7-2 SERVICING INFORMATION

TROUBLESHOOTING

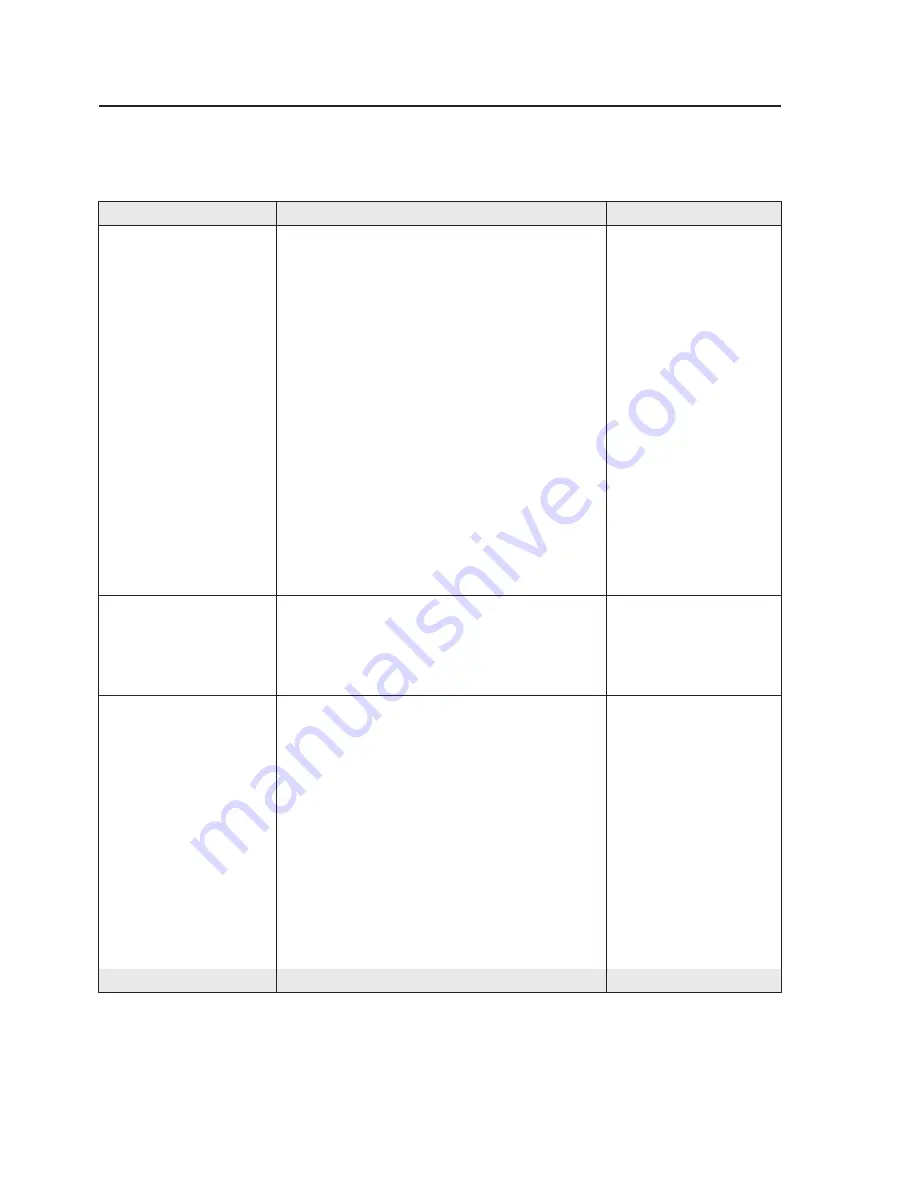

ENGINE

Complaint

Symptom and possible causes

Remedy

Engine will not start, or

is hard to start.

Compression too low

1. Out of adjustment valve clearance.

2. Worn valve guides or poor seating of valves.

3. Mistiming valves.

4. Excessively worn piston rings.

5. Worn-down cylinder bore.

6. Too slowly starter motor cranks.

7. Poor seating of spark plug.

Plugs not sparking

1. Fouled spark plug.

2. Wet spark plug.

3. Defective ignition coil.

4. Open or short in high-tension cord.

5. Defective pick-up coil or CDI unit.

No fuel reaching the carburetor

1. Clogged fuel tank air-vent hose.

2. Clogged or defective tap.

3. Defective carburetor needle valve

4. Clogged fuel hose, fuel filter or vacuum hose.

Adjust.

Repair or replace.

Adjust.

Replace.

Replace or rebore.

See electrical section.

Retighten.

Clean.

Clean and dry.

Replace.

Replace.

Replace.

Clean.

Clean or replace.

Replace.

Clean or replace.

Engine stalls easily.

1. Fouled spark plug.

2. Defective pick-up coil or CDI unit.

3. Clogged fuel hose.

4. Clogged jets in carburetor.

5. Out of adjustment valve clearance.

Clean.

Replace.

Clean.

Clean.

Adjust.

Noisy engine.

Excessive valve chatter

1. Too large valve clearance.

2. Weakened or broken valve springs.

3. Worn rocker arm or cam surface.

4. Worn and burnt camshaft journal.

Noise seems to come from piston

1. Worn down piston or cylinder.

2. Fouled with carbon combustion chamber.

3. worn piston pin or position pin bore.

4. Worn piston rings or ring grooves.

Noise seems to come from timing chain

1. Stretched chain.

2. Worn sprockets.

3. Not working tension adjuster.

Adjust.

Replace.

Replace.

Replace.

Replace.

Clean.

Replace.

Replace.

Replace.

Replace.

Repair or replace.

Complaint

Symptom and possible causes

Remedy

Содержание FD 110 XC

Страница 1: ...FD110 FD110 6 59 0 18 6 59 0 18 7...

Страница 5: ......

Страница 13: ...1 8 GENERAL INFORMATION...

Страница 32: ...PERIODIC MAINTENANCE 2 19 1 5 9 13 14 6 11 8 7 10 12 2 3...

Страница 81: ...3 46 ENGINE...

Страница 96: ...FUEL AND LUBRICATION SYSTEM 4 15 LUBRICATION SYSTEM...

Страница 98: ...FI SYSTEM DIAGNOSIS 5 2...

Страница 100: ...CHASSIS 5 4 FRONT HANDLEBAR S COVER REAR HANDLEBAR S COVER...

Страница 163: ...6 30 ELECTRICAL SYSTEM...

Страница 178: ...SERVICING INFORMATION 7 15 FUEL HOSE ROUTING FUEL TANK CLAMP...

Страница 179: ...7 16 SERVICING INFORMATION BATTERY BATTERY BREATHER HOSE FUEL TANK...

Страница 180: ...SERVICING INFORMATION 7 17 FRONT WHEEL SET UP DRUM TYPE 4 0 K 0 8 KG M mm 7 86 14 O...

Страница 181: ...7 18 SERVICING INFORMATION FRONT WHEEL SET UP DISK TYPE 2 3 K G M 2 6 K G M 2 3 K G M 4 0 K G M...

Страница 182: ...SERVICING INFORMATION 7 19 REAR WHEEL SET UP 5 4 KG M 0 8 KG M 114 8 mm...