24

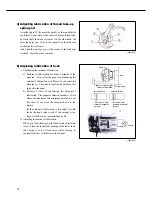

b) Adjusting the thread trimming solenoid

①

First, loosen the solenoid link pin fixing screw. Later, fix the solenoid base clamp screw where the clutch lever

moves smoothly. Then, attach the slide arm to the right side. Fix the thread trimming solenoid link pin fixing

screw where the solenoid stopper is attached to the solenoid.

②

If you run the solenoid under this circumstance, a gap of 0.5mm occurs between the thread trimming following

crank and the slide arm as shown in Figure 39. This state is the standard.

[Figure 39]

solenoid link fixing screw

solenoid link pin

solenoid base

solenoid base

fixing screw

thread release cable fixing nut

thread trimming following crank

solenoid arm

[Figure 40]

Adjusting the thread trimming cam

a) Like in Figure 40, align the second timing carved

line (Green) of the pulley with the arm

’

s carved

line.

green

carve

line

carve

line

[Figure 41]

b) Under the thread trimming solenoid is in operation,

rotate the trimming cam clockwise and fix the cam

when it connected with the roller. (Refer to Figure

41)

c) When the thread cam following crank returned by

stopping the operation of the thread trimming

solenoid, the edge end between the cam and the

roller should be from 0.5 to 1.0mm. It is the

standard. (Refer to Figure 40)

0.5~1mm

Содержание KM-640BL

Страница 29: ...29 5 Table Drawing 1 KM 640BL ...

Страница 30: ...30 2 KM 640BL 7 ...