11

Isolation Valve

Vent Valve

Figure 3

4.4.4- Auxiliary pipe connections and accessories

• Depending on the application auxiliary pipe connections (for

cooling, sealing and flushing of seal, drainage etc. necessary for

the pumping system) and/or accessories to check operating

conditions (pressure gauges, temperature gauges etc.) may be

made up and lail.

• Pressure and vacuum gauges must be properly anchored and

connected at the measuring points located on the pump flanges

by means of or on the pipes close to the flanges approximately

8 mm diameter tubing with pig tail configuration to lessen

pressure fluctuation. For safety purposes isolating and vent valves

should be fitted before the gauges

(Figure 3)

.

• Every pump is fitted with connections on the pump casing to

drain the pump

(Figure 4)

. If required the pump drain can be piped

to a suitable reservoir. The pump draining piping must be fitted

with an isolating valve and both must be suitable for the

maximum operating pressure of the pump.

• Cooling, sealing and flushing of seal piping must be connected

only to the designated connections located on the pump

(Figure 5,6).

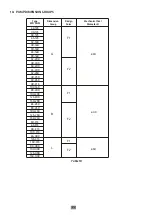

d1 :

Pressure gauge (discharge)

d2 :

Pressure gauge (suction)

d3 :

Filling or vent

d4 :

Drain

Figure 4

Figure 6

Figure 5

d3

d1

d4

d2

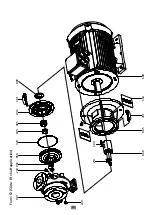

F1

F1 Q1

Q2

F1 :

Seal flushing liquid inlet from external source

Q1:

Mechanical seal quench liquid inlet from external source.

Q2:

Mechanical seal quench liquid outlet.

Содержание ECO SNM 100-160

Страница 1: ...ECO SNM Instruction for Operation and Maintenance Single Stage Norm Centrifugal Pumps ...

Страница 28: ...24 301 088 001 230 065 050 420 049 405 043 230 060 005 301 550 600 210 380 Form F2 Slide fit shaft application ...

Страница 29: ...25 600 085 340 060 320 Rigid Coupling Application For motor shaft diameters of Ø60 mm or bigger ...