23

C.

When the tension is properly adjusted, the belt

will depress the approximate width of the belt with

the pressure of a fi nger.

D.

If an adjustment is necessary, loosen the four

motor plate retaining nuts, adjust belt tension

then retighten the four nuts.

NOTE

Belt life will be increased if new drive belts are

tightened after two or three weeks of operation.

4.13

CONDENSER CLEANING (AIR-COOLED

MACHINES)

The condenser requires periodic cleaning. To clean the

condenser, refer to the following steps:

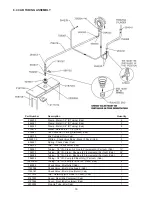

A.

Lift the condenser fi lter off of the machine cover

panel. Visually inspect the condenser fi lter for dirt

(Fig. 4-4).

B.

If the condenser fi lter is dirty, vacuum or brush

it clean. Rinse it with clean water and allow it to

dry before replacing it on the machine.

NOTE

If the condenser is not kept clean, refrigeration ef-

fi ciency will be lost.

4.14 PREVENTATIVE

MAINTENANCE

It is recommended that a preventative maintenance

schedule be followed to keep the machine clean and

operating properly. The following steps are suggested as

a preventative maintenance guide.

The United States Department of Agriculture and the Food

and Drug Administration require that lubricants used in

food zones be certifi ed for this use. Use lubricants only in

accordance with the manufacturer’s instructions.

A. Daily

checks

Check for any unusual noise or condition and

repair immediately.

B. Monthly

checks

1. Check drive belts for wear and tighten belts if

necessary. (Refer to section 4.12)

2. Check the condenser fi lter for dirt. (Refer to

section 4.13).

4.15 EXTENDED

STORAGE

Refer to the following steps for winterizing the machine

or for storing the machine over any long period.

A.

Clean all of the parts that come in contact with

mix thoroughly with warm detergent . Rinse in

clear water and dry all parts. Do not sanitize.

NOTE

Do not let cleaning solution stand in machine barrel

or mix pump during the shutdown period.

B.

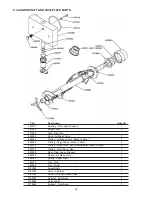

Remove, disassemble, and clean the front door,

auger shaft, and mix pump. Leave disassembled

during the shutdown period.

C.

Place the plastic auger fl ights in a plastic bag with

a moist paper towel. This will prevent the fl ights

from becoming brittle if exposed to dry air over

an extended period (over 30 days).

D.

For water-cooled machines that are left in unheated

buildings, or buildings subject to freezing, the water

must be shut off and disconnected. Disconnect

the fi ttings at the water inlet and the water outlet

lines of the machine. The fi ttings are located at

the rear of the machine. Run the compressor for

2 - 3 minutes to open the water valve. Blow out

all the water, fi rst through the water inlet, then

through the water outlet lines with air or carbon

dioxide. Drain the water supply line coming to

the machine.

E.

Place the Pump OFF/ON switch and the Main

Freezer Power OFF/ON switch in the OFF

position.

F.

Disconnect the machine from the source of the

electrical supply in the building.

Figure 4-4 Removing Condenser Filter