Speedaire

®

3/8" Air Composite Drill

10D240

Workplace Hazards (continued)

This tool is not intended for use in

explosive atmospheres and is not

insulated for contact with electric

power sources.

Some examples of these

chemicals are:

General Safety information

(continued)

Installation

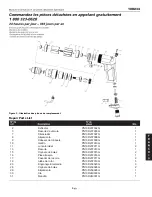

Figure 2 - Air Diagram

Figure 3

Designed to operate on 90 PSI, lower

pressure (below 90 PSI) will reduce

performance of the tool while higher

air pressure (over 90 PSI) raises the

performance of the tool beyond its

rated capacity and could cause serious

damage to tool and user.

Always use clean dry air. Excessive

moisture and dirt will greatly reduce

the life of any air motor. We

recommend the installation of an in-

line filter-regulator-lubricator as close

to the tool as possible.

Pre-Operation

Maintenance

Before the tool is connected to the air

supply, clean the air hose of

accumulated dust and moisture. Before

removing a tool for service or changing

accessories, make sure the air line is

shutoff and drained of air. This will

prevent the tool from operating if the

throttle is accidently engaged.

Operation

Your risk from these exposures

varies, depending on how often

you perform this type of work.

To reduce your exposure to these

chemicals:work in a well ventilated

area, and work with approved safety

equipment, such as dust masks that

are specially designed to filter out

microscopic particles.

For professional use only.

- Lead from lead based paints

- Crystalline silica bricks and

cement and other masonry

products

- And Arsenic and chromium

from chemically-treated rubber

5.

Supply tool with 90 PSI of

clean, dry air. Higher pressure

drastically reduces tool life. Connect

tool to air line using pipe, hose and

fitting sizes shown in Figure 2.

Air Supply and Connection

Hazards.

Air under pressure can cause severe

injury.

Always shut off air supply, drain

hose of air pressure and disconnect

tool from air supply when not in

use, before changing accessories or

when making repairs.

Never direct air at yourself or

anyone else.

Whipping hoses can cause serious

injury. Always check for damaged

or loose hoses and fittings.

Do not use quick disconnect

couplings at tool. See Figure 2

for correct set-up.

Whenever universal twist couplings

are used, lock pins must be

installed.

Lubrication

Use an air line lubricator with Mobll

Almo 525 air tool oil (model 4ZF22),

adjusted to two (2) drops per minute. If

an air line lubricator cannot be used,

add air motor oil to the inlet once a

day.

1.

2.

2

Some dust created by power

sanding, sawing, grinding,

drilling and other construction activities contains

chemicals known to the State of California to cause

cancer and birth defects or other reproductive harm.

Do not exceed maximum

air pressure of 90 PSI

KEYLESS CHUCK DRILL OPERATION

TO INSTALL A DRILL BIT: Hold the ring

and turn the sleeve clockwise until drill

bit is secured tightly (See Figure 3).

bit. Tightening or loosening the drill bit with air

supply attached may cause injury

Disconnect the air line before

removing or installing a drill

bit. Tightening or loosening the drill bit with air

supply attached may cause injury

Disconnect the air line before

removing or installing a drill

Figure 4

TO REMOVE A DRILL BIT: hold the ring

and turn the sleeve counterclockwise

(See Figure4).

CHUCK KEY DRILL OPERATION

Figure 5

TO INSTALL A DRILL BIT: Insert chuck

key into one of the four chuck key holes.

Turn chuck key backwards to unlock

jaws of drill (See Figure 5). Turn chuck

counterclockwise to open jaws and

insert bit. Turn key forward to lock bit

into place (See Figure 6).

Figure 6

Sleeve

Backward

Forward

Turn Chuck Key

Backward To

Unlock Bit

Turn Chuck Key

Forward To Lock

Bit In Place

Sleeve

Ring

Ring

Exhaust

Bit

Bit