28/03/19

9

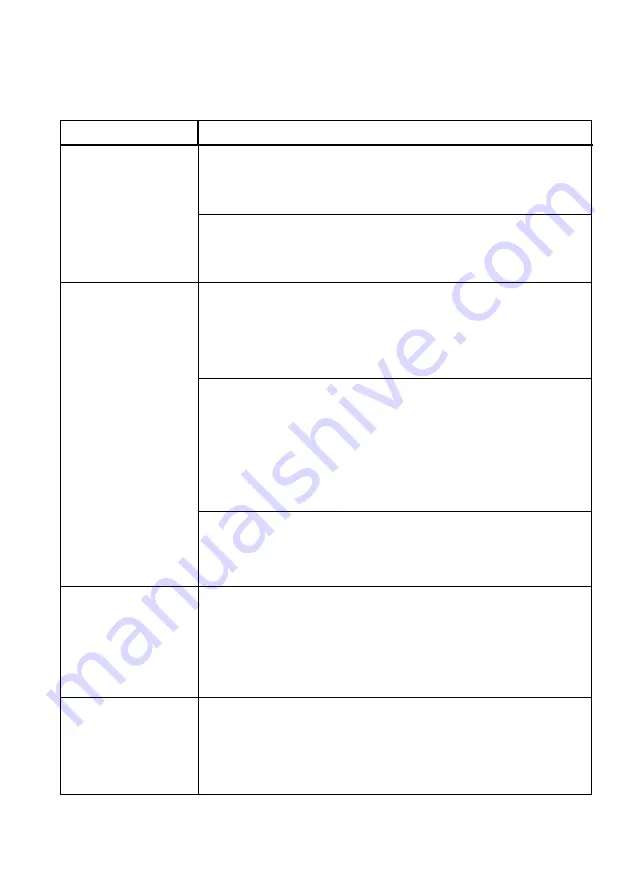

Troubleshooting

SYMPTOM

SOLUTION

The water at the tap

is lukewarm or cold.

1)

Check the thermometer is showing the store temperature is at

or approaching 75

°

C

- 80

C.

2)

If this is not the case, ensure that the boiler is firing, that the

control thermostat is set at 75⁰C and allow sufficient time for the

store to reach working temperature

The thermal store is

at 75°C and the

water at the taps is

still lukewarm or cold

1)

If the store is at or approaching 75°C - 80

C, check that the

Thermostatic Mixing Valve is correctly set. The maximum

temperature of water from the Mixing Valve should be about

55

C.

2)

If the valve is correctly set, check that the flow rate at any outlet

(e.g. bath tap) does not exceed 18 Litres per minute. If the flow

rate is too high then sufficient heat transfer inside may not be

occurring.

Turn the flow through the tap down or fit a suitable flow

restrictor and the temperature will increase.

3)

If Stage 1 and 2 has not resolved the problem a competent

installer should check the mixing valve for blockages within the

internal filter of the mixing valve.

Not enough hot

water and less than

75°C on the

thermometer.

Check the heat sources and their input in (kW) to the store as this will

be lower than the kW output which will result in the store not

producing enough heat for the exchanger to provide heated mains

pressure water.

There is a brownish

tint to the mains

pressure hot water.

This could be a symptom with the heat exchanger coil leaking inside

the thermal store. An installer should have this tested. If this is the

case, pay attention to the Feed & Expansion Tank as the pressure

within the store will increase causing the tank to overflow continually.

Содержание Aquatherm STA140UC

Страница 1: ...0 Technical Manual Manual must be completed by Installer and left with Home Owner...

Страница 16: ...0...

Страница 17: ......

Страница 18: ......

Страница 19: ......