AIR CARE

SEMINAR TRAINING

Sullair Air Care Seminars are 3---day courses that provide hands---on instruction

in the proper operation, maintenance and service of Sullair equipment.

Individual seminars on Industrial compressors and compressor electrical

systems are presented at regular intervals throughout the year at a dedicated

training facility at Sullair’s corporate headquarters in Michigan City, Indiana.

Instruction includes discussion of the function and installation of Sullair service

parts, troubleshooting of the most common problems, and actual equipment

operation. The seminars are recommended for maintenance and service

personnel.

For detailed course outlines, schedule and cost information contact:

Sullair Corporate Training Department

1---800---348---2722 or 219---879---5451 (ext. 1867)

--- Or Write ---

Sullair Corporation

3700 E. Michigan Blvd.

Michigan City, IN 46360

Attn: Service Training Department

Содержание 10B 25HP

Страница 2: ...NOTE For Additional Information on 24KT Units See Inside Back Cover...

Страница 4: ...NOTES...

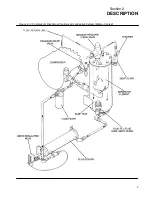

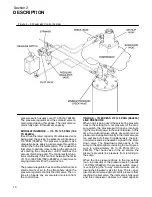

Страница 13: ...Section 2 DESCRIPTION 7 Figure 2 3 Compressor Discharge Cooling and Lubrication System Water Cooled...

Страница 22: ...16 NOTES...

Страница 24: ...Section 4 INSTALLATION 18 Figure 4 1 Piping and Instruments...

Страница 26: ...20 NOTES...

Страница 42: ...36 NOTES...

Страница 44: ...NOTES...

Страница 45: ......