15

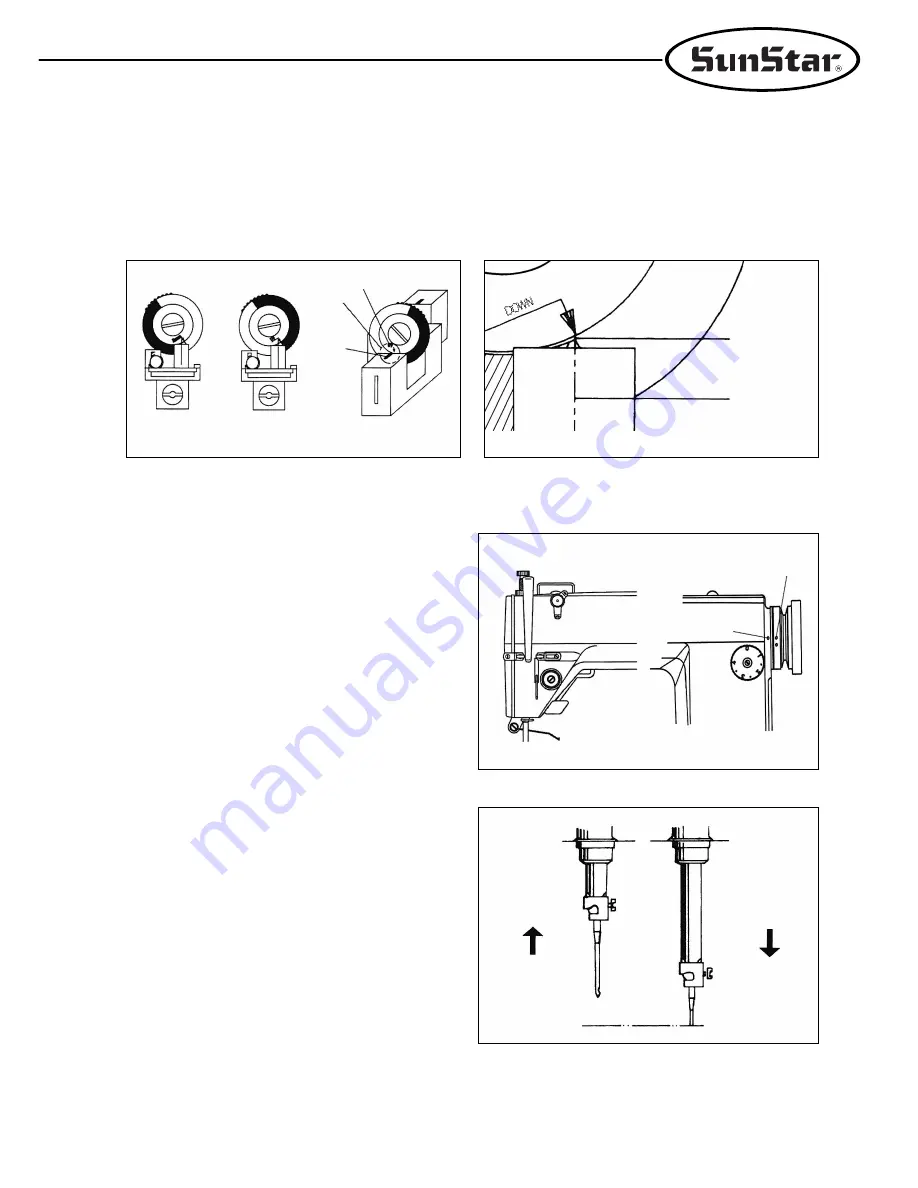

B. For 470 motor (external location detectors)

Turn the pulley manually to position the needle bar at the lowest point about to move back up. Then, loosen the fixed screws on

the film as in Fig. 11 and align the “DOWN” film with the film adjustment baseline and the sensor housing baseline as in Fig.

15&16. Tighten the fixed screws just enough so that the film does not rotate. In the same way, place the thread take-up lever at

the highest point, then loosen the fixed screws again and adjust the “UP” film as in shown the figure. Be careful that the

“DOWN” film A that was tightened before does not move when adjusting the “UP” film.

Figure 16 enlarges the film position. As can be seen in figure 16, set the end of film-adjusting arrow to sensor base.

[Figure 15]

[Figure 16]

Setting the film when

the needle is in a up-

stop position

Setting the film when the

thread take-up lever is at

the highest point

Film-Adjusting Arrow

Setting Area

Sensor

Baseline

Film Adjusting

Base

Sensor Base

9) Check for the stop position of the machine

Check for the machine stop position after moving the needle up

and down by pushing the reverse button. See whether the

carved sign on the arm and the white carved sign on the pulley

are aligned when the needle is in an up position. If not,

adjustment to the photo film of the location detector or to the

location of the magnetic holder will be necessary since there

may be problems with the trimming. In other words, the

needle’s up-stop position should be identical with the stop

position of the needle bar after the trimming operation, which

would signify that there is nothing wrong with the operation

timing of the trimmer. (See Figure 17) (Refer to the explanation

about the Adjustment of Location Detector on page 13.)

[Figure 17]

White carved sign

10) Explanation of reverse button function

Pressing the back tack button or reverse button during forward

sewing will start reverse sewing immediately. When you stop

the machine and restart it by stepping down on the pedal with

the reverse button already pressed down, you can perform

reverse sewing from the beginning. When the machine is in a

“stop” mode, you can change the up-down position of the

needle bar by pressing the reverse button. Lightly pressing the

button once when the needle is in a down-stop position will stop

the needle bar in a high position. Pressing the reverse button

twice within less than a second when it is in an up-stop position

will stop the needle bar in a low position. In short, the button

delivers two functions: one for reverse sewing and the other for

converting vertical position of the needle. (See Figure 18)

[Figure 18]

Down-stop

Up-stop

Arm carved sign

Reverse button