Remark: please not not over lubricating, correct lubricationg is the key factor to keep

the usage life.

3. Judge the friction

Unclean or less lubricating will cause the incresement of friction between running

belt and board, will harm to motor and transducer, the features are as follows:

(1): When off position, it is hard or impossible to move the running belt.

4. Running belt deviation Adjustment:

Both before delivery and after installation, we will make the adjustment on the

running belt .After a period of time running belt running deviation phenomenon

may occur. The causes of this phenomenon are the following several aspects:

(1) Host is not smooth

.

(2) The users’ feet are not run with the center of the area when running

.

5.

Man-made running deviation phenomenon, no-load running two to three minutes

can be back to normal. For running deviation phenomenon which cannot be

automatically move back, should use the special tools (M10) T Allen key in a quarter

of a circle (ninety degrees) adjusted end cover screw and the screw hole

.

6. Specific adjustment method: if run with partial slant to the left, can adjust the

adjusting screw of the left, clockwise or counter-clockwise adjust the adjusting screw

on the right. If the running belt to the right, can adjust to the right of the adjusting

screw clockwise or counter-clockwise adjust the adjusting screw of the left, Suggest

every time make the adjustment of ninety degrees (a quarter circle)

Running belt running deviation does not belong to the warranty scope, mainly by the

user on its own maintenance. Running belt running deviation will be seriously

damaged belt. Must timely discovery, correct in a timely manner.

7.Adjusting methods for running belt: if the running belt in a loosing state, the user

may slipping during running; if the running belt in a tighten state, it may increase the

output power of the motor and transducer. In above two situation, the running belt

should both be adjusted.

(1)Tighten: Using the professional tools-M10 “T”arm inner hex wrench, to adjusting

the adjust screw in the left and right adjusting hole in the back end cover, revolving

the wrench 1/4 circle clockwise each time.(Same range in both side)

(2)Loosing: Using the professional tools-M10 “T”arm inner hex wrench, to adjusting

the adjust screw in the left and right adjusting hole in the back end cover, revolving

the wrench 1/4 circle anticlockwise each time.(Same range in both side)

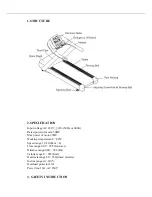

8.Running belt adjusting sketch map

:

Содержание S-900

Страница 1: ...COMMERCIAL TREADMILL S 900 USER MANUAL...