ORBITAL

30

Operation

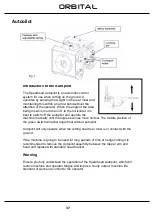

Transport to work position

•

Remove locking pin from slew post.

•

Turn lift ram isolation tap to on position.

•

Ensure rotor/motor switch is off.

•

Engage PTO low revolutions.

•

Lower main lift ram only, until main arm is vertical.

•

Extend dipper arm outward.

•

Flip transport stop over to clear lift frame.

•

Slew arm forward through 90°.

•

Position head till horizontal, just above ground.

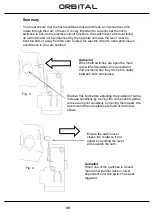

Engaging Head Drive

•

Select 540rpm PTO and run with low engine revs.

•

With flail head in safe position switch

rotor control to ‘ON’.

•

Cold start

- it is important not to run at full speed with cold oil. Run at

low speed for at least 15 minutes to allow oil to warm up.

•

Afterwards slowly increase engine revs to obtain correct PTO speed,

540rpm.

•

Never attempt to start rotor while under load.

Disengage Head Drive

•

Slowly decrease engine revolutions to a fast idle.

•

Move rotor control switc

h to ‘OFF’.

•

Never increase or decrease PTO speed rapidly, this could seriously

damage pumps and motor.

Reversing Head Drive

•

Ensure the rotor has stopped spinning or is not blocked; failure to

ensure this will cause irreparable damage to hydraulic components.

•

Change rotor rotation via the Rotor Reverse switch.

Slew Movement of Head

The slewing ring is more than capable, and care must be taken to ensure it is not

over rotated. The rubber bump stops are fitted as a visual aid and must not be

slewed into. When folding the machine for transport line up the marker between

the rubber cushions to ensure the head linkage folds up in the correct position.