11

VENTING

ANSI now organizes vented

appliances into four categories.

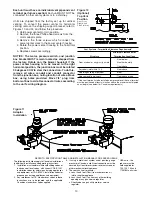

VENTING FOR NATURAL VENTED (CATEGORY

I

) DUCT FURNACES

(Figures 1 and 2)

ALL DUCT FURNACES MUST BE VENTED!

All venting installations shall be in accordance with “Part

7 , Venting of Equipment of the National Fuel Gas Code,

ANSI Z223.1, or applicable provisions of local building

codes.” See below for Canadian Installations. *

CARBON MONOXIDE! Your

venting system must not be blocked by any snow,

snow drifts, or any foreign matter. Inspect your

venting system to ensure adequate ventilation

exists at all times! Failure to heed these warnings

could result in Carbon Monoxide Poisoning

(symptoms include grogginess, lethargy,

inappropriate tiredness, or flu-like symptoms).

This duct furnace is equipped with a

blocked vent (spill) shutoff switch.

Before start up, push reset button on blocked vent

(spill) shutoff switch.

If the venting system becomes blocked or there is

continuous spillage, the vent shutoff switch will shut

off the duct furnace. Before resetting the switch,

check to see if the vent system is blocked; remove

any blockage.

To reset the switch (which is located in the upper

corner of the draft diverter), push the reset button

after the duct furnace has cooled down.

NOTICE: The switch will not reset hot.

Observe the following precautions when venting the unit:

1. Use flue pipe of the same size as the flue

connections on the gas duct furnace (See Table #1).

All heaters should be vented with a UL Listed Type B

vent; a factory built chimney or a lined brick and

mortar chimney that has been constructed in

accordance with the National Building Code.

2. Where two or more gas duct furnaces vent into a

common flue, the cross sectional area of the

common flue must be equal to the largest vent

connection, plus 50% of the area of each additional

vent connection.

3. Provide as long a vertical run of flue at the gas duct

furnace as possible. A minimum of five feet (1.52m)

of vertical flue is required. The top of the vent pipe

should extend at least two feet (.61 m) above the

highest point on the roof. Install a weather cap over

the vent opening.

4. Slope horizontal runs upward from the gas duct

furnace at least 1/4-inch per foot (21mm/m).

Horizontal runs should not exceed 75% of the vertical

height of the vent pipe, or chimney, above the flue

pipe connection, up to a maximum length of 10 feet

(3m). Horizontal portions of the venting system shall

be supported at maximum intervals of four feet

(1.22m) to prevent sagging. See Figure 9.

Category

I

Includes non-condensing

appliances with negative vent

pressure, like the traditional

atmospheric unit heater.

Category

II

Groups condensing appliances

with negative vent pressure.

Category

III

Appliances are non-condensing

and operate with a positive vent

pressure.

Category

IV

Covers condensing appliances

with positive vent pressure.

NOTICE: Category

II

and

IV

do

not apply to equipment specified

within this manual.

Venting Categories

Non

Condensing

Condensing

Negative

Vent

I

II

Pressure

Positive

Vent

III

IV

Pressure

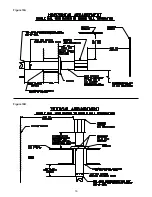

Figure 9

*

The following instructions apply to Canadian

installations in addition to installation and operating

instructions:

1. Installation must conform with local building codes,

or in absence of local codes, with current CGA

B149.1, Installation Codes for Natural Gas Burning

Appliances and Equipment, or CGA B149.2,

Installation Codes for Propane Gas Burning

Appliances and Equipment.

2. Any reference to U.S. standards or codes in these

instructions are to be ignored and the applicable

Canadian standards or codes applied.

Содержание NATURAL INDOOR GAS-FIRED DUCT FURNACE

Страница 14: ...14 Figure 12A Figure 12B...

Страница 15: ...15 Figure 13A Figure 13B...

Страница 34: ...34 NOTES...

Страница 36: ......