27

KMS

260A

27X40

B0825

T

IOP = 82.5 mA in this case

IOP (mA) = Digital voltmeter reading (mV)/1 (

Ω

)

5. Then “MD LD 7.0 mW $

” will be displayed.

6. Rotate the

l L

knob so that the reading of the laser

power meter becomes 6.9 to 7.1 mW, press the ENTER/YES

button and save it.

Note :

Do not perform the emission with 7.0 mW more than 15

seconds continuously.

7. Then, rotate the

l L

knob and display “MD LDPWR

CHECK”.

8. Press the ENTER/YES button once and display “MD 0.9 mW

***

$

”. Check that the reading of the laser power meter be-

come 0.85 to 0.91 mW. (

***

means the IOP value)

9. Press the ENTER/YES button once more and display “MD 7.0

mW

***

$

”. Check that the reading the laser power meter

and digital volt meter satisfy the specified value.

Note down the digital voltmeter reading value.

Specified Value :

Laser power meter reading : 7.0 ± 0.1 mW

Digital voltmeter reading : Optical pick-up displayed value ± 10%

(Optical pick-up label)

10. Press the MENU/NO button and display “MD LDPWR

CHECK” and stop the laser emission.

(The MENU/NO button is effective at all times to stop the

laser emission.)

11. Rotate the

l L

knob to display “MD Iop Write”.

12. Press the ENTER/YES button. When the display becomes

Ref=@@@.@ (@ is an arbitrary number), press the ENTER/

YES button to display “MD Measu=@@@.@” (@ is an arbi-

trary number).

13. The numbers which can be changed will blink. Input the IOP

value noted down at step 9.

To select the number : Rotate the

l L

knob.

To select the digit : Press the SYNCHRO REC button.

Selection of digit : Press the SYNCHRO REC button.

14. When the ENTER/YES button is pressed, “Complete!” will

be displayed momentarily. The value will be recorded in the

non-volatile memory and the display will become “MD Iop

Write”.

Note 1:

After step 4, each time the ENTER/YES button is pressed,

the display will be switched between “MD 0.7 mW

***

$

”, “MD 6.2 mW

***

$

”, and “MD Wp

***

$

”. Nothing needs to be performed here.

(For details of the method for checking

this value, refer to “5-8. Recording and

Displaying the IOP Information”.)

5-11. TRAVERSE ADJUSTMENT

Connection :

Adjusting Procedure :

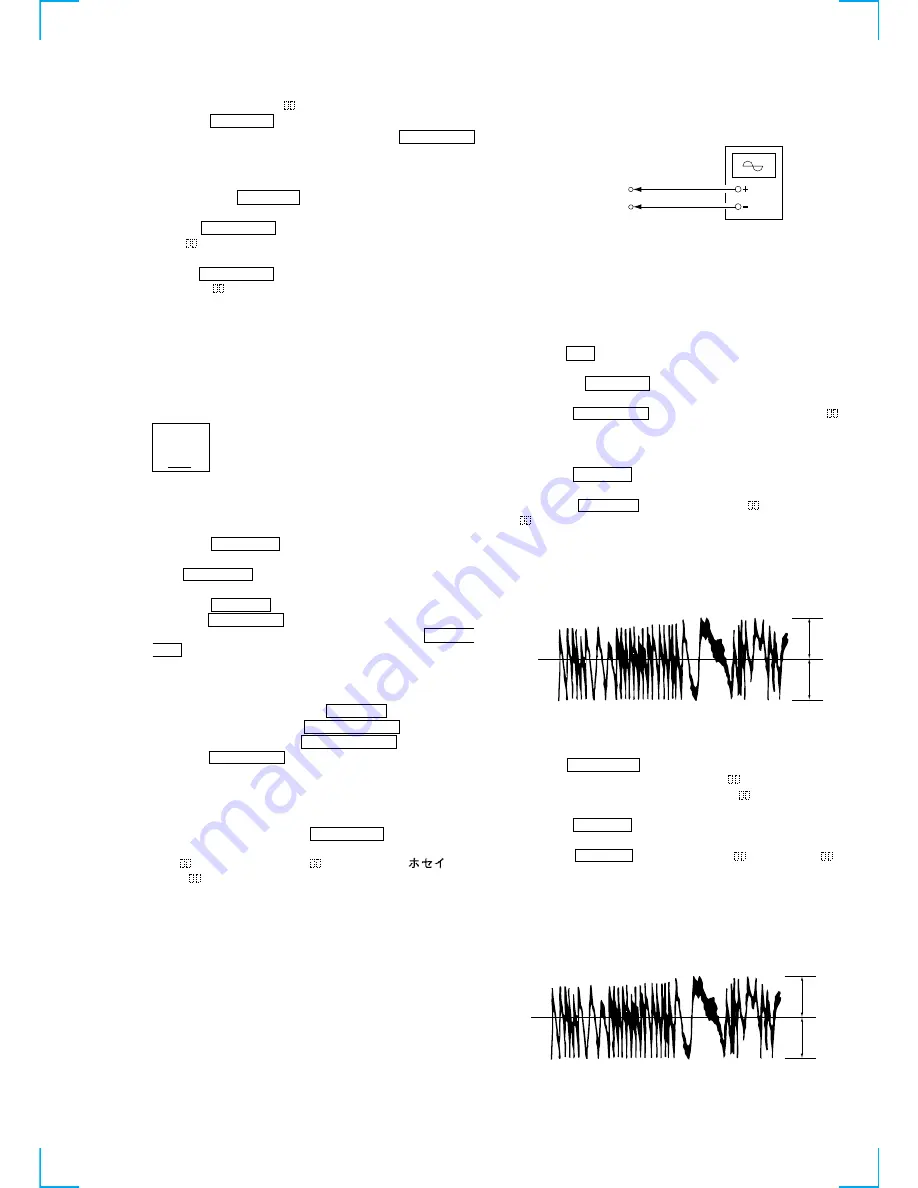

1. Connect an oscilloscope to CN110 pin

3

(TE) and CN110 pin

1

(VC) of the BD board.

2. Load a disc (any available on the market). (Refer to Note 1.)

3. Press the

M

button and move the optical pick-up outside the

pit.

4. Rotate the

l L

knob and display “MD EF MO

ADJUST”.

5. Press the ENTER/YES button and display “MD EFB =

MO-R”.

(Laser power READ power/Focus servo ON/tracking servo OFF/

spindle (S) servo ON)

6. Rotate the

l L

knob so that the waveform of the oscillo-

scope becomes the specified value.

(When the

l L

knob is rotated, the

of “MD EFB=

” changes and the waveform changes.) In this adjustment,

waveform varies at intervals of approx. 2%. Adjust the wave-

form so that the specified value is satisfied as much as possible.

(Read power traverse adjustment)

(Traverse Waveform)

7. Press the ENTER/YES button and save the result of adjustment

to the non-volatile memory (“MD EFB =

SAVE” will be dis-

played for a moment. Then “MD EFB =

MO-W” will be

displayed).

8. Rotate the

l L

knob so that the waveform of the oscillo-

scope becomes the specified value.

(When the

l L

knob is rotated, the

of “MD EFB-

”

changes and the waveform changes.) In this adjustment, wave-

form varies at intervals of approx. 2%. Adjust the waveform so

that the specified value is satisfied as much as possible.

(Write power traverse adjustment)

(Traverse Waveform)

V : 0.5 V/div

H : 10 ms/div

Input : DC mode

Oscilloscope

BD board

CN110 pin

3

(TE)

CN110 pin

1

(VC)

VC

A

B

Specification A = B

VC

A

B

Specification A = B