Removing and Replacing System Boards and Assemblies

2-13

2

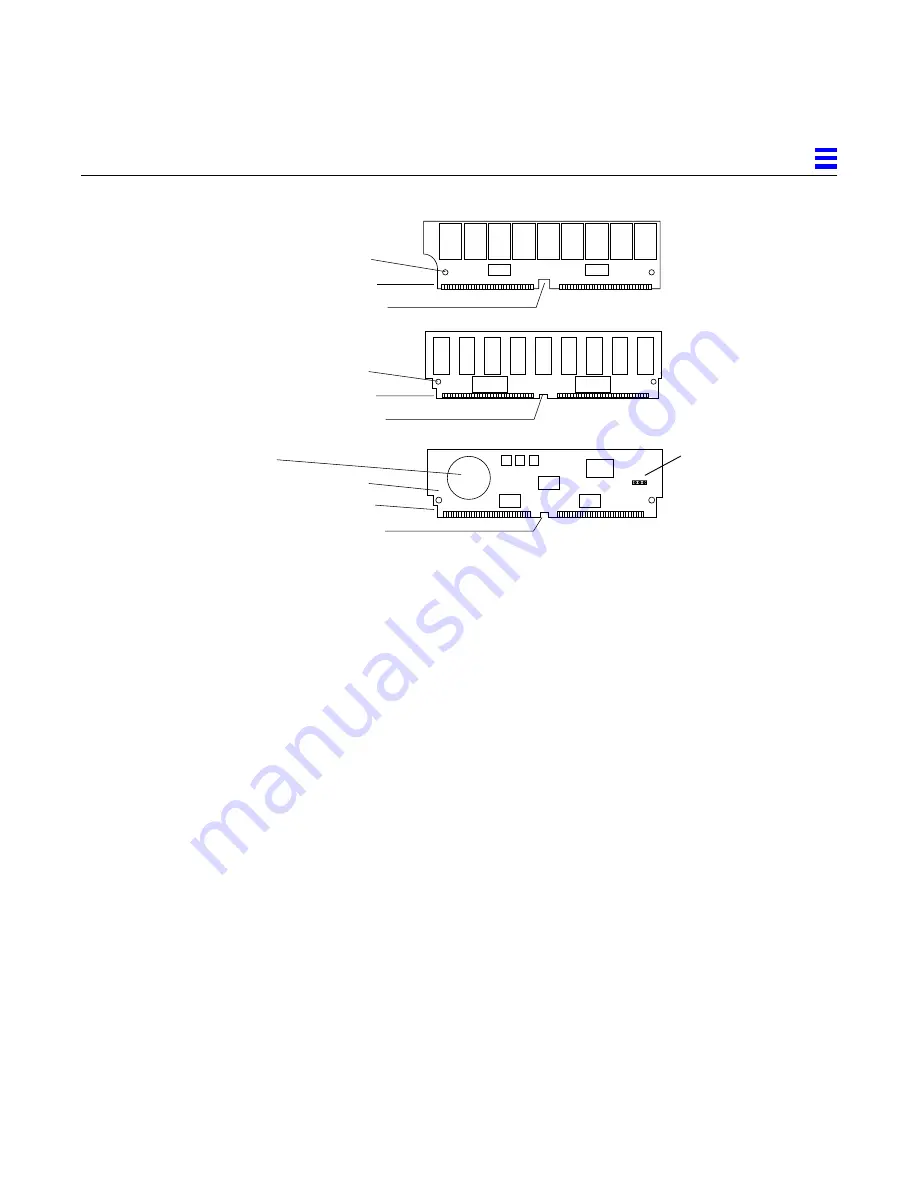

Figure 2-12 SIMM Types

2.6.1 Removal

If a SIMM or NVSIMM fails, the power-on self test (POST) will identify the

location number (also known as the U-number or J-number) of the failing

device. The socket number (J-number) is printed on the back of the board.

When replacing faulty SIMMs, refer to the location-numbers listed below.

1. Locate a faulty SIMM by matching the location number noted in the

POST message.

2. Orient the system board so that the XDBus™ connectors face you.

3. Unlock the SIMM by pressing the locking tabs toward the sides of the

socket and then tilting the SIMM forward, as shown in Figure 2-14.

4. For most SIMM sockets, there is very little space for movement, so unlock

two more SIMMs in front of the first SIMM, as shown in Figure 2-15.

This allows the faulty SIMM to tilt forward far enough to disengage the

locking pins.

5. Remove the SIMM from the socket and place it in an antistatic bag.

1

34

35

68

1

34

35

68

Type A

Type B

Alignment notch, bottom

Alignment hole (1 of 2)

Alignment notch, large

Alignment notch, bottom

Alignment hole (1 of 2)

Alignment notch, large

1

34

35

68

Battery

Type C

(NVSIMM)

Alignment notch, bottom

Alignment hole (1 of 2)

Alignment notch, large

Jumper