6

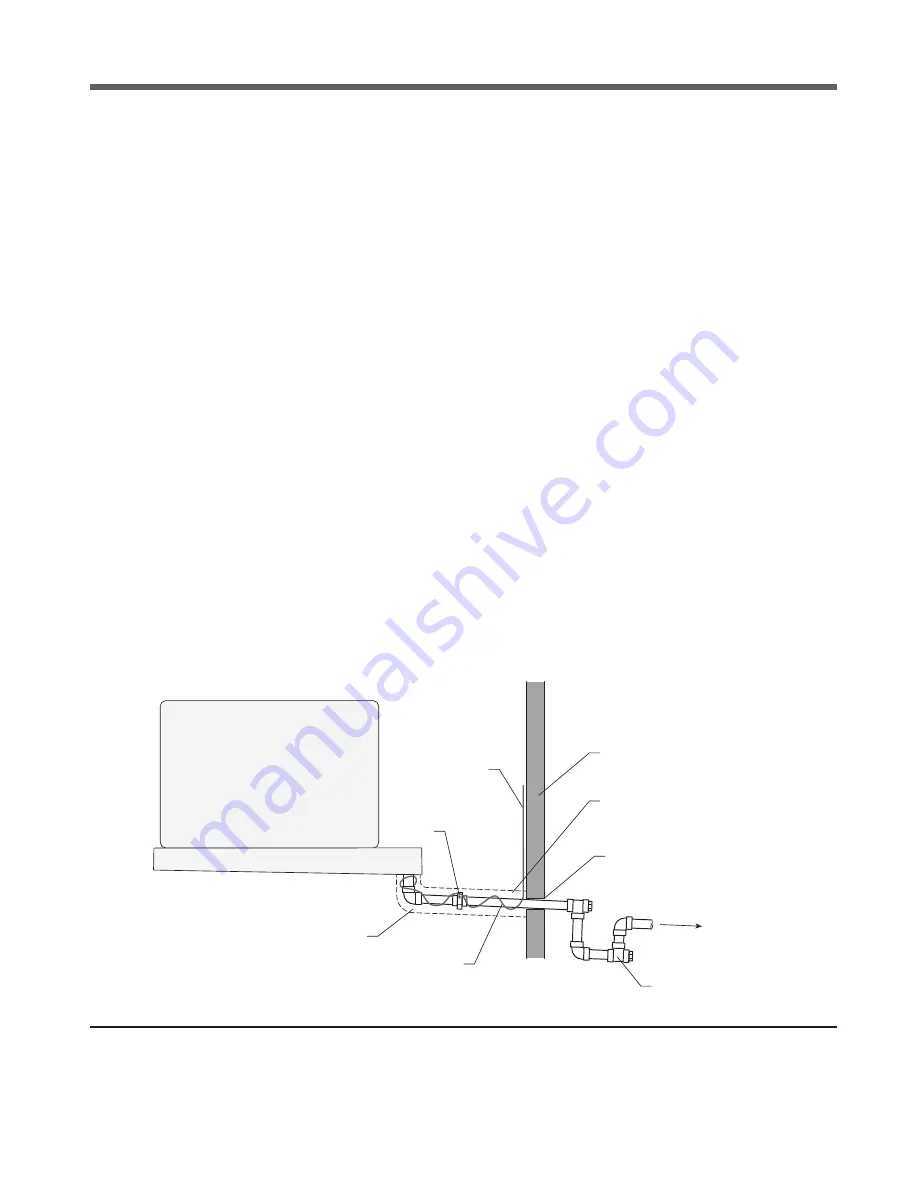

FIGURE 2

Drain Line

installation

5 REFRIGERANT WARNING

The use of any refrigerant can be dangerous under certain

conditions. Where people or product can be exposed to hazardous

conditions, daily inspections should be made for the detection

of any defect or malfunction that could cause the escape of the

refrigerant and cause harm. In the case of halocarbon refrigerants,

electronic detection devices are available for sensing the presence

of such refrigerants in the atmosphere.

Ammonia

is a “self-alarming” gas with its strong odor but detection

devices are strongly recommended. People and product are a

concern based on the concentration levels (ppm) of ammonia

along with OSHA and EPA regulations. An ammonia gas detection

device connected to an external alarm system to warn that a

leak is occurring is recommended. Refer to local codes and Fire

Department for additional local regulations.

Only experienced, qualified personnel should install, operate, and

maintain detection and alarm equipment.

6 PIPING INSTALLATION

6.1 DRAIN LINE

The drain line should be connected to both drain pans, and should

be as short and as steeply pitched as possible with a minimum

of ¼” drop per running foot. The drain line should be the same

size, or one size larger then drain pan connections. A drain line

trap should be installed to prevent warm moist air from migrating

through the drain line. The trap should be located in the warmest

and/or lowest section of the piping to avoid freezing and provide

sufficient liquid head for flow through the trap. If the temperature

surrounding the drain line is below freezing (32°F) it must be

wrapped with a drain line heater and insulation. Be sure to also wrap

the drain pan coupling. The drain line heater should be energized

continuously, but to avoid the possibility of overheating heat tape

manufacturers recommend a thermostat be installed. Be sure to

follow the manufacturer’s recommendations. The drain line trap

should be outside of the freezing space. See Figure 2.

A union at the drain pan connection is recommended for future

servicing. The union should be located outside the edge of the

drain pan so that when the pan is lowered for cleaning or repair the

drain line run is not in the way. Use two wrenches when tightening

to prevent the drain fitting from twisting and damaging the drain

pan. See Figure 3.

Long runs of drain line, i.e. more than a few feet, should be supported

by hangers to avoid damage to the drain pan. For cleaning and

inspecting the drain, tees with plugs are recommended instead

of elbows.

Insulated

Wall

Evaporator

Drain pan

Heating cable

power line

Drain line wrapped

with insulating material

Thermostatically controlled

heating cable

Union

Vapor seal the

pipe penetration

4" to 6"

drain trap

with access

Condensate

drain line

Slope drain pipe down

and away from evaporator

(1/4" per foot of pipe)