SECTION

1

4

A.

Prior to hitching the air compressor to the tow

vehicle, inspect all attachment parts and equip-

ment, checking for (i) signs of excessive wear or

corrosion, (ii) parts that are cracked, bent,

dented or otherwise deformed or degraded, and

(iii) loose nuts, bolts or other fasteners. Should

any such condition be present,

DO NOT TOW

until the problem is corrected.

B.

Back the tow vehicle to the compressor and posi-

tion it in preparation for coupling the compressor.

C.

If the compressor is provided with a drawbar

latched in the vertical upright position, carefully

unlatch drawbar and lower it to engage the cou-

pling device. If not, raise drawbar with the jack to

engage coupling device or otherwise couple the

compressor to the towing vehicle.

D.

Make sure the coupling device is fully engaged,

closed and locked.

E.

If chains are provided, pass each chain through

its point of attachment on the towing vehicle;

then hook each chain to itself by passing the

grab hook over (not through) a link. Cross chains

under the front of drawbar before passing them

through points of attachment on towing vehicle to

support the front of drawbar in case it should

accidentally become uncoupled.

F.

Make sure that the coupling device and adjacent

structures on the towing vehicle (and also, if uti-

lized, chain adjustment, brake and/or electrical

interconnections)

DO NOT

interfere with or

restrict motion of any part of the compressor,

including its coupling device, with respect to the

towing vehicle when maneuvering over any

anticipated terrain.

G.

If provided, make sure chain length, brake and

electrical interconnections provide sufficient

slack to prevent strain when cornering and

maneuvering, yet are supported so they cannot

drag or rub on road, terrain or towing vehicle sur-

faces which might cause wear that could render

them inoperative.

H.

On two-wheeled models, fully retract front screw

jack and any rear stabilizer legs. If a caster wheel

is provided on the screw jack it is part of the

screw jack, and can not be removed. Follow the

same procedure for stowing away the wheeled

jack as you would for the standard screw jack.

Pull the pin connecting the jack to the drawbar

and raise the screw jack to its full upright posi-

tion. Rotate the screw jack to its stowed position,

parallel to the drawbar, and reinsert the pin.

Make sure the jack is secured in place prior to

towing.

WARNING

This equipment may be tongue heavy. DO

NOT attempt to raise or lower the drawbar

by hand if the weight is more than you can

safely handle.

Use the screw jack provided or a chain fall

if you cannot lift or lower it without avoiding

injury to yourself or others. Keep hands

and fingers clear of the coupling device and

all other pinch points. Keep feet clear of

drawbar to avoid injury in case it should

slip from your hands.

WARNING

This equipment may be tongue heavy. DO

NOT attempt to raise or lower the drawbar

by hand if the weight is more than you can

safely handle.

CAUTION

Retract the front screw jack only after

attaching the compressor to the tow vehi-

cle. Raise the screw jack to its full up posi-

tion and pull the pin connecting the jack to

the drawbar. Rotate the screw jack to its

stowed position, parallel to the drawbar,

and reinsert the pin. Make sure the jack is

secured in place prior to towing.

If a caster wheel is provided on the screw

jack it is part of the screw jack and can not

be removed. Follow the same procedure for

stowing away the wheeled jack as you

would for the standard screw jack. Pull the

pin connecting the jack to the drawbar and

raise the screw jack to its full up position.

Rotate the screw jack to its stowed posi-

tion, parallel to the drawbar, and reinsert

the pin. Make sure the jack is secured in

place prior to towing.

Содержание 300HH

Страница 17: ...SECTION 1 15 Safety Symbols 2 ...

Страница 18: ...SECTION 1 16 Safety Symbols 3 ...

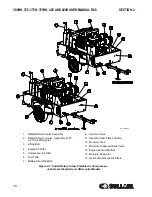

Страница 26: ...300HH 375 375H 375HH 425 AND 425H USER MANUAL R00 SECTION 2 24 Figure 2 6 Piping and Instrumentation ...

Страница 28: ...300HH 375 375H 375HH 425 AND 425H USER MANUAL R00 SECTION 2 26 Figure 2 7 Piping and Instrumentation ...

Страница 49: ...SECTION 2 300HH 375 375H 375HH 425 AND 425H USER MANUAL R00 47 2 9 WIRING DIAGRAM ...

Страница 60: ...NOTES 58 ...

Страница 79: ...NOTES ...