4

MEX-R5

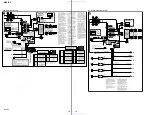

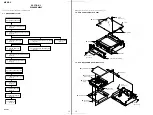

MODEL IDENTIFICATION

Label indication

Signal format

Region

Part No.

Destination

system

code

NTSC

1

2-631-964-01 US, Canadian models

PAL

2

2-631-969-01 AEP, UK models

PAL

5

2-638-206-01 Russian model

PAL

3

2-634-525-01 E: PAL model

NTSC

4

2-634-528-01 E: NTSC model

PAL

6

2-639-072-01 Chinese model

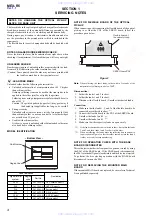

SECTION 1

SERVICING NOTES

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

Never look into the laser diode emission from right above when

checking it for adjustment. It is feared that you will lose your sight.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the lead-

free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

•

Unleaded solder melts at a temperature about 40 ˚C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 ˚C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

•

Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

•

Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

NOTE FOR FLEXIBLE BOARD OF THE OPTICAL

PICK-UP

When connecting or disconnecting the flexible board of the optical

pick-up to or from the CN2 of the SERVO board, follow the

procedure given below.

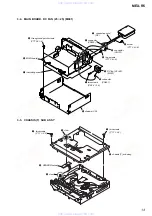

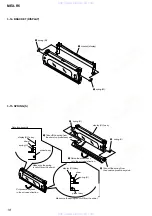

Figure 1

Note:

When soldering the short lands, solder within 5 seconds at the

temperature of soldering iron below 300

°

C.

Disconnection:

1. Solder the lands 3 and 2 to short.

2. Solder the lands 1 and 2 to short.

3. Disconnect the flexible board. (Unsolder the shorted lands)

Connection:

1. Make sure that the lands 1, 2, and 3 of the flexible board to be

connected are soldered to short.

(*1)

2. Connect the flexible board to the CN2 of the SERVO board.

3. Unsolder the lands 1 and 2.

(*2)

4. Unsolder the lands 3 and 2.

(*2)

5. Make sure that the respective lands are open surely.

*1)

If the lands concerned are not soldered to short, first solder the lands

3 and 2, and then lands 1 and 2 to short in this order.

*2)

When unsoldering the lands, move the soldering iron in bottom to

top direction in Figure 1 so that the solder runs away into the land 4

(solder reservoir) for easy unsoldering.

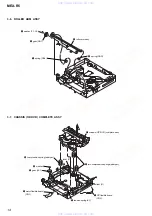

NOTE FOR OPERATION CHECK WITH THE BASE

BOARD DISCONNECTED

This set detects whether the front panel is opened or closed by using

the S961 of the BASE board. If the BASE board is disconnected,

the S961 is turned off (panel closed status) and the disc is not ejected.

To perform the disc ejecting operation with the BASE board

disconnected, turn on the S961.

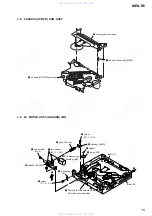

NOTE FOR REPLACING THE MOUNTED MAIN

BOARD

If the mounted MAIN board was replaced, be sure refer to Technical

News published separately.

– Bottom View –

4

2

1

Flexible board of

the optical pick-up

SERVO board CN2

3

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299