4

2.1

POSITIONING THE FURNACE

WARNING

Fire and explosion hazard.

The furnace must be installed in a level position, never

where it will slope toward the front.

Do not store or use gasoline or any other flammable

substances near the furnace

Non-observance of these instructions will potentially result

in death, bodily injury and/or property damage.

CAUTION

This furnace is not watertight and is not designed for

outdoor installation. It must be installed in such a manner

as to protect its electrical components from water.

Outdoor installation will lead to a hazardous electrical

condition and to premature failure of the equipment

If the furnace is installed in a basement or on a dirt floor, in a

crawl space for example, it is recommended to install the unit on

a cement base 2.5 cm to 5.0 cm (1’’ to 2’’) thick.

The unit must be installed in an area where the ambient and

return air temperatures are above 15˚C (60˚F). In addition, the

heater should also be located close to the center of the air

distribution system.

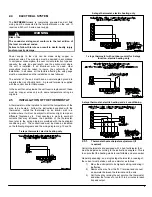

2.2 CLEARANCES TO COMBUSTIBLE

MATERIAL

2.2.1. Heating

unit

The furnace is approved for zero clearance to combustible

material regardless of the heating capacity.

2.2.2.

Supply air ducts

Ducts for furnaces with a heating capacity up to and including

20 k W, can be installed with a zero clearance to combustible

material.

Ducts for furnaces of 23 kW or more must have a clearance of

25 mm (1’’) to combustible material for the first 0.9 m (36’’) of

duct. Thereafter the clearance can be zero.

Units of 23 kW and up, installed in the downflow position must

use a DFB-FEM downflow base, which is especially designed

for this purpose. It ensures that the required clearances are

being adhered to.

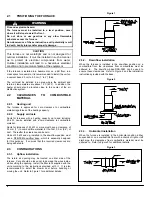

2.3 CONFIGURATIONS

2.3.1. Upflow

installation

The return air opening may be located on either side of the

furnace. Care should be taken not to damage the wires inside,

while cutting the opening. Install the filter rack supplied with the

unit according to the instructions provided with it. It is also

recommended to install the blower door before handling or

moving the unit. Refer to Figure 1 for additional details.

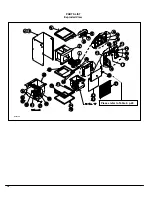

Figure 1

2.3.2. Downflow

installation

When the furnace is installed in the downflow position on a

combustible floor, the clearances from combustibles must be

adhered to. The downflow base DFB-FEM can be used to

ensure these clearances. Refer to Figure 2 and the installation

instructions provided with the base.

Figure 2

2.3.3. Horizontal

installation

When the furnace is installed in the horizontal position, either

suspended or on a combustible floor with a choice of right or left

discharge, the clearances from combustible material must be

adhered to. Refer to Figure 3 for additional details.

Figure 3

Содержание FEM10-M2301CM-A

Страница 12: ...12 FIGURE 6 Diagramme lectrique 10 kW avec moteur 1 3 HP...

Страница 13: ...13 FIGURE 7 Diagramme lectrique 15 kW avec moteur 1 3 HP...

Страница 14: ...14 FIGURE 8 Diagramme lectrique 18 kW avec moteur 1 3 HP et 20 kW avec moteur 1 3 HP et 1 HP...

Страница 15: ...15 FIGURE 9 Diagramme lectrique 23 kW avec moteur 1 3 HP et 1 HP...

Страница 16: ...16 FIGURE 10 Diagramme lectrique 27 kW avec moteur 1 HP...

Страница 17: ...17 COMPOSANTES ET PI CES DE REMPLACEMENT...

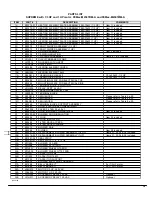

Страница 18: ...18 LISTE DE PI CES Vue explos e B50079B Se r f rer au tableau 4 p 20...

Страница 32: ...12 FIGURE 6 Wiring Diagram 10 kW with 1 3 HP motor...

Страница 33: ...13 FIGURE 7 Wiring Diagram 15 kW with 1 3 HP motor...

Страница 34: ...14 FIGURE 8 Wiring Diagram 18 kW with 1 3 HP motor and 20 kW with 1 3 HP and 1 HP motor...

Страница 35: ...15 FIGURE 9 Wiring Diagram 23 kW with 1 3 HP and 1 HP motor...

Страница 36: ...16 FIGURE 10 Wiring Diagram 27 kW with 1 HP motor...

Страница 37: ...17 COMPONENTS AND REPLACEMENT PARTS...

Страница 38: ...18 PARTS LIST Exploded View B50079A Please refer to Table 4 p 20...