Clean hose and/or outflow

Hose is too long

Shorten the hose

Insufficient hose diameter

Use a hose with a larger diameter

Outflow is positioned too high

Reduce required delivery head

Pump is taking in air

Pump is too close to the water surface and

is taking in some air

find a deeper

location

9

Содержание BPF 8000 E

Страница 3: ...1 3 2 I 3 2...

Страница 4: ...II 5 2 1 3 4 6 7 8...

Страница 5: ...III 2 1 3 4 5 6 7...

Страница 6: ...IV...

Страница 47: ...1 T I P 1 1 2 2 3 2 4 2 5 3 6 3 7 3 8 4 9 4 10 5 11 5 12 5 1 8 RCD FI 30 mA 41...

Страница 49: ...3 5 10 m 2 25 mm 32 mm 40mm 6 IV 35 C I I 1 I 2 BPF 8000 E I 2 25 cm 2 m II 40 C 4 7 8 7 1 7 2 43...

Страница 51: ...5 10 vis major a 1 2 3 11 www tip pumpen de 12 PDF service tip pumpen de EU EU 2012 19 EK 45...