DSC-RX10_L2

1-3

– ENGLISH –

1-5. SELF-DIAGNOSIS FUNCTION

1-5-1. Self-diagnosis Function

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the LCD screen what to do.

Details of the self-diagnosis functions are provided in the Instruction

manual.

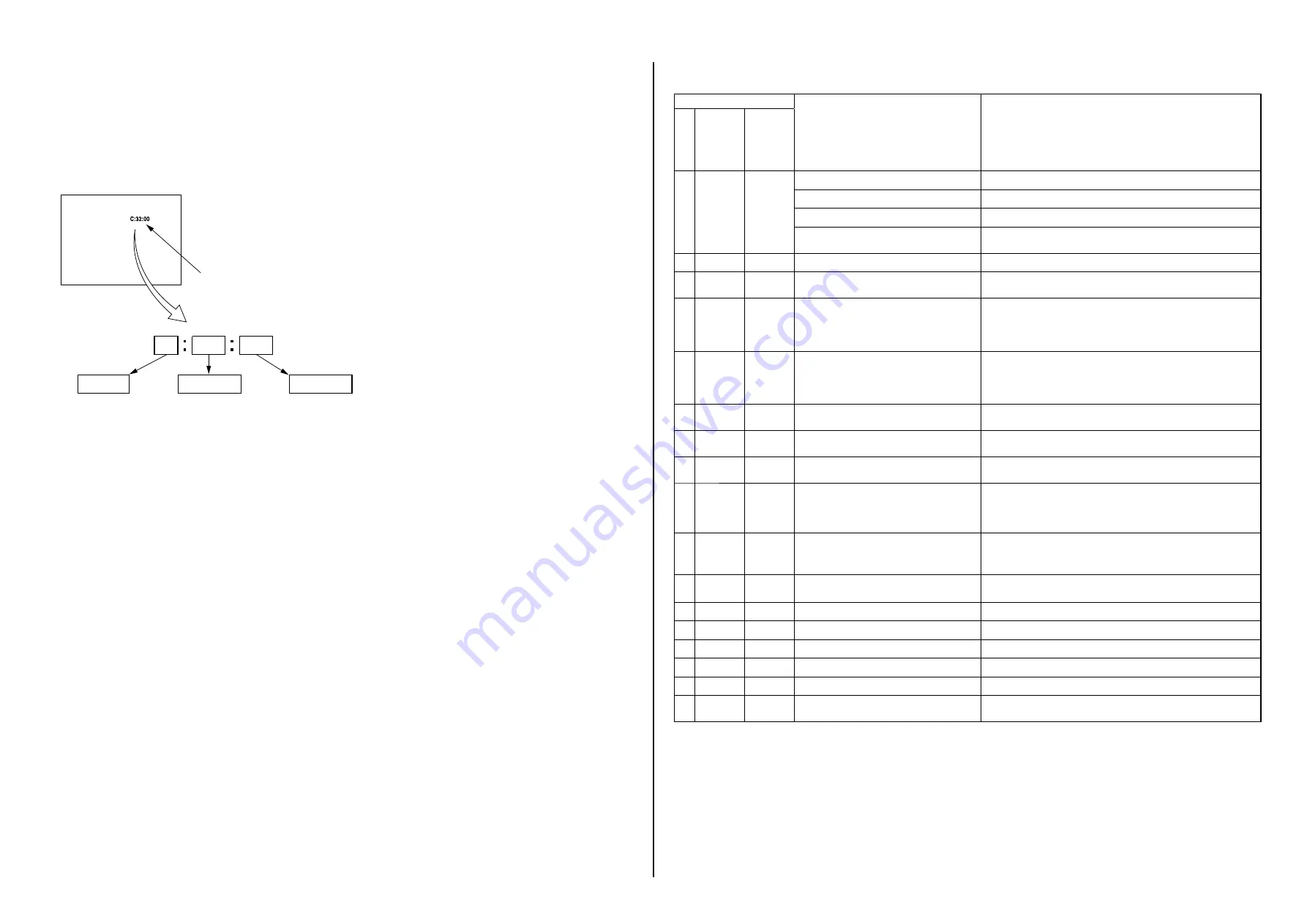

1-5-2. Self-diagnosis Display

When problems occur while the unit is operating, the LCD screen shows

a 4-digit display consisting of an alphabet and numbers, which blinks

at 3.2 Hz. This 5-character display indicates the “repaired by:”, “block”

in which the problem occurred, and “detailed code” of the problem.

0 0

3 2

C

Repaired by:

Refer to “1-5-3. Self-diagnosis Code Tabl e”.

Indicates the appropriate

step to be taken.

E.g.

13 ....Format the “memory card”.

32 ....Turn on power again.

Block

Detailed Code

Blinks at 3.2 Hz

C : Corrected by customer

E : Corrected by service

engineer

LCD screen

1-5-3. Self-diagnosis Code Table

Self-diagnosis Code

Symptom/State

Correction

Repaired by:

Block

Function

Detailed

Code

C

1

3

0

1

Memory card is unformatted.

Format the memory card.

Memory card is broken.

Insert a new memory card.

Memory card type error

Insert a supported memory card.

The camera cannot read or write data on the

memory card.

Turn the power off and on again, or taking out and inserting the

memory card several times.

C

3

2

0

1

Trouble with hardware

Turn the power off and on again.

E

4

1

0

0

Abnormality of wireless LAN module or

host CPU.

Replace the SY-1027 board.

E

6

1

0

0

Difficult to adjust focus

(Cannot initialize focus)

Retry turn the power on by the power switch. If it does not recover,

check the focus MR sensor signal of lens block (pin

2

,

4

of CN3101

on the SY-1027 board). If it is OK, check the focus motor drive IC

(IC3104 on the SY-1027 board).

E

6

1

1

0

Zoom operations fault

(Cannot initialize zoom lens.)

Retry turn the power on by the power switch. Check the zoom reset

sensor signal of lens block (pin

ej

of CN3101 on the SY-1027 board)

when zooming is performed when the zoom button is operated. If it is

OK, check the zoom motor drive IC (IC3104 on the SY-1027 board).

E

6

1

3

0

Reset position detection error on the stepper

iris initializing

Turn power off and turn power on again.

E

6

2

0

2

Abnormality of IC for steadyshot.

Check or replacement of the IC for steadyshot (IC3104 on the SY-

1027 board).

E

6

2

1

0

Lens initializing failure.

Check or replacement of the IC for steadyshot (IC3104 on the SY-

1027 board).

E

6

2

1

1

Lens overheating (PITCH).

Check the HALL element (PITCH) of optical image stabilizer (pin

5

,

7

of CN3101 on the SY-1027 board). If it is OK, check PITCH

angular velocity sensor (SE3100 on the SY-1027 board) peripheral

circuits.

E

6

2

1

2

Lens overheating (YAW).

Check the HALL element (YAW) of optical image stabilizer (pin

9

,

qa

of CN3101 on the SY-1027 board). If it is OK, check YAW angular

velocity sensor (SE3100 on the SY-1027 board) peripheral circuits.

E

6

2

2

0

Abnormality of thermistor.

Check the temp sensor of optical image stabilizer (pin

eg

of CN3101

on the SY-1027 board).

E

9

1

0

1

Abnormality when flash is being charged.

Checking of flash unit or replacement of flash unit. (Note 1)

E

9

2

0

0

Battery / Dry cell distinction defect

Turn power off and turn power on again.

E

9

4

0

0

Internal memory fault

Turn power off and turn power on again.

E

9

5

0

0

GPS hardware error

Turn power off and turn power on again.

E

9

5

0

1

Acceleration sensor hardware error

Turn power off and turn power on again.

E

9

5

0

2

Electronic compass hardware error

(GPS hardware error)

Turn power off and turn power on again.

Note 1:

After repair, be sure to perform “1-6. PROCESS AFTER FIXING FLASH ERROR”.

Note 2:

Functions of codes with * mark are not provided in this unit.

*

*

*