SECTION 1

7

E.

Flow-limiting valves are listed by pipe size and

rated CFM. Select appropriate valve accordingly.

F. DO NOT

use tools that are rated below the maxi-

mum rating of this compressor. Select tools, air

hoses, pipes, valves, filters and other fittings

accordingly.

DO NOT

exceed manufacturer’s

rated safe operating pressures for these items.

G.

Secure all hose connections by wire, chain or

other suitable retaining device to prevent tools or

hose ends from being accidentally disconnected

and expelled.

H.

Open fluid filler cap only when compressor is not

running and is not pressurized. Shut down the

compressor and bleed the sump (receiver) to

zero internal pressure before removing the cap.

I.

Vent all internal pressure prior to opening any

line, fitting, hose, valve, drain plug, connection or

other component, such as filters and line oilers,

and before attempting to refill optional air line

anti-icer systems with antifreeze compound.

J.

Keep personnel out of line with and away from

the discharge opening of hoses, tools or other

points of compressed air discharge.

K. DO NOT

use air at pressures higher than 30 psig

(2.1 bar) for cleaning purposes, and then only

with effective chip guarding and personal protec-

tive equipment per OSHA Standard 29 CFR

1910.242 (b) or any applicable Federal, State

and Local codes, standards and regulations.

L. DO NOT

engage in horseplay with air hoses as

death or serious injury may result.

M.

This equipment is supplied with an ASME

designed pressure vessel protected by an ASME

rated relief valve. Lift the handle once a week to

make sure the valve is functional.

DO NOT

lift

the handle while machine is under pressure.

N.

If the machine is installed in an enclosed area it

is necessary to vent the relief valve to the outside

of the structure or to an area of non-exposure.

O. DO NOT

remove radiator filler cap until the cool-

ant temperature is below its boiling point. Then

loosen cap slowly to its stop to relieve any

excess pressure and make sure coolant is not

boiling before removing cap completely. Remove

radiator filler cap only when cool enough to touch

with a bare hand.

P.

The ethyl ether in the replaceable cylinders used

in diesel ether starting aid systems (optional) is

under pressure.

DO NOT

puncture or incinerate

those cylinders.

DO NOT

attempt to remove the

center valve core or side pressure relief valve

from these cylinders regardless of whether they

are full or empty.

Q.

If a manual blowdown valve is provided on the

receiver, open the valve to ensure all internal

pressure has been vented prior to servicing any

pressurized component of the compressor air/

fluid system.

1.4

FIRE AND EXPLOSION

A.

Refuel at a service station or from a fuel tank

designed for its intended purpose. If this is not

possible, ground the compressor to the dis-

penser prior to refueling.

B.

Clean up spills of fuel, fluid, battery electrolyte or

coolant immediately if such spills occur.

C.

Shut off air compressor and allow it to cool. Then

keep sparks, flames and other sources of ignition

away and

DO NOT

permit smoking in the vicinity

when adding fuel, checking or adding electrolyte

to batteries, checking or adding fluid, checking

diesel engine ether starting aid systems, replac-

ing cylinders, or when refilling air line anti-icer

systems antifreeze compound.

D. DO NOT

permit liquids, including air line anti-icer

system antifreeze compound or fluid film, to

accumulate on bottom covers or on, under or

around acoustical material, or on any external or

internal surfaces of the air compressor. Wipe

down using an aqueous industrial cleaner or

steam clean as required. If necessary, remove

acoustical material, clean all surfaces and then

replace acoustical material. Any acoustical mate-

rial with a protective covering that has been torn

or punctured should be replaced immediately to

prevent accumulation of liquids or fluid film within

the material.

DO NOT

use flammable solvents

for cleaning purposes.

WARNING

Do not attempt to operate the compressor

in any classification of hazardous environ-

ment or potentially explosive atmosphere

unless the compressor has been specially

designed and manufactured for that duty.

Содержание 300HH

Страница 17: ...SECTION 1 15 Safety Symbols 2 ...

Страница 18: ...SECTION 1 16 Safety Symbols 3 ...

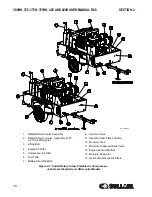

Страница 26: ...300HH 375 375H 375HH 425 AND 425H USER MANUAL R00 SECTION 2 24 Figure 2 6 Piping and Instrumentation ...

Страница 28: ...300HH 375 375H 375HH 425 AND 425H USER MANUAL R00 SECTION 2 26 Figure 2 7 Piping and Instrumentation ...

Страница 49: ...SECTION 2 300HH 375 375H 375HH 425 AND 425H USER MANUAL R00 47 2 9 WIRING DIAGRAM ...

Страница 60: ...NOTES 58 ...

Страница 79: ...NOTES ...