Section 6

COMPRESSOR OPERATION

23

6.1 GENERAL

While Sullair has built into the DR---13 compressor

package a comprehensive array of controls and in-

dicators to help assure proper operation, the user

should recognize and interpret readings which call

for service or indicate the onset of a malfunction.

Before starting the unit, the user should become fa-

miliar with the controls and indicators --- their pur-

pose, location, and use.

WARNING

!

The minimum continuous operating pressure is

70 psig (4.8 bar). the compressor should not be

operated below this pressure except for short pe-

riods. The Supervisor

II

will shut the machine

down if it is operated continuously below 50 psig

(3.4 bar) for five minutes.

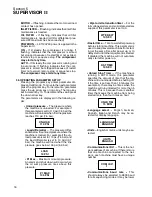

6.2 PURPOSE OF CONTROLS

CONTROL OR INDICATOR

PURPOSE

EMERGENCY STOP SWITCH

Pushing in this switch, found adjacent to the Supervisor

II

, cuts all AC outputs from the latter and de---energizes

the starter. A fault message (E STOP) is displayed by

the Supervisor

II

until the button is pulled out and the

“O”

pad is pressed.

MOTOR O/L RESET

Momentarily pushing this button, found on the thermal

overload element housing in the starter box, re---closes

the latter’s contacts after a current overload takes place.

Please be aware that the elements must be allowed to

cool sufficiently before resetting.

LIMIT SWITCH

Operates blowdown valve.

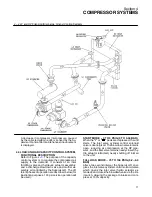

DISCHARGE CHECK VALVE

Isolates compressor from field pipework when shut

down. Located between the HPsilencer and the after-

cooler.

PRESS RELIEF VALVES

Found on the discharge pipework of both LP and HP

stages, they vent the compressed air to atmosphere in

case of an over pressure condition --- 65 and 165 psi

(4.5 and 11.4 bar), respectively.

INLET VALVE CYLINDER AND CONTROL VALVE

ASSEMBLY

The hydraulically operated butterfly valve throttles the

air flow entering the unit inlet flange --- LP stage. A

4---way electric solenoid valve loads and unloads the hy-

draulic actuator, in response to Supervisor

II

com-

mands.

BLOWDOWN VALVES

The 2---way valve vents compressed air (HP discharge)

to atmosphere through a muffler.

DRAIN GLOBE VALVES

Furnished as manual backups to automatic drain valves

used in the condensate separator vessels. Also used as

lubricant sump drain valve.

OIL PRESSURE BYPASS VALVE

To maintain desired oil flow

and

to protect oil pump from

over pressure situations.

THERMAL VALVE

This thermal valve automatically opens/closes to by-

pass warm oil around the heat exchanger to ensure fast

oil warmup and optimize operating temperature.

SUMP SIGHT GLASS

Indicates level of lubricant in the sump. Located on the

sump side, it should show 75% full (compressor

stopped) for proper oil level.

Содержание DR-13 Series

Страница 6: ...NOTES ...

Страница 14: ...8 NOTES ...

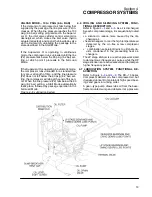

Страница 18: ...Section 4 COMPRESSOR SYSTEMS 12 Figure 4 5 Piping and Instrumentation Diagram Air cooled ...

Страница 21: ...Section 5 SUPERVISOR II 15 Figure 5 1 Supervisor II Panel ...

Страница 28: ...22 NOTES ...

Страница 32: ...26 NOTES ...

Страница 42: ...Section 7 MAINTENANCE 36 Table 1 Installation Data ...

Страница 46: ...40 NOTES ...

Страница 48: ...Section 9 ILLUSTRATIONS AND PARTS LIST 42 9 3 COMPRESSOR MOTOR AND FRAME ...

Страница 50: ...Section 9 ILLUSTRATIONS AND PARTS LIST 44 9 4 AIR INLET SYSTEM ...

Страница 52: ...Section 9 ILLUSTRATIONS AND PARTS LIST 46 9 5 COOLER ASSEMBLY ...

Страница 54: ...Section 9 ILLUSTRATIONS AND PARTS LIST 48 9 6 LP HOT LP COLD ...

Страница 56: ...Section 9 ILLUSTRATIONS AND PARTS LIST 50 9 7 HP DISCHARGE ...

Страница 58: ...Section 9 ILLUSTRATIONS AND PARTS LIST 52 9 8 LUBE SYSTEM ...

Страница 60: ...Section 9 ILLUSTRATIONS AND PARTS LIST 54 9 9 ELECTRICAL BOX ...

Страница 62: ...Section 9 ILLUSTRATIONS AND PARTS LIST 56 9 10 CONTROL SYSTEM CONDENSATE DRAIN ...

Страница 64: ...Section 9 ILLUSTRATIONS AND PARTS LIST 58 9 11 CANOPY ...

Страница 66: ...Section 9 ILLUSTRATIONS AND PARTS LIST 60 9 12 DECALS ...

Страница 68: ...Section 9 ILLUSTRATIONS AND PARTS LIST 62 9 12 DECALS ...

Страница 70: ...Section 9 ILLUSTRATIONS AND PARTS LIST 64 9 12 DECALS ...

Страница 72: ...Section 9 ILLUSTRATIONS AND PARTS LIST 66 9 13 DECAL LOCATIONS ...

Страница 74: ...Section 9 ILLUSTRATIONS AND PARTS LIST 68 9 13 DECAL LOCATIONS ...

Страница 76: ...Section 9 ILLUSTRATIONS AND PARTS LIST 70 9 13 DECAL LOCATIONS ...

Страница 78: ...Section 9 ILLUSTRATIONS AND PARTS LIST 72 9 14 WIRING DIAGRAM ...

Страница 79: ...NOTES ...