5: Maintenance

185 T3 Kubota User Manual

02250223-054 R01

44

Subject to EAR, ECCN EAR99 and related export control restrictions.

3. Adjust the pressure regulator so that the

compressor maintains 115 psig (8 bar).

4. Gradually open the service valve to atmo-

sphere until the engine comes up in speed

and sump pressure is held at 100 psig

(6.9 bar). At this point, set the engine high

speed to its specified setting by adjusting the

high idle threaded rod located on the engine

speed control. To raise or lower the speed,

lengthen or shorten the rod respectively.

5. Open the service valve to 100 psig (6.9 bar)

(rated full load pressure) and recheck top

engine speed and control response. Close

the service valve and allow the compressor

to cycle and re-check low engine speed

(idle).

5.9.7

Bearing lubrication

. Proper lubrication of the portable

compressor’s bearing axle is critical to its proper function

and reduction of wear on this part. Wheel bearings

should be lubricated at least every 12 months, or more,

to ensure proper performance and minimize wear. Use a

wheel bearing grease that conforms to MILSPEC MIL-G-

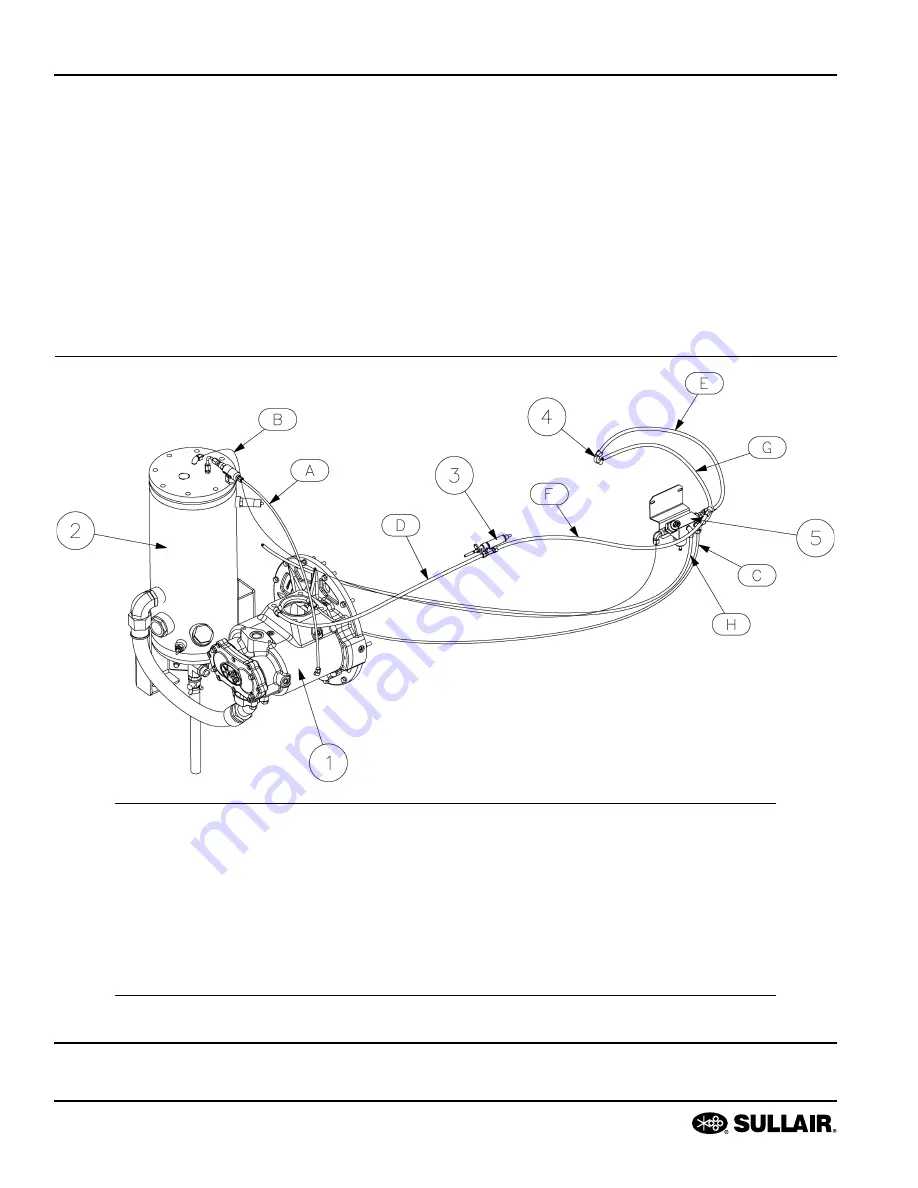

Figure 5-5: Control system adjustment

1. Compressor unit

A. .25 OD white

2. Receiver tank

B. .38 OD blue

3. Engine speed control cylinder

C. .25 OD black

4. Warm-up control valve

D. .38 OD green

5. Pressure regulator / blowdown manifold

E. .38 OD orange

F. .38 yellow

G. .38 OD red

H. .31 OD white (to fitting at unit air filter)