Sheet No.

Issue Date: Rev. E Jan. 25, 2006

© 2004 SPX Corporation

Parts List & Operating Instructions

Form No. 528220

WARNING: To prevent personal injury and damage to equipment,

•

Study, understand, and follow all instructions, including the ANSI B30.1 safety code for jacks.

•

If the operator cannot read these instructions, operating instructions and safety precautions

must be read and discussed in the operator’s native language.

•

Wear eye protection that meets ANSI Z87.1 and OSHA standards.

•

Inspect the jack before each use; do not use the jack if it’s damaged, altered, or in poor

condition.

•

Before using the jack for the first time, perform the setup procedure outlined below to

correctly set the lowering and raising speed of the jack.

•

Use only on a hard, level surface.

•

A load must never exceed the rated jack capacity.

•

Lower the load completely before moving the jack. Slowly and carefully move the jack around

corners because the load could tip.

3 of 4

Safety Precautions

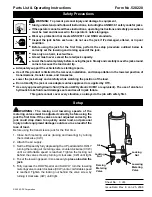

Setup

Locking

Nut

Lowering

Metering

Valve

Air

Locking

Nut

Raising

Metering

Valve

WARNING: The raising and lowering speeds of the

metering valves must be adjusted correctly before using the

jack the first time. If the valves are not adjusted correctly, the

jack could drop down too quickly under load, and personal

injury and/or equipment damage could occur as a result of the

loss of load.

Before using the transmission jack for the first time:

1. Close both metering valves (raising and lowering) by turning

them clockwise (CW).

2. Attach the air supply.

3. Set the lift speed by fully depressing the UP pedal and SLOWLY

turning the raising air metering valve counterclockwise (CCW)

until a comfortable speed is reached. Tighten the locking nut

behind the valve screw by turning it clockwise (CW) until tight.

4. To set the lowering speed, it is necessary to place a load on the

jack.

5. Fully depress the DOWN pedal and SLOWLY turn the lowering

metering valve counterclockwise (CCW) until a comfortable speed

is reached. Tighten the locking nut behind the valve screw by

turning it clockwise (CW) until tight.

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

•

Adequately support the vehicle before starting repairs.

•

Use of this product is limited to the removal, installation, and transportation in the lowered position of

transmissions, transfer cases, and transaxles.

•

Lower the jack slowly and carefully while watching the position of the load.

•

Do not modify the jack or use adapters unless approved or supplied by OTC.

•

Use only approved hydraulic fluid (Chevron AW Hydraulic Oil MV or equivalent). The use of alcohol or

hydraulic brake fluid could damage seals and result in jack failure.

This guide cannot cover every situation, so always do the job with safety first.

l

l

l

l

l