54

Safety instructions:

When working with the cleaning attachment never allow the pressurized nozzles or the water jet to touch

your hands or any other part of your body. When you interrupt or finish work, secure the manual lever on the

high pressure shut off valve against accidental triggering. Never point the cleaning attachment at persons;

note that the residual pressure after switching off the high pressure cleaner could be sufficient to cause

injury. Never reach into the immediate vicinity of the high pressure jet; keep a distance of at least 30 cm. If

you are not using the machine (e.g. during breaks), switch off the High Pressure System Krake and the high

pressure cleaner and release the pressure on the cleaning attachment by removing the manual valve.

CAUTION

Only clean or remove the rotating nozzle inside the cleaning attachment when you have detached the high

pressure hose from the cleaning attachment. Danger of injury!

CAUTION Heat:

When working with hot water, you must wear suitable personal protection (e.g. gloves, goggles, protective

headgear for overhead work). Never clean the machine immediately after finishing work. Remove the suction

basket and allow the machine to cool down for approx. 15 minutes. When working with hot water on scaffolding

make sure that no persons are on the lower levels of the scaffolding to prevent danger of scalding.

CAUTION

The machine should not be used:

−

in areas where there is a risk of explosion and/or to vacuum potentially explosive substances.

−

This applies in particular to areas in which machines must be B1 compliant;

−

to vacuum dusts that are hazardous to health;

−

to vacuum flammable liquids and acids;

−

to vacuum oily or non-conductive liquids;

−

to vacuum ignition sources;

−

without a filter for vacuum cleaning.

CAUTION Electrics:

Never run over, crush or strain the power lead. Check the power lead on the immersion pump and suc-

tion unit regularly for signs of damage. If you detect any damage, do not use the machine. When replacing

power or machine connecting leads, observe the manufacturer's specifications. Couplings on any extension

leads you use must be waterproof. Avoid damaging the pump leads when cleaning the inside of the barrel.

Unplug the mains plug before commencing maintenance work. When cleaning and maintaining machines,

replacing parts, or retooling for a different task, switch the mains switch to the "0" position and unplug the

mains plug. The machine must be operated by trained staff only who are familiar with safety instructions

and have been explicitly instructed to use the machine. Observe the safety and accident prevent rules that

apply on site when using the machine.

The device possesses a voltage range which can pose an electrical hazard to humans and animals. It should

only be unscrewed and / or disassembled by authorised personnel. Similarly, maintenance and repair work

should only be conducted by electrical specialists and authorised service centres. The buyer / user operates the

device at their own risk and under their own responsibility.

If the fuse belonging to the socket used is unknown, the operator of the Power HD Krake must use a safety

device with protective earth conductor monitoring (e.g. PRCD-S article number 60 02 25).

Maintenance / Cleaning:

After use, tip the remaining waste water out of the suction unit barrel. Always flush the barrel with clean water.

Remove stones, paint residue and soiling from the suction inlet on the immersion pump. After cleaning do not

connect the barrel to the suction basket, but allow both parts to dry.

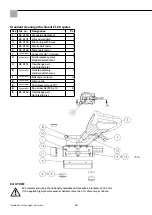

When cleaning, check the machine air filter cartridge below the suction basket for signs of soiling and damage.

To ensure optimum vacuum flow interruption when the filter basket is full, keep the ball in the filter basket,

the filter basket itself and the seal clean.

Flush the cleaning unit thoroughly with clean water after use. Make sure you clean the sealing brushes thoroughly.

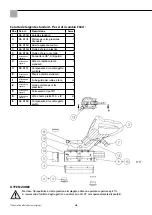

Regularly check that the axle on the dirt blaster is securely seated and tighten it clockwise with the assembly

bolt included in the scope of delivery. To do so, position the assembly bolt in the openings provided for this

purpose on the axis on the inside of the cleaning hood.

Translation of the original instruction