12

• The electrical motors have to be built in accordance with EN 60034-1.

• Enclosures of electrical motors and control systems on the pump unit shall as a minimum

have protection in accordance with EN 60529 IP22. But in determining the degree of protection

of enclosures of electrical motors and control systems on the pump unit the operating and

environmental conditions must be taken into consideration.

If there is possibility of the pump operating with its delivery valve is closed completely

(that is, at zero flow rate) or almost closed (that is, at very little rate), a by-pass valve

should be used on the outlet flange of the pump or on the delivery pipe just after the

pump, but in advance of the control valve should be used. If such a valve is not used and

the pump operates for a long time, almost all power given by the engine converts to

thermal energy and transfers to the delivered liquid. This situation may cause overheating

and, consequently, cause significant failures.

• Electirical connection should be done by a qualified electrician. Current national regulation and

motor manufacturer’s instructions must be observed.

• Take all safety precautions listed in “Safety instructions”. Disconnect all power supplies prior to

doing any work.

• The supply cable must be laid in such a way that it never touches the pipework, pump and motor

casing.

• Check voltage, phase and frequency on motor nameplate with the mains.

• The electric motor must be protected against overloading by means of circuit breakers and/or fuses.

Circuit breakers and fuses must be selected in accordance with full load amperage of the motor

appearing on the motor rating plate.

• It is recommended to use PTC (passive thermal control) on motor, bu this is optional depending on

customer requirement. In case of using PTC, these should be connected via corresponding terminals

in the terminal box and the PTC should be connected to the thermal trip mechanism.

• Prior to connection the electrical wiring rotate the pump shaft by hand to make sure rotor rotates

easily.

• Connect the electrical wiring in accordance with local electrical codes and make sure to ground the

motor.

• The connection diagram can be found in the terminal box of the motor or in the instruction manual.

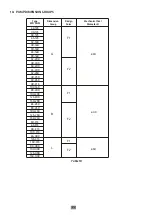

• The mains connection on the terminal box depends on the nominal power of the motor, the power

supply and the type of connection. The necessary coneccton of the bridges in the terminal box is

shown in the following (

Table 2 ve Figure 7a, 7b, 7c)

.

4.6- Electrical Connections

4.5- Minimum Flow

ATTENTION

ATTENTION

Содержание ECO SNM 100-160

Страница 1: ...ECO SNM Instruction for Operation and Maintenance Single Stage Norm Centrifugal Pumps ...

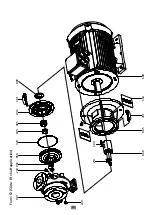

Страница 28: ...24 301 088 001 230 065 050 420 049 405 043 230 060 005 301 550 600 210 380 Form F2 Slide fit shaft application ...

Страница 29: ...25 600 085 340 060 320 Rigid Coupling Application For motor shaft diameters of Ø60 mm or bigger ...