– 21 –

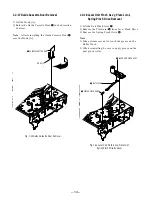

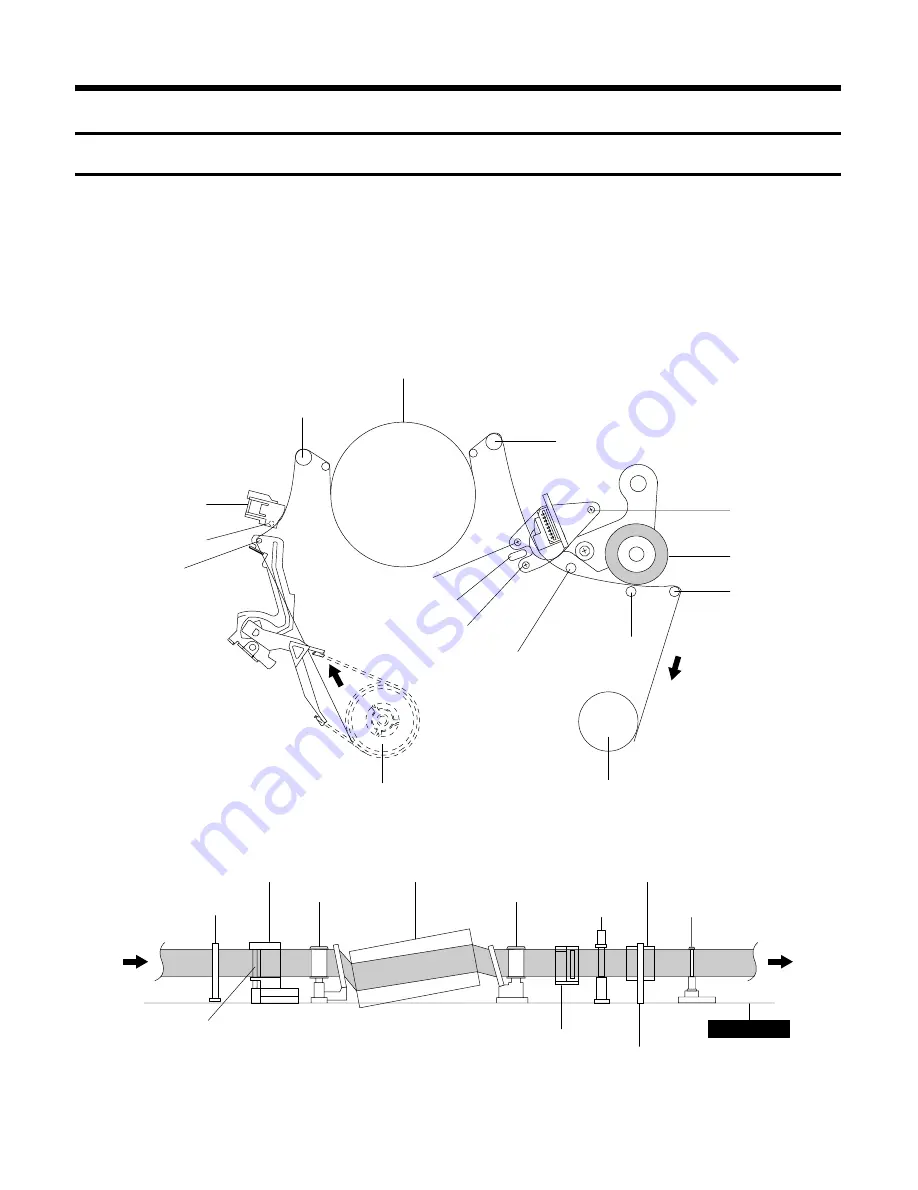

Fig. 2-1 Location of Tape Transport Adjustment

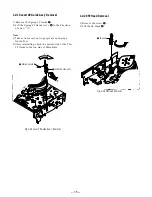

Fig. 2-2 Tape Travel Diagram

CYLINDER ASS'Y

TAKE UP REEL DISK

#8 GUIDE POST

#9 GUIDE POST

SUPPLY REEL DISK

CAPSTAN

PINCH ROLLER

GUIDE ROLLER "T"

GUIDE ROLLER "S"

FULL ERASE HEAD

#3 GUIDE POST

TENSION POST

HEIGHT SCREW

TILT SCREW

X - POSITION

ADJUST SILT

AZIMUTH SCREW

POST TENSION

MAIN BASE

FE HEAD

CYLINDER ASS'Y

PINCH ROLLER

GUIDE ROLLER "S"

GUIDE ROLLER "T"

#8 GUIDE POST #9 GUIDE POST

CAPSTAN SHAFT

ACE HEAD

#3 GUIDE POST

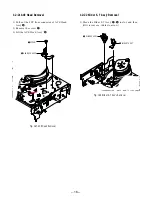

2. Alignment and Adjustment

2-1 Tape Transport System and Adjustment Locations

The tape transport system has been adjusted precisely in the factory. Alignment is not necessary except for the

following :

1) Noise observed on the screen.

2) Tape damage.

3) Parts replacement in the tape transport system.

Lower flange height of tape guide is used as the reference for the transport adjustment.

To maintain the height of the tape guide and prevent damage, do not apply excessive force onto the main base.