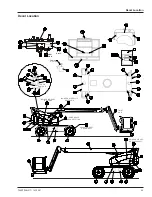

Decal Location

24

T40RT/T46JRT – 1430001

ITEM PART NO.

QTY. DESCRIPTION

1

511090-000 1

DECAL, SNORKEL T40RT

511091-000 1

DECAL, SNORKEL T46JRT

2

0162336E

6

DECAL, DNGR ELECTRICAL

HAZARD – ENGLISH

0162366

6

DECAL, DNGR ELECTRICAL

HAZARD – ENGLISH

0162336F

6

DECAL, DNGR ELECTRICAL

HAZARD – FRENCH

0162366

6

DECAL, DNGR ELECTRICAL

HAZARD – FRENCH

0162336P

6

DECAL, DNGR ELECTRICAL

HAZARD – SPANISH

0162366

6

DECAL, DNGR ELECTRICAL

HAZARD – SPANISH

0162336W

6

DECAL, DNGR ELECTRICAL

HAZARD – SWEDISH

0162366

6

DECAL, DNGR ELECTRICAL

HAZARD – SWEDISH

0162336D

6

DECAL, DNGR ELECTRICAL

HAZARD – DUTCH

0162366

6

DECAL, DNGR ELECTRICAL

HAZARD – DUTCH

0162336G

6

DECAL, DNGR ELECTRICAL

HAZARD – GERMAN

0162366

6

DECAL, DNGR ELECTRICAL

HAZARD – GERMAN

3

509471-000 2

DECAL, SNORKEL T40RT

509470-000 2

DECAL, SNORKEL T46JRT

4

511099-000 2

DECAL, SNORKEL

5

0323897

1

DECAL, DNGR YOU MUST

NOT OPERATE

6

0162329E

2

DECAL, BRIEF OPERATING

INSTRUCTIONS – ENGLISH

0162328E

2

DECAL, ADDITIONAL

OPERATING INSTRUCTIONS

– ENGLISH

0162329F

2

DECAL, BRIEF OPERATING

INSTRUCTIONS – FRENCH

0162328F

2

DECAL, ADDITIONAL

OPERATING INSTRUCTIONS

– FRENCH

0162329P

2

DECAL, BRIEF OPERATING

INSTRUCTIONS – SPANISH

0162328P

2

DECAL, ADDITIONAL

OPERATING INSTRUCTIONS

– SPANISH

0162329W

2

DECAL, BRIEF OPERATING

INSTRUCTIONS – SWEDISH

0162328W

2

DECAL, ADDITIONAL

OPERATING INSTRUCTIONS

– SWEDISH

ITEM PART NO.

QTY. DESCRIPTION

0162329D

2

DECAL, BRIEF OPERATING

INSTRUCTIONS – DUTCH

0162328D

2

DECAL, ADDITIONAL

OPERATING INSTRUCTIONS

– DUTCH

0162329G

2

DECAL, BRIEF OPERATING

INSTRUCTIONS – GERMAN

0162328G

2

DECAL, ADDITIONAL

OPERATING INSTRUCTIONS

– GERMAN

8

1430038

1

PLACARD, LOWER

CONTROL PANEL TOP

9

0070540

3

DECAL, YELLOW ARROW

10

0070541

3

DECAL, BLUE ARROW

11

0075680

1

PLACARD, CAUTION

SERIAL NUMBER

12

0073089

1

BATTERY DISCONNECT

13

106992-000 1

PLACARD, PLATFORM

IDENTIFICATION

14

0071927

1

DECAL, HYDRAULIC OIL

15

7050004

1

RECORD POUCH

16

5623861

1

DOCUMENT HOLDER

17

510280-000 1

DECAL, IPAF EMERG LWR

18

508895-000 1

DECAL, PLAT CAPACITY

19

0073224

1

DECAL, NOTICE MANUAL

RE–ORDER

20

1430330

4

PLACARD, LUG NUT

TORQUE 140 - 170 FT LB

21

0260276

1

PLACARD, AC GENERATOR

22

0260275

1

PLACARD, HYD WARM UP

23

0072531

1

DECAL, DNGR ELECTRICAL

HAZARD

24

0161819E

1

DECAL, EMRG LWR UPPER

25

1430386

1

DECAL, EMRG LWR LOWER

26

0073043

1

DECAL, OPERATING

MANUAL ENCLOSED

27

0073139

1

TAG, CRANKCASE OIL

28

0074311

5

DECAL, DNGR CYLINDER

FAILURE

– ONE PER CYLINDER

30

0190989E

1

DECAL, DNGR DO NOT

REACH – ENGLISH

31

0172451

1

DECAL, ATTACH FALL RSTR

32

0073492

1

DECAL, ROTATE WHILE

GREASING

0073492F

1

DECAL, ROTATE WHILE

GREASING – FRENCH

0073492P

1

DECAL, ROTATE WHILE

GREASING – SPANISH

0073492W

1

DECAL, ROTATE WHILE

GREASING – SWEDISH