930487 Rev. B

I X . S e t - U p & A d j u s t m e n t

35

I X . S e t - U p & A d j u s t m e n t

930487 Rev. B

34

L. WHEEL LOCKS

NOTE–

Use a torque setting of 100 in.-lbs when set-

ting-up wheel locks.

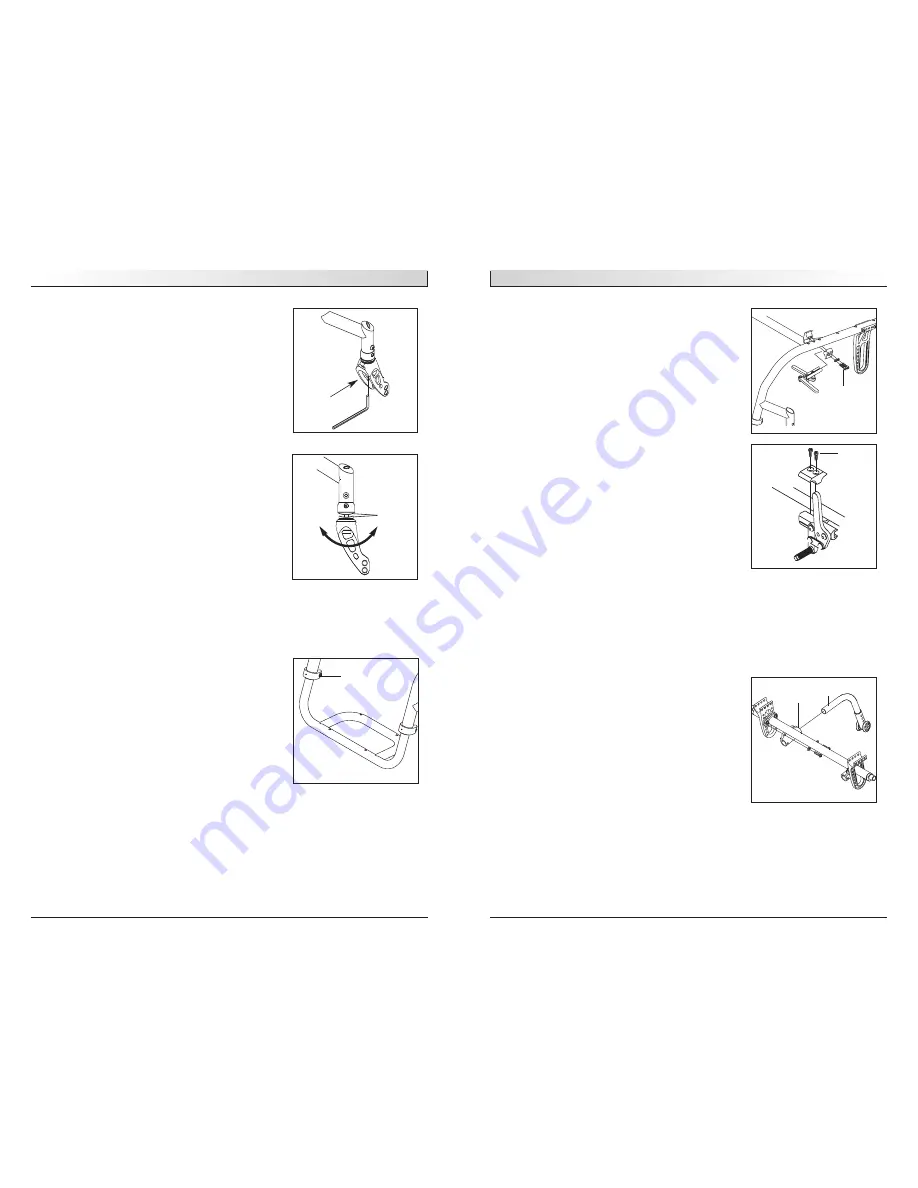

1. High-Mount Scissor Wheel Locks:

Loosen the screws (A) on the top of each clamp using

a 3/16 Allen wrench. Slide assembly toward rear wheel

until clamp embeds into tire to prevent wheel move-

ment when in locked position. Adjust angle position.

Tighten screws.

NOTE–

Clamp and wheel lock may need to be rotated

to clear frame tubing.

2. High-Mount Push-to-Lock or Pull-to-Lock

Wheel Locks

Loosen the screws (B) on the top of each clamp using a

3/16" Allen wrench. Slide clamp toward the rear wheel

until the wheel lock is embedded into the tire to pre-

vent wheel movement, when in the locked position.

Adjust angle position. Tighten screws.

M. ANTI-TIP TUBES (OPTIONAL)

Sunrise Medical recommends anti-tip tubes for all

wheelchairs.

Use torque setting of 65 in-lbs.

(7.3 Nm) when installing anti-tip tubes.

1. Inserting Anti-tip Tubes Into Receiver

a. Press the rear anti-tip release lever on the anti-tip

tube so that both release pins are drawn inside.

b. Insert the anti-tip tube (C) into the anti-tip

receiver (D).

c. Turn the anti-tip tube down until release pin is

through the receiver mounting hole.

d. Insert second anti-tip tube the same way.

2. Adjusting Anti-Tip Tube Wheel

The anti-tip wheels may have to be raised or lowered

to achieve proper clearance of 1 1/2" to 2".

Press the anti-tip wheel release button so that both

release pins are drawn inside. Raise or lower to one of

the three predrilled holes. Release button. Adjust the

second anti-tip tube wheel the same way. Both wheels

should be exactly the same height.

Loosen the stem bolt (A) on the right fork using an

8mm Allen wrench. Do not remove the stem bolt.

Simply loosen it enough to allow the teeth on the

upper and lower splines to clear one another (B). With

the stem bolt loosened, the caster fork should pivot

freely. Place the wheelchair on the floor so that the two

rear wheels and left caster contact the floor. Place some

weight in the seat towards the rear to help stabilize the

chair. Place a square or pocket level against the flat

surface of the fork and pivot the fork until it is vertical

(square). With the fork vertical, engage the teeth of the

two splines to the closest mating position. Make certain

that the teeth are properly engaged and not crossed.

Shine a bright light behind the mating spline teeth and

check for proper teeth engagement. Tighten the stem

bolt to secure the spline mating position. The stem bolt

should be tightened to 20 ft-lbs to ensure that it does

not loosen during use.

Record the teeth engagement position of the splines

on the right fork, and adjust the left fork in a similar

fashion to the same position. Reassemble both casters,

and re-check that they are square.

K. FOOTREST HEIGHT ADJUSTMENT

NOTE–

Use a torque setting of 150 in.-lbs. (17 Nm)

when adjusting footrest height.

To adjust the height of your footrest, loosen the two

cap screws (C) on the footrest clamps. Slide the

footrest up or down to the new desired height and

tighten the two cap screws. Use a torque setting of

150 in-lbs (17 Nm). It is recommended that you main-

tain a minimum of 2.0 inches (5 cm) between the low-

est point on the footrest and the floor. This will pro-

vide adequate clearance for uneven surfaces and pre-

vent damage to your footrest.

C

A

B

D

C

A

B