13 Operating Instructions: DTP05(-Ex)

Troubleshooting

When trying to locate a fault, proceed in the order shown in the table.

NOTE:

Troubleshooting must only be performed by a suitably competent individual as decided

by the company the equipment is intended for use with.

If, after carrying out the following remedial actions, the unit cannot be restored to operation,

contact the manuf

acturer’s technical helpline. In order for customer services to react quickly

and specifically to the fault, the following information is essential:

-

Unit serial number

-

Description of error

-

Unit product name

-

Current location / Company

Consumables

All unit consumables are available from STS. The unit must be fitted with original STS

consumables unless otherwise stated. Any deviation from non-original consumables may

result in injury to personnel or damage to the unit and will invalidate the warranty.

Polycarbonate Guarding Replacement

The polycarbonate guarding should be replaced if damaged, cracked or visibility is

reduced. These are available from STS.

To replace the polycarbonate guard, isolate the unit in a safe area, then proceed as follows:

•

Remove the four rivets located in each corner and remove the old guard.

•

On the new polycarbonate guard, peel back the protective film along all long

edges.

•

Position the new polycarbonate guard so that it fits inside the four tabs and use the

existing holes to drill through with a 6mm drill bit.

•

Reinsert the screw rivets to secure the new polycarbonate guard in place.

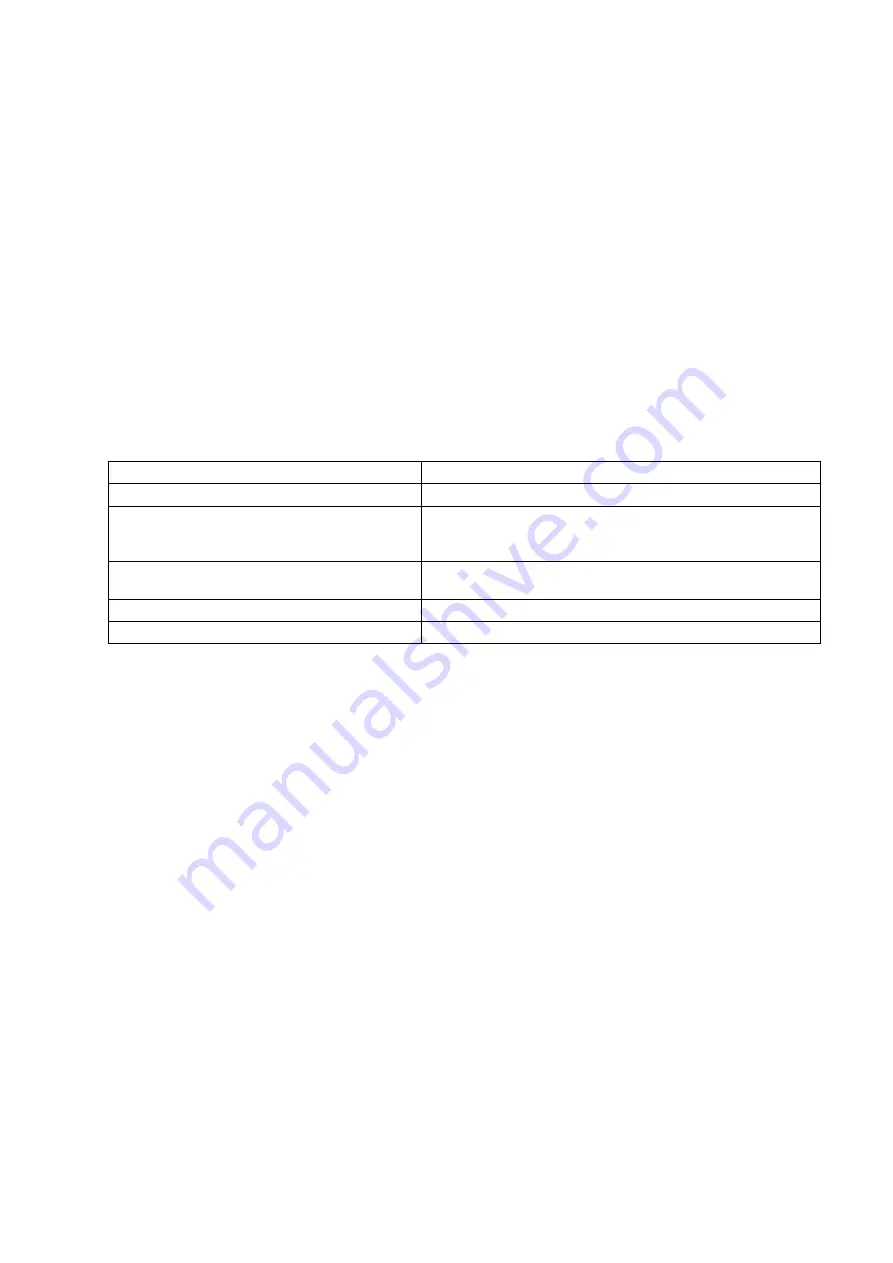

Fault

Reason/Action

Unit does not lift

Unit overloaded, note safe working load of unit

Unit does not lift to full stroke

Pump is short of oil. Ensure rod is at bottom of stroke

and top-up/refill with hydraulic oil. Shell Tellus 22 or

equivalent, half sight glass

Oil leaking from top of hydraulic

cylinder, around chromed rod

Replace hydraulic cylinder seals

Oil leaking from tank filler point

Filler bung damaged or unit over filled with oil

Drum lowering unintentionally

Ensure lowering lever is in the closed position