Parts List & Operating Instructions

1. Assemble the swivel casters on the jack legs using lock washers

and nuts provided.

2. Assemble the legs (with casters) to the jack’s base, and slightly

secure with the Allen socket bolts and lock washers provided.

3. Position the jack (with legs) on a hard level surface. Tighten the

Allen socket bolts while all four casters are contacting the floor,

and the jack appears vertical to the floor.

4. Assemble the handle by screwing it into the handle socket on the

top base and tightening it with your hand.

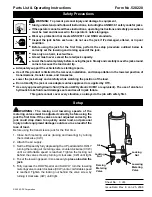

5. Saddle assembly: Loosen the screw from outside the saddle

adapter. Mount the saddle adapter onto the top of the piston rod.

Once mounted, tighten the screw and secure the entire saddle

assembly.

6. Use the tilt adjusting knob to adjust the saddle angle to a relatively

horizontal position.

7. Attach the two corner support brackets onto the saddle board, and

fasten with the hex bolts and nuts.

8. Locate the corner support bracket in the chain pack. Assemble

the corner support bracket on the saddle side frame, and secure

with the nuts mounted. Assemble chains and chain hardware to

the corner support bracket.

9. Chains and chain hardware are provided to secure a transmission,

transfer box, or differential to the saddle assembly according to the

different shape of each housing. When in use, both ends of the

chain should be anchored to the bracket.

Assembly

WARNING: DO NOT RAISE, LOWER, OR TRANSPORT A TRANSMISSION UNLESS IT IS SECURED

BY THE RESTRAINT SYSTEM. IT IS YOUR RESPONSIBILITY TO ADJUST THE RESTRAINT SYSTEM TO

A SUITABLE POSITION. OTC IS NOT SUBJECT TO ANY RESPONSIBILITY FOR INCORRECT SETUPS

OF THE RESTRAINT SYSTEM THAT MAY CAUSE PERSONAL INJURY AND/OR PROPERTY DAMAGE.

Tilt

Screw

Saddle

Foot

Pedal

Caster

Form No. 528220, Back of Sheet 2 of 4