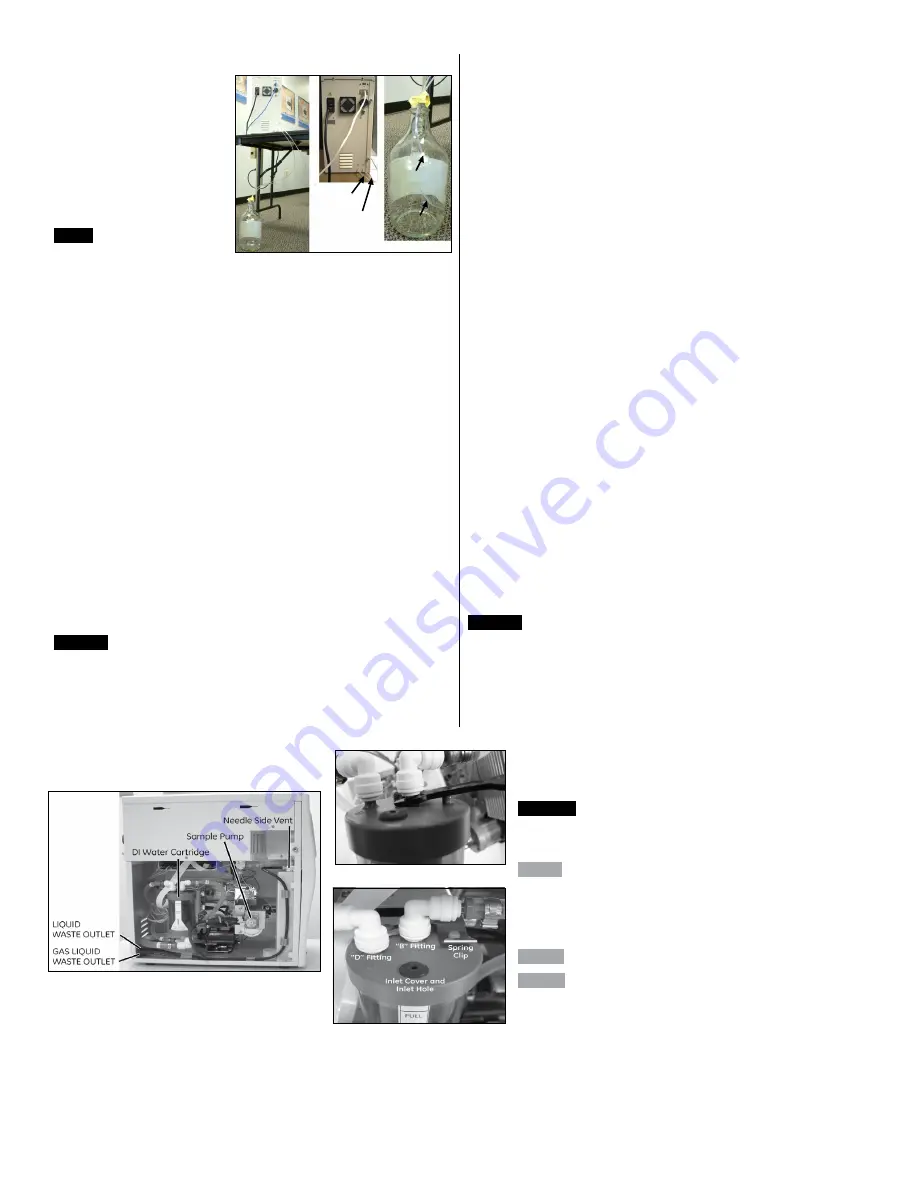

Figure 3 - Locate DI Water Cartridges

Figure 5 - DI Water Cartridge

Figure 2 - Route the Waste Lines

2. Connect the end of the tubing with the SwageLok fitting to the

GAS

INLET

port, located on

the back of the Analyzer

(Figure 1). Tighten the

fitting until it is finger-

tight, and then tighten an

additional 1/4 turn using a

7/16" open-ended wrench.

3. Connect the other end

of the tubing to the gas

source.

Step 5

Connect the outlet

ports.

The

LIQUID WASTE

outlet and

GAS LIQUID WASTE

outlet are located on the back of the Analyzer

(Figure 2). Both may be routed to the same waste container, however, the

GAS LIQUID WASTE

line MUST be kept free from submerging in any liquid

to prevent liquid from being drawn back into the Analyzer. Routing the lines

through a waste container and lid with a hole allows you to anchor the

GAS

LIQUID WASTE

line higher in the bottle—completely clear from any liquid

waste.

1. Locate the two flexible tubing sections, each 100 cm long, in the

accessories kit.

2. Take one tubing section and connect one end to the

LIQUID WASTE

port. Push the tubing onto the barbed fitting.

3. Route the other end of the tubing to the waste container, placed

within 90 cm of the Analyzer. The end of the tubing should extend to

the bottom of the container.

4. Take the other tubing section and connect one end to the

GAS

LIQUID WASTE

port. Push the tubing onto the barbed fitting.

5. Route the other end of the tubing to the waste container. The end

of the tubing should extend to approximately the top third of the

container.

Note

: To avoid drawing liquid back into the Analyzer, make

sure the vent line is never submerged in the liquid waste inside the

container.

Step 6

Fill the DI water cartridge.

1. Fill the squeeze bottle (provided in the accessories kit) with DI water.

2. Remove the left side panel of the Analyzer and locate the DI water

cartridge. (Figure 3).

3. Lift the spring clip at the top of the DI water cartridge, and then rotate

the cartridge clockwise (as viewed from the top)

to slide it out of the retaining hooks. (Refer to

Figures 4 and 5 as needed for steps 3-8.)

4. Use the John Guest

®

tool to remove the John Guest fittings labeled

“B” and “D” from the barbs on the top of the DI water cartridge.

5. Install fitting B onto barb D.

6. Remove the rubber inlet cover from the top of the DI water

cartridge.

7. Slide the water bottle nozzle into the inlet hole. Fill the cartridge until

water reaches the FULL line.

8. Replace the rubber inlet cover.

Prime the DI Water Pump

1. Connect the power cord to the Analyzer.

2. Turn the Analyzer

On.

The DI water pump will start in 20-30

seconds.

3. Check for large air bubbles in all the tubing that connects to

the DI water cartridge. If large air bubbles are present, tap or

manipulate the tubing to work the air bubbles out.

4. Keep the Analyzer powered

On

for two minutes, and then turn

the Analyzer

Off

.

5. Wait 30 to 60 seconds and then turn the power

On

again. Allow

the DI water pump to circulate water for at least 10 minutes.

6. Check the tubing that leads to the DI water cartridge. Most of

the air originally in the tubing should be replaced with water. If

more than a few small bubbles remain, turn the Analyzer

Off

and

repeat step 5.

7. Turn the Analyzer

Off

.

8. Remove fitting B from barb D.

9. Re-connect fitting B to barb B, and fitting D to barb D.

10. Slide the DI water cartridge into the bracket and rotate it into the

retaining clip until it snaps into place.

11. Inspect the FULL line on the DI water cartridge. If needed, add

more DI water.

12. Replace the left side panel.

Step 7

Install external devices.

1. To communicate with the DataPlus software, connect the Analyzer

to your computer or computer network. Attach one end of the

Ethernet cable to the Ethernet port located on the back of the

Analyzer. Attach the other end of the cable either to an Ethernet

port on your computer or to a connection to your computer network.

2. Install a Printer (Optional).

You can connect a printer to the USB

port located on the back of the Analyzer. Refer to the

Sievers

860 Laboratory TOC Analyzer Operation and Maintenance

Manual

for complete details.

Step 8

Install the DataPlus Software.

Refer to the

Sievers 860 Laboratory TOC Analyzer Operation

and Maintenance Manual

for complete details.

Step 8 A

Run the DataPlus Software installation program on

the computer.

The program installs to a default "DataPlus" location on the C:

drive. We recommend against installing the application in the

computer’s

Programs

folder.

Step 8 B

Power

On

the Analyzer.

Step 8 C

Obtain the IP address.

The Analyzer can connect to the computer through a network

using a dynamic IP address (default) or a static IP address.

Figure 4 - Remove John Guest Fitting

2

DQS 79000-03 EN Rev. A

"D" Fitting

"B" Fitting

Gas/Liquid

Waste Outlet

Port

Liquid Waste

Outlet Port

Gas/Liquid

Waste Line

Liquid

Waste Line