The Servo Trigger has two different servo control modes, selected with

solder jumper 1 (SJ1). They can be used to tailor the response of the board

for different applications.

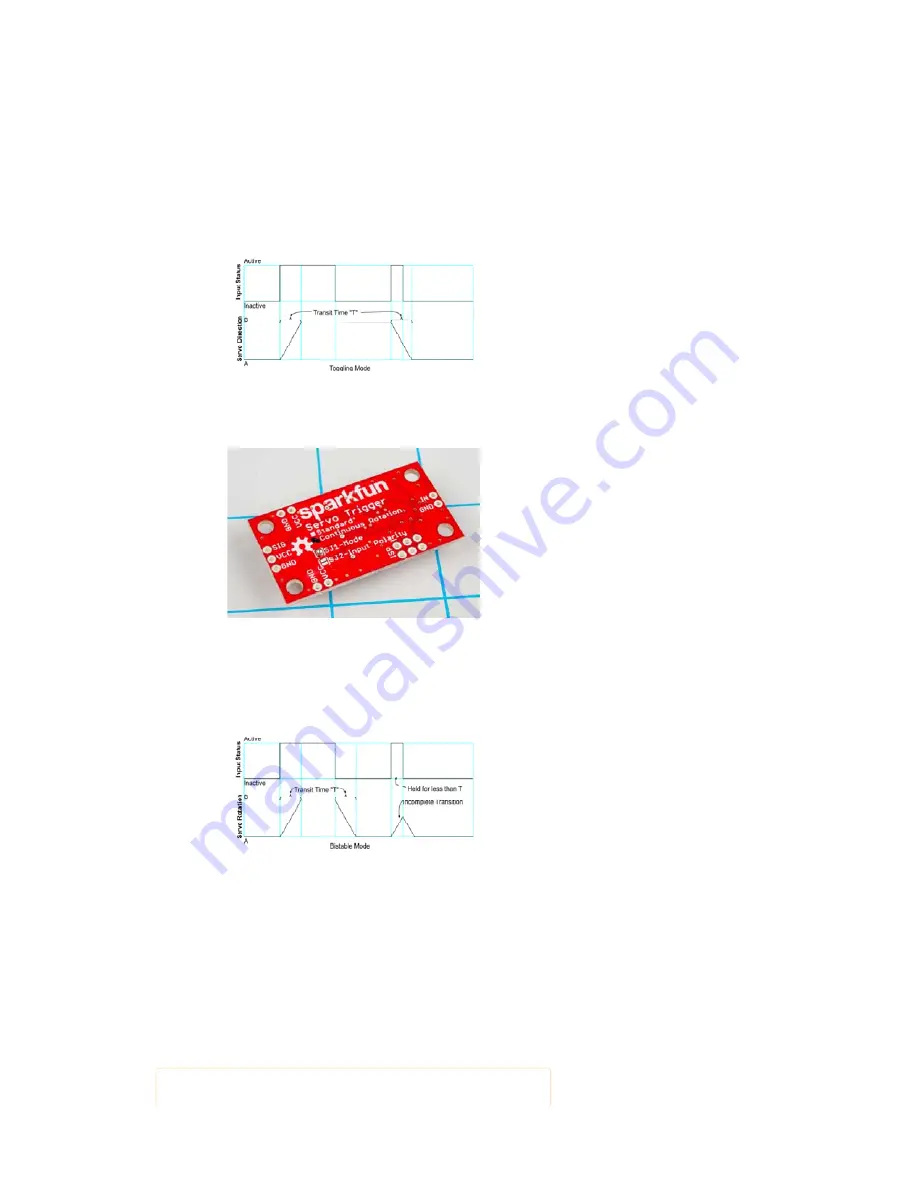

The default mode implements

toggling

control. The trigger initializes

driving the servo as instructed by trimmer

A

. When the switch closes, it

transitions to the speed indicated by

B

. When the switch closes again, it

returns to

A

. The time taken to get between

A

and

B

is selected using

trimmer

T

, which ranges from nearly instantaneous to 10 seconds,

allowwing the motor to gradually slow, stop, and reverse.

Mode Jumper Cleared - Toggling Control

This behavior can be changed by flowing solder between the pads of the

mode jumper.

Closing SJ1 to select bistable mode.

With the solder jumper closed, the mode changes to

bistable

control – the

servo will drive at speed A while the switch is open, and speed B while the

switch is closed. While the switch input stays in a state, the servo drives at

the corresponding speed – it is

stable

in

two

different states.

Mode Jumper Cleared - Bistable Control

Input Polarity

The Servo Trigger input sensitivity can also be changed, using solder

jumper 2 (SJ2).

The default configuration, with no solder applied, configures the Servo

Trigger for use with a normally-open switch, with the internal pull-up resistor

on the microcontroller enabled. This configuration is also suitable for use

with an active-low logic input.

With SJ2 closed, the internal pull-up is disabled, and the input is set as an

active-high logic input.

Page 7 of 13