OPERATION

SPT17/20X 86037300 01/24/07

3-3

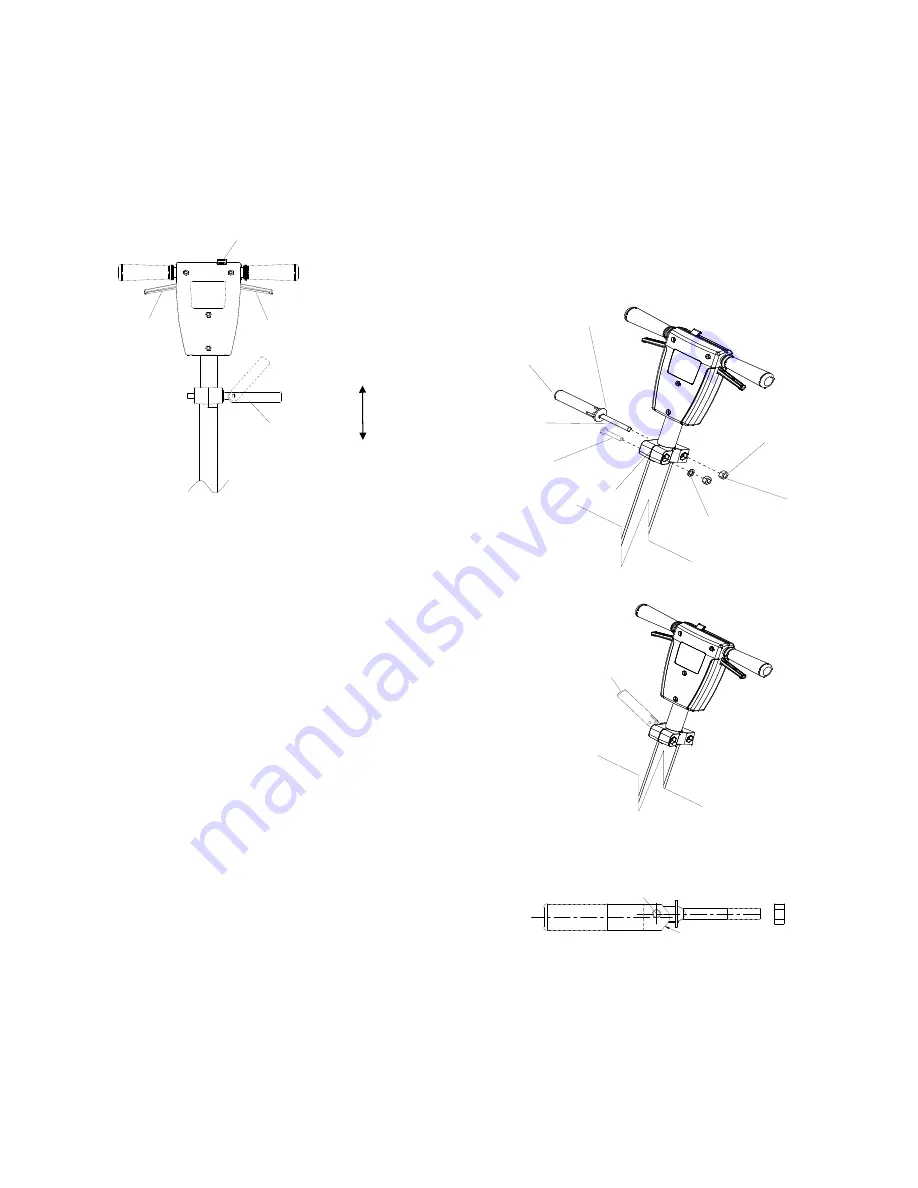

CONTROLS

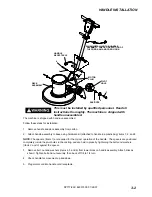

1. Safety Lock –

Prevents unintended operation of

the machine.

2. Switch Levers –

Turns machine on/off.

3. Adjustment

Handle

–

Allows the handle to be

adjusted to a comfortable operating position.

The handle adjust bar (86215130 - PRV

NO.

14344

) for the polishers are individually

preset at the factory for optimum locking

efficiency and minimum effort of engaging. It

should not be necessary to adjust the handle

adjust bar unless the relationship of the handle

adjust bar nut (86136360 - PRV NO.

57275

) or

fixed clamp bolt (86136700 – PRV NO.

70692

)

and their corresponding nuts (86136360 –

PRV NO.

57275

) and washer (86010720 –

PRV NO.

87086

) have been disturbed. The

handle can be positioned to be locked with the

handle adjust bar pointing either up or down.

In order to change the position the handle and

bolt must be removed and rotated 180

degrees. It is incorrect to make it lock opposite

from the way it was assembled by applying

more force to the nut. From the factory the

locking is in the up position when the machine

handle is locked. The pivot pin (86222560 –

PRV NO.

66334

) on the handle adjust bar is

off center, in relationship of the screw to the

axis of the (see drawing). To adjust handle

adjust bar, tighten nut on handle while in the

locked position. The handle is locked when the

screw is to the outside of the machine and the

flat on the opposite side of the handle is flush

to the bracket.

1. To adjust handle lock, tighten nut on handle while

in the locked position. Optimum locking force and

ease of locking is accomplished when the locking

lever nut is set to a torque of 30 to 50 inch pounds

in the locked position.

2. Gap between clamp halves at the front should be

to the gap in rear when the handle adjust bar is

adjusted properly and in the locked position (gap

approximately 1/16").

2

2

1

3

LOCK

UNLOCK

LOCKING SIDE FLAT

86222560

PRV NO. 66334

PIVOT PIN C

L

HANDLE C

L

S H O W N H A N D L E IS

IN L O C K P O S IT IO N

P R V N O . 1 4 3 4 4

P R V N O . 6 7 4 3 0

P R V N O . 8 7 2 0 2

8 6 1 3 6 7 0 0

2

1

8 6 2 1 5 1 3 0

8 6 2 2 5 7 1 0

P R V N O . 7 0 6 9 2

8 6 2 2 3 5 5 0

P R V N O . 5 7 2 7 5

8 6 1 3 6 3 6 0 (2 )

8 6 0 1 0 7 2 0

P R V N O . 8 7 0 8 6

Содержание SPT17 10090370

Страница 12: ...SPT17 20X 86037300 01 24 07 3 5 THIS PAGE LEFT BLANK INTENTIONALLY...

Страница 15: ...WIRING DIAGRAM NOTES SPT17 20X 86037300 01 24 07 4 3 NOTES...

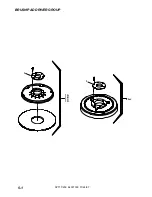

Страница 16: ...BRUSH PAD DRIVER GROUP SPT17 20X 86037300 01 24 07 1A 1B 1D 1C 3 3 2A J 5 1...

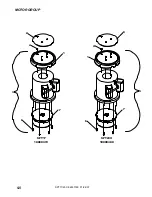

Страница 20: ...MOTOR GROUP SPT17 20X 86037300 01 24 07 1 7 6 1 2 4 3 6 7 4 8 5 SPT20X 10090380 SPT17 10090370 5 5...

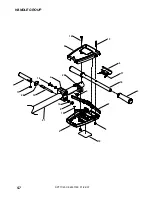

Страница 22: ...HANDLE GROUP SPT17 20X 86037300 01 24 07 1 11 20 12 2 5 14 13 6 17 18 3 7 19 9 15 8 4 10 21 22 16 9 5 7...

Страница 24: ...WIRING GROUP SPT17 20X 86037300 01 24 07 5 9 8 4 6 2 11 6 11 3 1 10 9 7 5 12 PRIOR TO SN...

Страница 27: ...NOTES SPT17 20X 86037300 01 24 07 5 12...