5

6 Remove new piston cup(s) from protective cardboard packaging. Set new piston cups

onto retainer plate, these parts will sit flat against each other.

7 Press retainer plate with piston cup into cylinder all the way to the piston. The cylinder

can be rotated to align the screw holes. Apply thread locking compound (Loctite

®

222)

to retainer screws, torque screws to 10-13 inch-pounds.

8 Remove the cylinder o-ring(s) from the bottom of valve plate(s) and install new o-rings.

9 Inspect leaf valves for damage or wear. NOTE: There is one intentionally “bent” leaf

valve per set. If leaf valves need to be replaced, a complete leaf valve plate can be

ordered. The screws holding the leaf valves are susceptible to breaking which makes

individual leaf valve replacement very difficult. Complete valve plate assemblies:

SRC25VP for SRC25 units; SRC50VP for SRC50 units.

10 Check that orientation of the valve plate(s) with ports is correct and place over

cylinders.

11 Remove old and install new head o-rings in the o-ring grooves on top of valve plate.

12 Reinstall head over valve plate(s) checking that orientation with ports is correct. Torque

screws to 50 inch-pounds.

Check that all external accessories such as relief valves

and gauges are not damaged before re-operating product.

TROUBLESHOOTING - ALL UNITS:

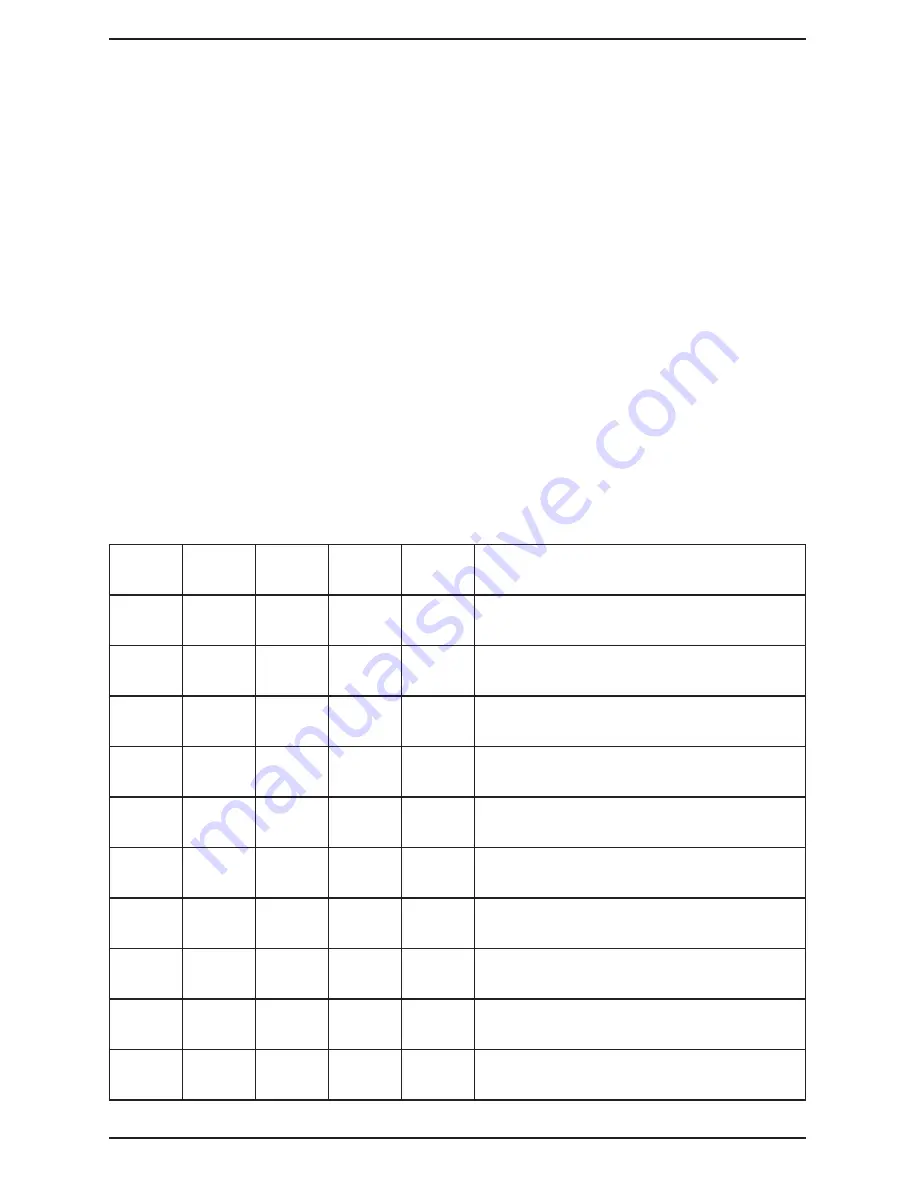

Low High Excess Over Won’t

Pressure Pressure Noise Heating Start

Possible cause and solution

x x x Filter

dirty

Clean or replace

x

x

x

x

Dirty muffler

Clean or replace

x

Dirty valves

Clean or replace

x Bent/damaged

valves

Replace

x

x

Damaged/worn cup

Replace

x

x

Leaky hose

Fix or replace

x

x

Leaky check valve

Fix or replace

x

x

x

Plugged vacuum or pressure line

Fix or replace

x

x

Low voltage

Inspect power supply*

x

Leaky relief valve

Fix or replace

x

x

Motor not wired correctly. Check

wiring diagram and line voltage*

* To troubleshoot low voltage, unit can be tried in an outlet closer to the breaker panel. Voltage drop

in longer electrical runs can cause low voltage.