3000PB, 3700B, 4500B, 3000PVB, 3700VB, 4500VB User Manual

6: Maintenance

02250216-786 R01

Subject to EAR, ECCN EAR99 and related export control restrictions.

57

6.8

Separator maintenance

Replace the separator element when indicated by the

WS Controller™ or after one (1) year, whichever comes

first. The separator element must be replaced.

Do not

attempt to clean the separator element.

6.8.1

Separator element replacement

. The separator element must be

changed when indicated by the WS Controller, or once a

year, whichever occurs first. Follow the procedure

explained below for separator element replacement.

1. Loosen and remove the eight (8) hex head

capscrews (½ in × 1¾ in) from the cover

plate.

2. Lift the cover plate from the separator/sump

tank.

3. Remove the separator element.

4. Inspect the separator/sump tank for rust, dirt,

etc.

5. Reinsert the separator element into the sep-

arator/sump tank taking care not to dent the

element against the tank opening.

6. Install a new lubricated O-ring in the O-ring

groove on the underside of the separator/

sump tank cover.

7. Replace the cover plate, washers and cap-

screws. Torque to 80 ft·lbs. (108 N·m).

8. Clean the return line strainer before restart-

ing the compressor.

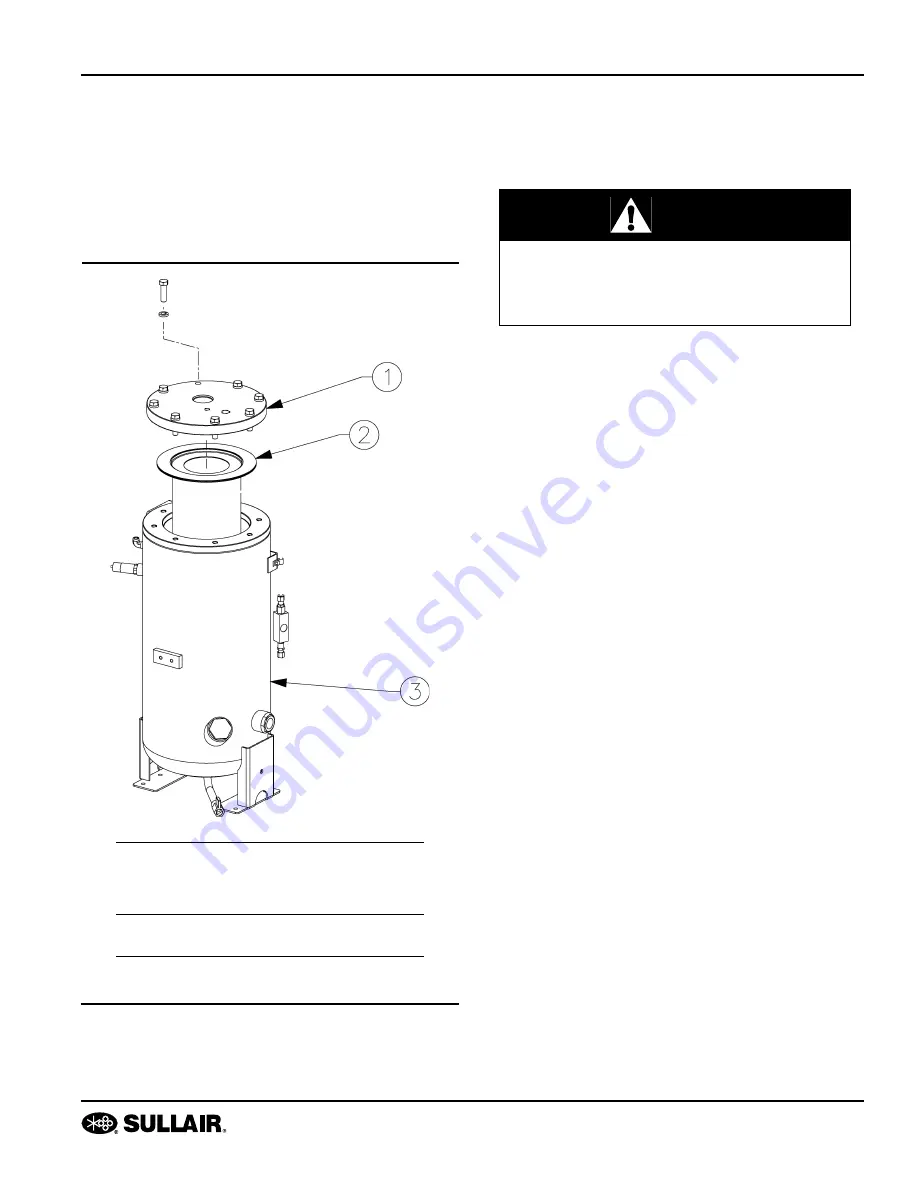

Figure 6-3: Separator element assembly

1. Cover

2. Element

1

3. Separator/sump tank

1

Separator element replacement kit P/N: 02250217-256

Separator element P/N: 02250214-587

WARNING

High-pressure hazard.

Relieve all pressure from the separator/sump

tank and all compressor lines.