Snap-on • 9

Brake Lathes

Reconditioning Disc

Brake Rotors

1.

Inspect the rotor carefully for scoring, rust ridges

(at the inner and outer circumference of the rotor), and

hard spots. Any excessive wear or deformity should

be noted and, if not within acceptable limits, the rotor

should be replaced.

2.

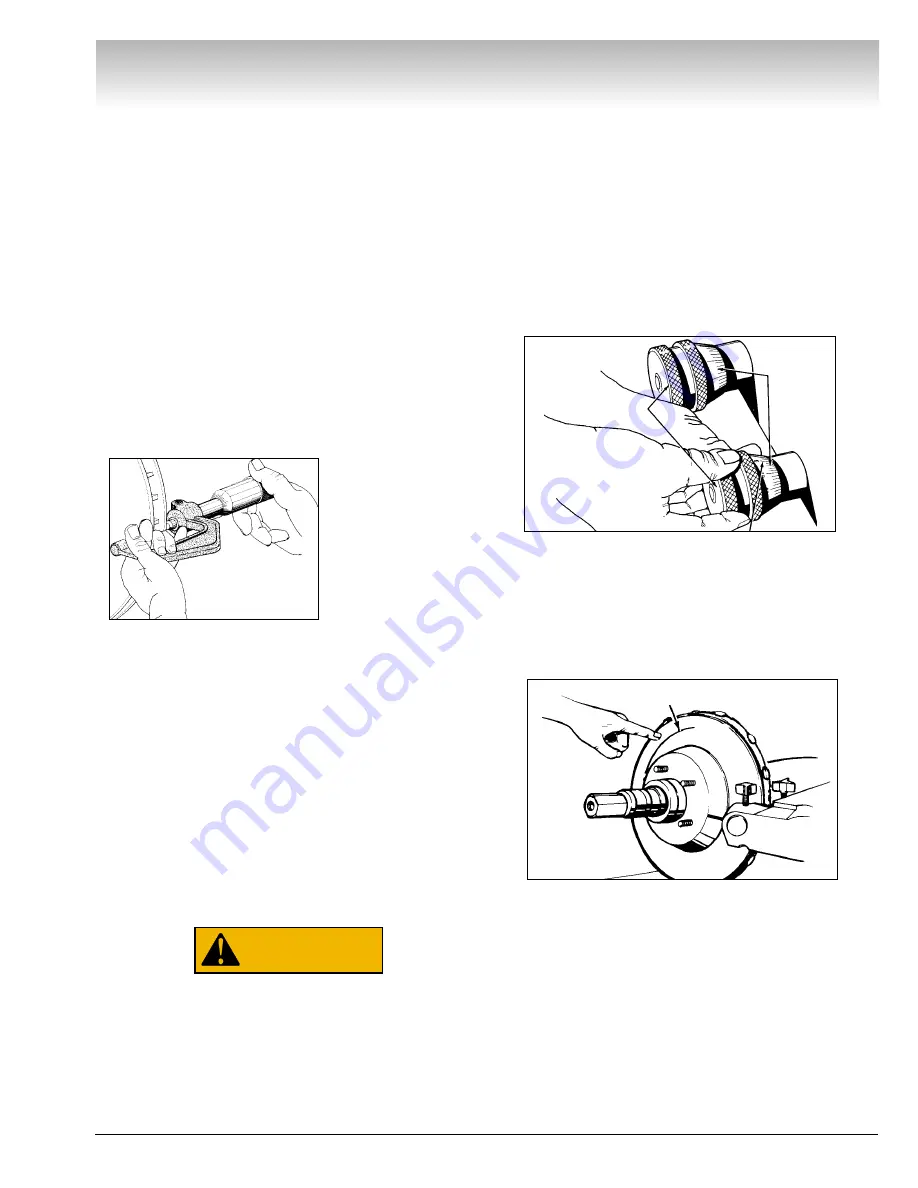

Use a micrometer to check the thickness of the

rotor (figure 5) at no less than 3 points around the cir-

cumference about 1" (2.54 mm) in from the outer

diameter.

If the rotor thickness varies between readings, it

should be reconditioned. However, if the thickness is

less than the minimum established by the manufac-

turer, or if it will be less after reconditioning, the rotor

should be replaced.

Note:

Most often the DISCARD thickness dimension

is cast or stamped

into the rotor, not the

minimum machine-to

thickness.

Figure 5

Set Up and Reconditioning Rotors

1.

Install a silencer band on the mounted rotor.

Stretch the band around the rotor and hook the metal

loop over a lead weight.

2.

Center the twin cutter to the rotor. Loosen the

stud nut and adjust the twin cutter so that the rotor is

centered between the tool bits. Tighten the stud nut

firmly.

3.

Install the safety shield as shown. Review the

cautions and dangers section and the general safety

information at the beginning of this manual. The safety

shield is easily screwed onto the twin cutter in the

threaded mounting hole provided.

Always wear safety glasses or a face shield.

Cutting or grinding on an exposed surface

such as a rotor will produce flying chips

and debris.

4.

Turn the rotor slide handwheel clockwise to posi-

tion the rotor slide about 1/2" away from the

rotor/silencer band (vented rotors), or 1/2" away from

the edge of the rotor (non-vented rotors).

5.

Make sure that the tool bits clear the rotor sur-

faces and the silencer band. Give the rotor a full turn

by hand and watch for clearance all the way around.

6.

Turn the lathe ON.

7.

Turn each tool bit control (the outer knurled

knobs, clockwise until the tool bits just contact the

rotor surfaces.

Figure 6

8.

When the tool bits make contact, rotate each of

the inner depth-of-cut collars to zero and back the tool

bits away from the rotor.

From this point on, all tool adjustments will be made

with the tool bit controls. Then inner depth-of-cut col-

lars will be the reference and should not be moved.

Figure 7

9.

Turn the rotor slide handwheel until the tool bits

are at mid-point of the rotor face.

10.

Turn the left-hand tool bit control until the tool

bit contacts the rotor surface and makes a scratch cut.

After the cut is made, back the tool bits off and turn

the lathe OFF.

The scratch will usually appear as an incomplete cir-

cle. This is caused by runout or wobble due to rotor

condition, or by the way the rotor is mounted on the

arbor.

WARNING

Inner depth-

of-cut collars

Tool bit controls

Hold knob with one

hand – turn collar

Each increment =

0.002” english,

0.05 mm metric

First scratch cut

Micrometer