P

LATINUM

S

ERIES

R

ANGE

PAGE

46

OF 47

OWNER’S MANUAL 1185836 REV 8 (9/14)

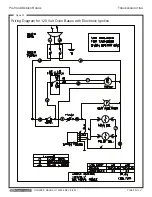

Figure 17

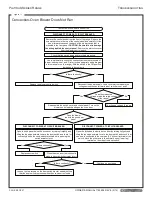

Convection-Oven Blower Does Not Run

DISCONNECT POWER AT CIRCUIT BREAKER.

Convection-oven blower does not run.

Open the kick panel below the oven door by raising it slightly and

tilting the top edge outward. Locate the door switch and check that

one wire is connected to the common (90° bottom) terminal of the

switch. Move the other wire to the normally open (lower leg)

terminal on the side of the door switch.

Check power supply to range.

Does the measured

voltage match the rated voltage

of the range?

Is there continuity?

No

Yes

DISCONNECT POWER AT CIRCUIT BREAKER.

Remove the control knobs from the front of the range. Remove the

screws that secure the top of the control panel and carefully tilt the

panel forward to expose the back of the blower switch that is

mounted in the front panel.

CAUTION: Be careful not to damage

the wiring behind the control panel.

Remove the protective cover

from the blower control switch.

Replace the blower control switch.

Check that the switch wires and terminals are secure.

Reconnect the power supply. Use a voltmeter to measure the

voltage across the center terminals of switch wires 1 and 2.

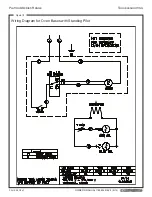

Use a multimeter to check the continuity across the terminals of

blower-switch wires 1 and 3 (refer to the appropriate wiring diagram

in this manual or on the range). With the switch in the ON position,

there should be continuity.

Yes

No

Re-assemble the switch cover and control panel. Turn on the

blower-control switch and open the oven door.

Does the blower

run with the oven door

open?

No

Yes

Open the kick panel below the oven door by raising it slightly and

tilting the top edge outward. Locate the door switch and check for

continuity across the wired switch terminals while pressing the

switch actuator lever.

DISCONNECT POWER AT CIRCUIT BREAKER.

Loosen the two screws on the door switch bracket and adjust it so

that the door switch is pressed when the oven door is closed.

Replace door switch.

Close the oven door (which should

press the door-switch actuator lever).

Is there continuity?

No

Yes

Is there continuity?

No

Yes

Continue on next page.

T

ROUBLESHOOTING