Theme Plus Issue 2.1 28/06/01

Page 7 of 12

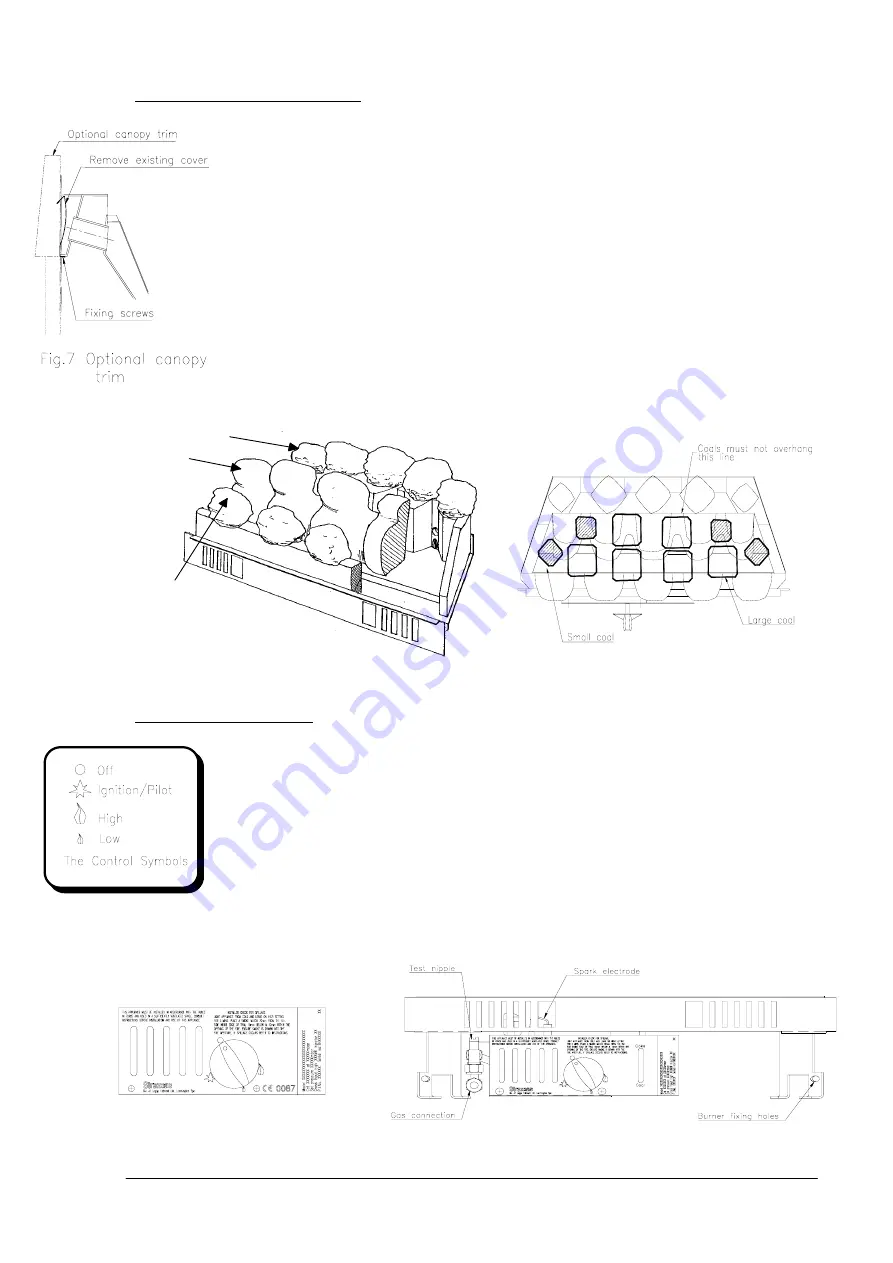

Fig. 8 The data badge plate & test

Final assembly for all types of flue

Following satisfactory installation of the convection box into the opening, proceed as follows:

1. Secure the burner to the convection box using the two screws provided, through the

holes in the front of the legs.

2. Connect the gas supply pipe to the inlet elbow.

3. The ceramic components are fragile and should be handled with care. Refer to Figs.

5 and 6 for positioning of ceramic fibre blocks and coals.

4. Place the chair shaped back ceramic on the burner, pushing it back against the

upturned edge of the burner plate.

5. Place the centre ceramic on the back ceramic pushing it back to sit comfortably

between the tapered sides.

6. Spring forward the slotted front plate and slide the front ceramics down as far as the

stops.

7. Remove the coals from the bag; note that there are 2 sizes supplied with the burner.

Place them on the ceramic blocks in accordance with Fig. 6.

8. If a flat trim or box trim has been supplied, attach it to the fire flange by means of the

magnets. If the optional canopy trim has been supplied, first remove and discard the

existing front cover by undoing the two screws in its bottom edge, then secure the

canopy trim using the same fixings. (See Fig. 7)

Note:

The flat trim and optional canopy trim cannot be used with the spacer frame.

Leak test & pressure test

1. Turn on the main gas supply and check for gas soundness.

2. Remove pressure test screw, and fit pressure gauge to pressure test point.

3. Light the fire (see next section).

4. Turn control knob anti-clockwise to

High

position.

5. When the control knob is in the

High

position, you should have a gas pressure of

19.0mbar ± 1.0mbar when using natural gas and 36.5mbar for propane.

6. Extinguish the fire by turning the control knob clockwise to the

Off

position.

7. Remove the pressure gauge and replace the pressure test screw. Check again for

gas soundness.

8. Fit the front fret by hooking the support lugs at each end over the slotted front plate

on the burner (if using a Straxgas fret), or place an alternative front fret in front of the

burner.

Note:

If a fret from another manufacturer is being used, it must comply with the minimum free

area requirements of Fig. 1.

Fig.6 Placing the loose coals

Back ceram ic

Centre ceram ic

Front ceram ic

Fig.5 Assembling the ceramic blocks

Fig.9 Data badge plate - propane version