2

1.3

Lighting

Ensure adequate lighting, particularly where detailed or intricate work is

required.

1.4

Hazardous liquids or gases in the pipeline

Consider what is in the pipeline or what may have been in the pipeline

at some previous time. Consider: flammable materials, substances

hazardous to health, extremes of temperature.

1.5

Hazardous environment around the product

Consider: explosion risk areas, lack of oxygen (e.g. tanks, pits), dan-

gerous gases, extremes of temperature, hot surfaces, fire hazard (e.g.

during welding), excessive noise, moving machinery.

1.6

The system

Consider the effect on the complete system of the work proposed. Will

any proposed action (e.g. closing isolation valves, electrical isolation)

put any other part of the system or any personnel at risk?

Dangers might include isolation of vents or protective devices or the

rendering ineffective of controls or alarms. Ensure isolation valves are

turned on and off in a gradual way to avoid system shocks.

1.7

Pressure systems

Ensure that any pressure is isolated and safely vented to atmospheric

pressure. Consider double isolation (double block and bleed) and the

locking or labeling of closed valves. Do not assume that the system has

depressurized even when the pressure gauge indicates zero.

1.8

Temperature

To avoid burns, it is essential that cooling water is flowing before open-

ing the sample inlet valve. Always close the sample inlet valve before

turning off the cooling water.

1.9

Tools and consumables

Before starting work ensure that you have suitable tools and/or con-

sumables available. Use only genuine Spirax Sarco replacement parts.

1.10

Protective clothing

Consider whether you and/or others in the vicinity require any protec-

tive clothing to protect against the hazards of, for example, chemicals,

high/low temperature, radiation, noise, falling objects, and dangers to

eyes and face.

1.11

Permits to work

All work must be carried out or be supervised by a suitably

competent person.

Installation and operating personnel should be trained in the correct

use of the product according to the Installation and Maintenance

Instructions.

Where a formal ‘permit to work’ system is in force it must be complied

with. Where there is no such system, it is recommended that a respon-

sible person should know what work is going on and, where necessary,

arrange to have an assistant whose primary responsibility is safety.

Post ‘warning notices’ if necessary.

1.12

Handling

Manual handling of large and/or heavy products may present a risk of

injury. Lifting, pushing, pulling, carrying or supporting a load by bodily

force can cause injury particularly to the back. You are advised to

assess the risks taking into account the task, the individual, the load

and the working environment and use the appropriate handling method

depending on the circumstances of the work being done.

1.13 Residual

hazards

In normal use the external surface of the product may be very hot. If

used at the maximum permitted operating conditions the surface tem-

perature of some products may reach temperatures of 662°F (350°C ).

Many products are not self-draining. Take due care when dismantling

or removing the product from an installation (refer to ‘Maintenance

instructions’).

1.14

Freezing

Provision must be made to protect products which are not self-draining

against frost damage in environments where they may be exposed to

temperatures below freezing point.

1.15

Disposal

Unless otherwise stated in the Installation and Maintenance

Instructions, this product is recyclable and no ecological hazard is

anticipated with its disposal providing due care is taken.

1.16

Returning products

Customers and stockists are reminded that under EC Health, Safety

and Environment Law, when returning products to Spirax Sarco they

must provide information on any hazards and the precautions to be

taken due to contamination residues or mechanical damage which may

present a health, safety or environmental risk. This information must be

provided in writing including Health and Safety data sheets relating to

any substances identified as hazardous or potentially hazardous.

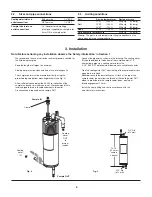

2.1 Description

The Spirax Sarco SSC20 sanitary sample cooler has been specifically

designed for taking high quality chemical, conductivity and microbio-

logical samples quickly and safely from clean/pure steam, water for

injection (WFI) and other high purity media systems.

The unit consists of high quality 316L stainless steel components and

utilizes a counter current flow to maximize cooler efficiency, resulting in

a compact, space saving design.

All sample contact surfaces are compliant to current ASME BPE.

Surface finish of better than 0.5 µ-m Ra (20 µ-in Ra).

The unit is provided with an integral pre drilled mounting bracket to

allow simple installation at point of use.

2. General product information

Sample IN

Sample OUT

Clamp