16

G

B

by a 16 A fuse. Before you use the machine,

make sure that the mains voltage complies with

the specifications on the rating plate. Long supply

cables, extensions, cable reels etc. cause a drop in

voltage and can impede motor start-up. In the case

of low temperatures below +5°C, motor start-up is

jeopardized as a result of stiffness.

5.4 On/Off switch (ref. 8)

5.4.1

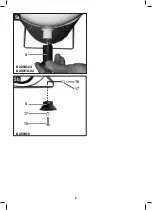

D 200/8/24 - D 200/10/24 (Fig. 2a)

To switch on the equipment set the On/Off switch

(ref. 8) to position

I

.

Move the On/Off switch (ref. 8) to position

O

to

switch off the equipment.

5.4.2

D 200/8/6 (Fig. 2b)

To switch on the compressor, pull out the red knob

(ref. 8)

to position

I

.

To switch off the compressor, press the red knob

(ref. 8) in again

to position

O

.

5.5 Adjusting the pressure

● You can adjust the pressure on the pressure

gauge (ref. 6) using the pressure regulator (ref.

7).

● The set pressure can be taken from the quicklock

coupling (ref. 5).

5.6 Setting the pressure switch

The pressure switch is set at the factory.

5.6.1

D 200/8/6 - D 200/8/24

Switch-on pressure 6 bar

Switch-off pressure 8 bar

5.6.2

D 200/10/24

Switch-on pressure 8 bar

Switch-off pressure 10 bar

6. CLEANING AND MAINTENANCE

Warning!

Pull the power plug before doing any cleaning

and maintenance work on the appliance.

Warning!

Wait until the compressor has completely cooled

down. Risk of burns!

Warning!

Always depressurize the tank before carrying

out any cleaning and maintenance work.

6.1 Cleaning

● Keep the safety devices free of dirt and dust

as far as possible. Wipe the equipment with a

clean cloth or blow it with compressed air at low

pressure.

● We recommend that you clean the appliance

immediately after you use it.

● Clean the appliance regularly with a damp cloth

and some soft soap. Do not use cleaning agents

or solvents; these may be aggressive to the

plastic parts in the appliance. Ensure that no

water can get into the interior of the appliance.

● You must disconnect the hose and any spraying

tools from the compressor before cleaning. Do

not clean the compressor with water, solvents or

the like.

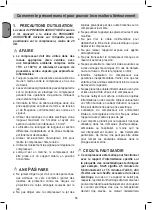

6.2 Condensation water

The condensation water must be drained off each

day by opening the drain valve (ref. 11) (on the floor

of the pressure vessel).

Warning!

The condensation water from the pressure

vessel will contain residual oil. Dispose of the

condensation water in an environmentally

MAINTENANCE RESUMPTIVE TABLE

FUNCTION

AFTER THE FIRST

100 HOURS

EVERY 100 HOURS

Cleaning of intake filter and/or

substitution of filtering element

●

●

Draining tank condensate

Periodically and at the end of work

Содержание D 200/10/24

Страница 6: ...6 1a 1b 9 2 5 7 1 1 11 9 4 2 11 10 5 7 D 200 8 24 D 200 10 24 D 200 8 6 6 12 4 6 3...

Страница 8: ...8 5a 5b 4 15 17 4 D 200 8 24 D 200 10 24 D 200 8 6 17 16...

Страница 58: ...58 R U S 1 4 m 20 dB 5 C 40 C 4 5 1 5 2...

Страница 59: ...59 R U S 2 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 3 4 5 C 40 C S3 25 2 5 7 5 5 4 D 200 8 6...

Страница 61: ...61 R U S 6 2 11 6 3 10 6 4 7 100 100...

Страница 62: ...62 R U S 8...