6

Service

MAINTENANCE

WHEEL MOUNTING PROCEDURE

1. Turn machine off and remove key.

2. Block one of the other wheels.

3. Loosen nuts slightly on wheel to be removed.

4. Jack up machine being careful not to damage underside of machine.

5. Remove nuts. Remove wheel.

5. Place new wheel on hub lining up bolt holes.

6. Torque nuts to 64-74 ft/lb (87-100 Nm) using a cross pattern. Re-torque after first 10 hours and every 200

hours thereafter.

7. Lower machine to ground and remove blocks and jack.

BATTERY

Batteries normally produce explosive gases which can cause personal injury. Do not allow flames, sparks or any

ignited object to come near the battery. When charging or working near battery, always shield your eyes and

always provide proper ventilation.

Battery cable should be disconnected before using "Fast Charge".

Charge battery at 15 amps for 10 minutes or 7 amps for 30 minutes. Do not exceed the recommended charging

rate. If electrolyte starts boiling over, decrease charging.

Always remove grounded (-) battery clamp first and replace it last. Avoid hazards by:

1. Filling batteries in well-ventilated areas.

2. Wear eye protection and rubber gloves.

3. Avoid breathing fumes when electrolyte is added.

4. Avoid spilling or dripping electrolyte.

Battery Electrolyte is an acidic solution and should be handled with care. If electrolyte is

splashed on any part of your body, flush all contact areas immediately with liberal amounts

of water. Get medical attention immediately.

JUMP STARTING

Use of booster battery and jumper cables. Particular care should be used when connecting a

booster battery. Use proper polarity in order to prevent sparks.

To jump start (negative grounded battery):

1. Shield eyes.

2. Connect ends of one cable to positive (+) terminals of each battery, first (A) then (B).

3. Connect one end of other cable to negative (-) terminal of "good" battery (C).

4. Connect other end of cable (D) to engine block on

unit being started (NOT to negative (-) terminal of

battery)

To prevent damage to other electrical components on

unit being started, make certain that engine is at idle

speed before disconnecting jumper cables.

Содержание 14270

Страница 16: ...14 Diagrams HYDRAULICDRAWING ...

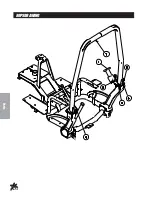

Страница 18: ...16 Parts MAINFRAMEDRAWING ...

Страница 20: ...18 Parts ROPSDRAWING ...

Страница 22: ...20 Parts FRONTFORKDRAWING ...

Страница 24: ...22 Parts LINKAGEDRAWING ...

Страница 26: ...24 Parts LINKAGEDRAWING ...

Страница 28: ...26 Parts FUELTANKDRAWING ...

Страница 30: ...28 Parts OILTANKDRAWING ...

Страница 32: ...30 Parts ENGINEDRAWING ...

Страница 34: ...32 Parts ENGINEDRAWING ...

Страница 36: ...34 Parts Torque To 120 ft lbs 156Nm REARAXLEDRAWING ...

Страница 38: ...36 Parts RAKELIFTDRAWING ...

Страница 40: ...38 Parts 13 729 2 BANKHYDRAULICVALVEDRAWING ...

Страница 42: ...40 Parts 43 116FRONTWHEELMOTORDRAWING ...

Страница 44: ...42 Parts 43 117REARWHEELMOTORDRAWING ...

Страница 46: ...44 Parts 42 797 VARIABLEPUMPDRAWING ...