MAINTENANCE

See Maintenance Schedule on Page 21.

Disconnect, tag and lock out power source then release all pressure from the

system before attempting to install, service, relocate or perform any maintenance.

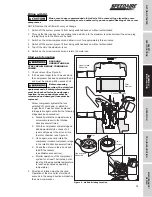

In order to maintain efficient operation of the compressor system,

check the oil level before each use. The ASME safety valve should

also be checked daily (see Figure 10). Pull ring on safety valve.

Once pressure has been relieved, safety valve will close. This

valve automatically releases air if the tank pressure exceeds the

preset maximum. If air leaks after the ring has been released, or

the valve is stuck and cannot be actuated by the ring, the ASME

safety valve must be replaced.

Do not tamper with the ASME safety

valve.

Tank

Never attempt to repair or modify a tank! Welding, drilling or any other

modification will weaken the tank resulting in damage from rupture or explosion.

Always replace worn, cracked or damaged tanks.

Drain liquid from tank daily.

The tank should be carefully inspected at a minimum of once a year. Look for cracks forming near the welds. If a

crack is detected, remove pressure from tank immediately and replace.

Oil Change

RISK OF INJURY! The unit consists of rotating and pressurized components. Do

not attempt to change oil until the unit has completely stopped and been fully

depressurized.

Disconnect, tag and lock out power source then release all pressure from the

system before attempting to install, service, relocate or perform any maintenance.

RISK OF BURNS! The unit parts, oil, and screw plug can be hotter than 175° F

(80° C)! Wear personal safety equipment!

1. Switch off the system, prevent it

from being switched back on without

authorization, and bring it into a horizontal

position.

2. Depressurize the tank and system

completely.

3. Unscrew the oil plug of the filler neck by

hand.

4. Carefully unscrew the oil drain cap and

catch the used oil in a suitable container.

Dispose of the used

oil, oil-contaminated

container, and cloths in accordance with

local regulations.

5. Clean the oil drain pipe to remove any

remaining oil. Tighten drain cap to original closed position.

18

MAINTENANCE /

REP

AIR

TROUBLESHOOTING

OPERA

TION

ASSEMBL

Y /

INST

ALLA

TION

SAFETY

/

SPECIFICA

TIONS

GETTING ST

ARTED

Figure 10 - ASME Safety Valve

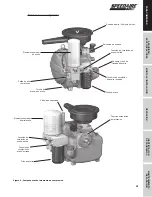

Figure 11 - Oil Drain

Oil Drain Pipe and Cap