24

maintenance

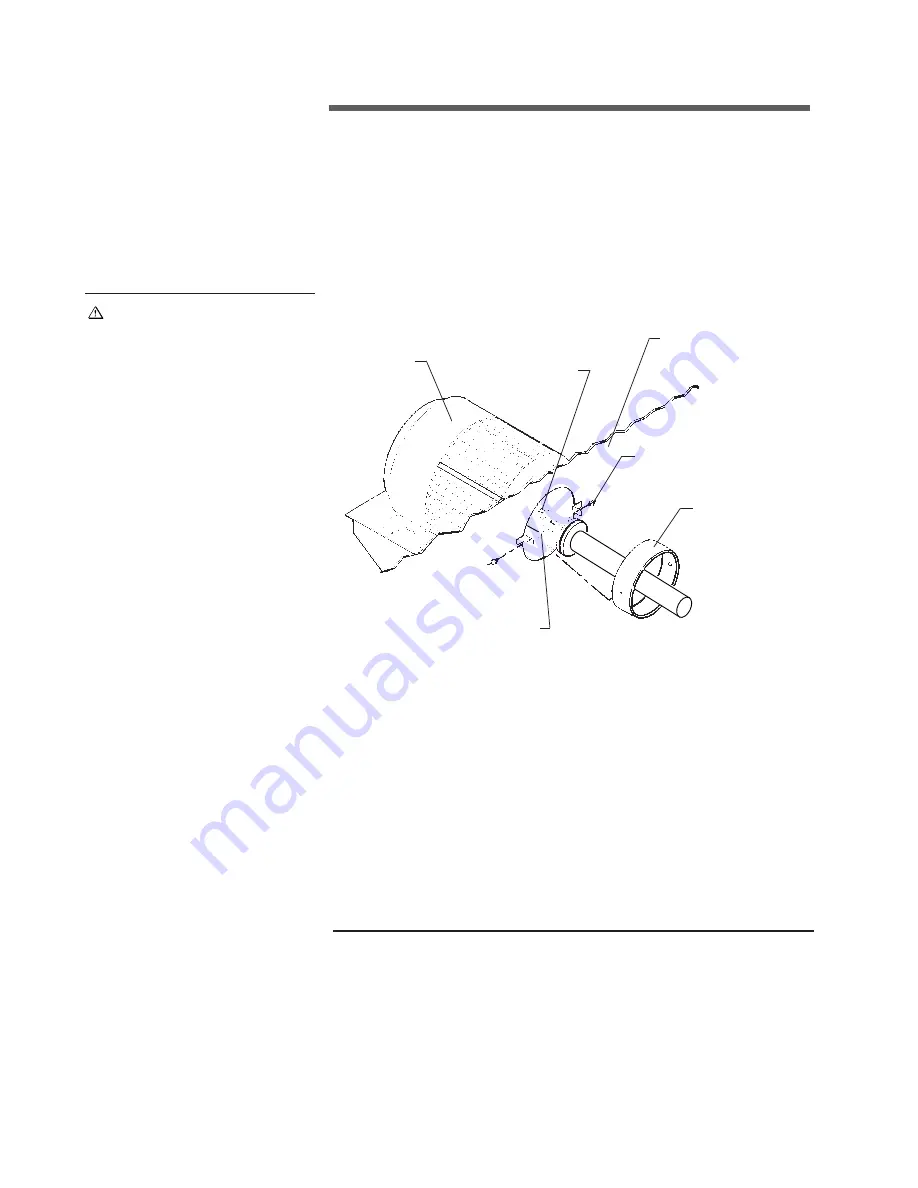

Motor Lubrication Instructions:

Motor located outside plenum option. Not required for motors with sealed

bearings.

Open and lock out disconnect switch to make certain motor cannot

be started.

1. Remove guard as shown. Opposite end motor bearing is accessible from

outside the tower.

2. Remove grease fill and relief plugs at both shaft extension end and opposite

end bearings and remove hardened grease, using clean wire.

3. Insert grease fittings in grease fill openings and add grease until grease is

forced out through relief openings.

4. Replace fill plugs and operate mechanical equipment 30 minutes to one

hour to purge excess grease at grease relief opening.

5. Reinstall grease relief plugs and reinstall guard.

6. Resume normal tower operation.

Seasonal Shutdown Instructions

When the system is to be shut down for an extended period of time, it is

recommended that the entire system (cooling tower, system piping, heat

exchangers, etc.) be drained. Leave the basin drains open.

During shutdown, follow recommendations in the

Cooling Tower Inspec-

tion and Maintenance

section of this manual before attempting repairs.

Pay particular attention to mechanical equipment supports and coupling (or

drive shafts).

Warning

Motor

Guard

Steel Side Casing

Attachment Screw

Grease Relief Plug

Grease Fill Plug

Содержание Marley NCWD

Страница 31: ......