3

20180620 Swegon reserves the right to alter specifications.

WISE

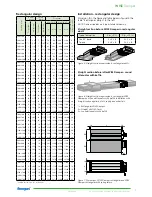

Damper

Rectangular design

Si

ze B

X

H (

m

m

)

Normal

motor

Spring

return

Flow range

To

ler

anc

e Q

*

±

5%

w

ith a

t l

ea

st ±

x l

/s

To

rq

ue

(

Nm

)

W

eig

ht

(

kg

)

To

rq

ue

(

Nm

)

W

eig

ht

(

kg

)

Min. (1 m/s)

Max. (10 m/s)

l/s

m

3

/h

l/s

m

3

/h

200 x 200

5

7.2

5

8.0

34

123

400

1440

4

300 x 200

5

8.4

5

9.2

50

180

600

2160

6

400 x 200

5

9.9

5

10.7

67

242

800

2880

8

500 x 200

5

11.4

5

12.2

84

303

1000

3600

10

600 x 200

5

12.9

5

13.7

100

360

1200

4320

12

700 x 200

5

14.4

5

15.2

117

422

1400

5040

14

800 x 200

5

15.4

5

16.2

133

479

1600

5760

16

1000 x 200

10

18.4

10

19.9

167

602

2000

7200

20

300 x 300

5

10.9

5

11.3

76

274

900

3240

9

400 x 300

5

12.4

5

12.9

102

368

1200

4320

12

500 x 300

5

13.9

5

14.4

127

458

1500

5400

15

600 x 300

5

15.4

5

15.9

152

548

1800

6480

18

700 x 300

10

16.8

10

17.8

178

641

2100

7560

21

800 x 300

10

18.4

10

19.4

203

731

2400

8640

24

1000 x 300

10

21.4

10

22.4

254

915

3000

10800

30

400 x 400

5

14.0

5

14.5

136

490

1600

5760

16

500 x 400

10

16.0

10

18.0

171

616

2000

7200

20

600 x 400

10

17.4

10

18.5

205

738

2400

8640

24

700 x 400

10

19.6

10

20.6

250

900

2800

10080

28

800 x 400

10

21.1

10

22.2

273

983

3200

11520

32

1000 x 400

10

24.2

10

25.2

341

1228

4000

14400

40

1200 x 400

15

27.2

20

29.2 409

1473

4800

17280

48

1400 x 400

15

30.3

20

32.2

478

1721

5600

20160

56

1600 x 400

15

33.3

20

35.3 546

1966

6400

23040

64

500 x 500

10

18.5

10

19.5

214

771

2500

9000

25

600 x 500

10

20.5

10

21.6

257

926

3000

10800

30

700 x 500

10

22.6

10

23.6 300

1080

3500

12600

35

800 x 500

10

24.6

10

25.6

343

1235

4000

14400

40

1000 x 500

15

28.6

20

30.6

429

1545

5000

18000

50

1200 x 500

15

32.7

20

34.6

514

1851

6000

21600

60

1400 x 500

15

36.8

20

38.7 600

2160

7000

25200

70

1600 x 500

15

40.8

20

42.8

686

2470

8000

28800

80

600 x 600

10

22.7

10

23.7

309

1113

3600

12960

36

700 x 600

10

24.8

10

25.8

361

1300

4200

15120

42

800 x 600

15

26.8

20

27.8

412

1484

4800

17280

48

1000 x 600

15

30.9

20

32.9

515

1854

6000

21600

60

1200 x 600

15

35.0

20

37.0

618

2225

7200

25920

72

1400 x 600

15

39.2

20

41.1

722

2600

8,400 30240

84

1600 x 600

15

43.3

20

45.2

825

2970

9600

34560

96

700 x 700

15

27.6

20

29.5

422

1520

4900

17640

49

800 x 700

15

30.3

20

32.2

482

1736

5600

20160

56

1000 x 700

15

34.9

20

36.8 603

2171

7000

25200

70

1200 x 700

15

40.6

20

42.6

723

2603

8,400 30240

84

1400 x 700

15

45.7

20

47.7

844

3039

9800

35280

98

1600 x 700

15

51.0

20

52.9

964

3471

11200 40320

112

*

Installed according to the instructions

20

H

20

220

250

20

20

B

104

Figure 7. Dimensions, WISE Damper rectangular and WISE

Damper rectangular with spring return.

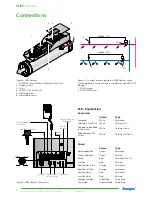

Installation – rectangular design

Dimension B in the figure and table below is found in the

table “Rectangular design” to the left.

NOTE! Damper spindles must be installed horizontally.

Straight section before WISE Damper in rectangular

ducts

Type of disruption

E (m

2

=5%)

E (m

2

=10%)

One 90° bend

E = 3 x B

E = 2 x B

T piece

E = 3 x B

E = 2 x B

Figure 5. Straight section requirements, rectangular ducts.

Figure 6. Straight section requirements, rectangular WISE

Damper and sound attenuator with baffle. Installation with

straight section applies both to supply and extract air.

1 = Rectangular WISE Damper.

2 = Straight duct

≥

500 mm.

3 = Sound attenuator with baffle.

Straight section before/after WISE Damper – sound

attenuator with baffle

E

H

B

E

H

B

1

2

3