Crankcase pressure can blow hot engine oil out

the

fi ll tube causing severe burns. Always stop

the engine before removing the oil fi ll cap.

If the engine is equipped with the long oil fi ll tube, turn the oil fi ll cap

counterclockwise and lift it up. Wipe the dip stick clean, push it back

into the oil fi ll tube until the cap seats. Withdraw it again to check the

oil level.

CHANGING OIL AND FILTER

Change the oil and fi lter after the fi rst 20 hours of operation. Thereaf-

ter, change oil every 50 hours and the fi lter every 200 hours.

State and federal agencies have determined that

contact with used engine oil can cause cancer or

reproductive toxicity. Take care to limit skin contact

and breathing of vapors as much as possible. Use

rubber gloves and wash exposed skin.

29

30

! WARNING

! WARNING

1 Run the engine until it is warm. Stop the engine and disconnect the

spark plug wires and the battery (negative (-) cable).

Accidental starting of the engine can result in severe

personal injury or death. Always disconnect the spark

plug wires and the battery (negative (-) cable) before

changing

oil.

2 Remove the oil fi ll cap.

Crankcase pressure can blow hot engine oil out the

fi ll opening causing severe burns. Always stop the

engine before removing the oil fi ll cap.

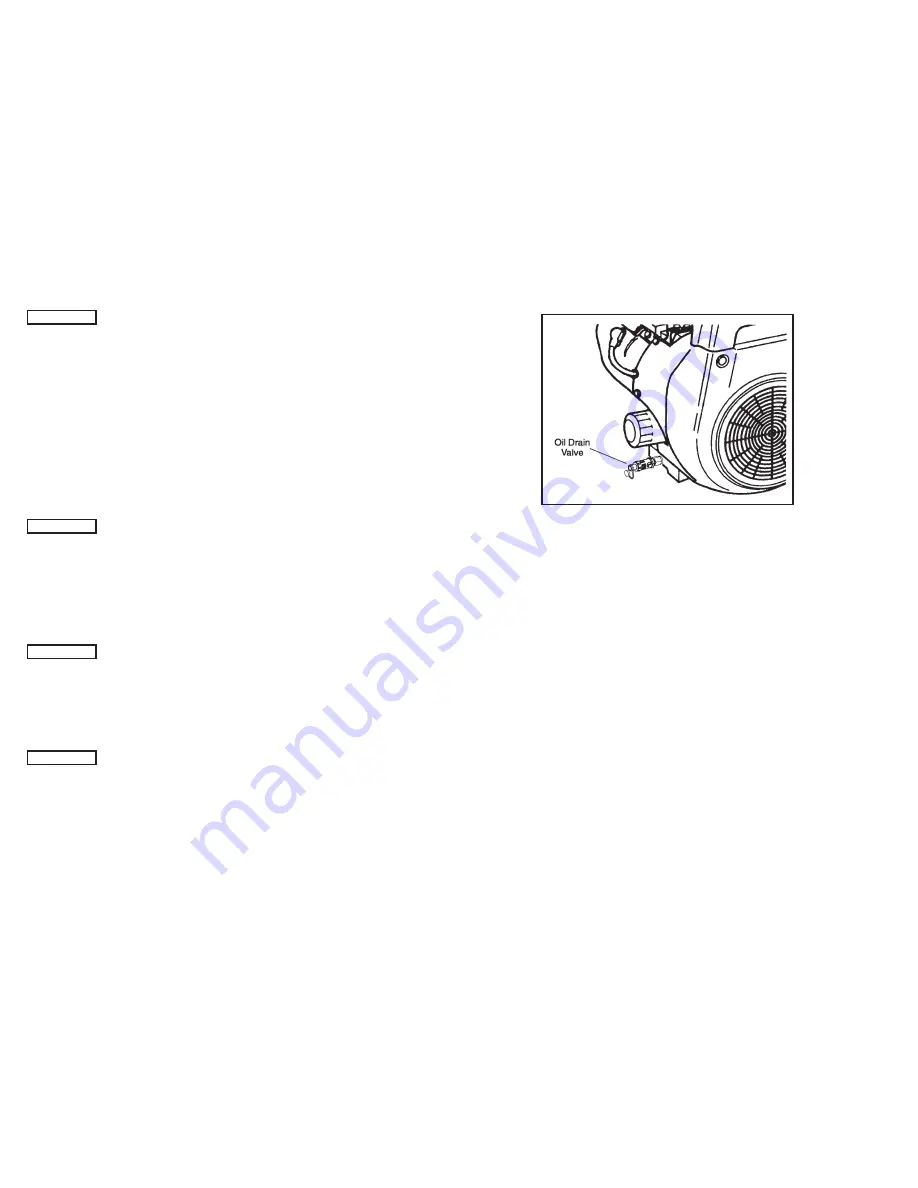

3 To drain oil from crankcase, loosen the drain valve then twist the

outer casing to unlock. The valve is fi tted with an adapter for a drain

tube if desired.

! WARNING

! WARNING

4 Place a pan under the oil drain opening and open the oil drain plug.

Close the plug securely after the oil has drained completely.

5 Spin off the oil fi lter, drain the oil and discard the fi lter according to

local

regulations.

6 Thoroughly wipe off the fi lter mounting surface.

7 Make sure the gasket is in place on the fi lter canister and apply a

thin

fi lm of oil to the gasket.

8 Spin the new fi lter on by hand until the gasket just touches the

mounting surface, then turn it an additional 1/2 to 3/4 turn. Do not

overtighten.

9 Refi ll with class SE (API) of higher having a viscosity grade

appropriate for the expected ambient temperature.

Содержание Subaru Engine EH65

Страница 1: ......

Страница 20: ...40 39...