2. Transportation and installation

2 - 6

2.3 Reinstallation of the product

Caution

- Only people who have sufficient knowledge and experience about the product and its

accessories are allowed to reinstall the product in a different location. Also, be sure to

follow the instructions below.

When moving the product to a different location or reinstalling it after it has been used (including trial run),

follow the whole procedure in Chapter 2 beforehand.

- Disconnection of power supply cable

Be sure to cut the facility power supply before disconnecting the power supply cable.

Removal of pneumatic piping

Clean off any sealant debris after the piping is removed. If any sealant debris gets into the product during

reinstallation, it may lead to cooling failure or other product failures.

Residual compressed air pressure release procedure

1. Even while the dryer is removed, only when compressed air is needed, open the bypass piping valve.

2. Close the compressed air inlet and outlet valve.

3. Unscrew the front panel fixing screw (in 2 points) and remove the front panel with upholding it a little.

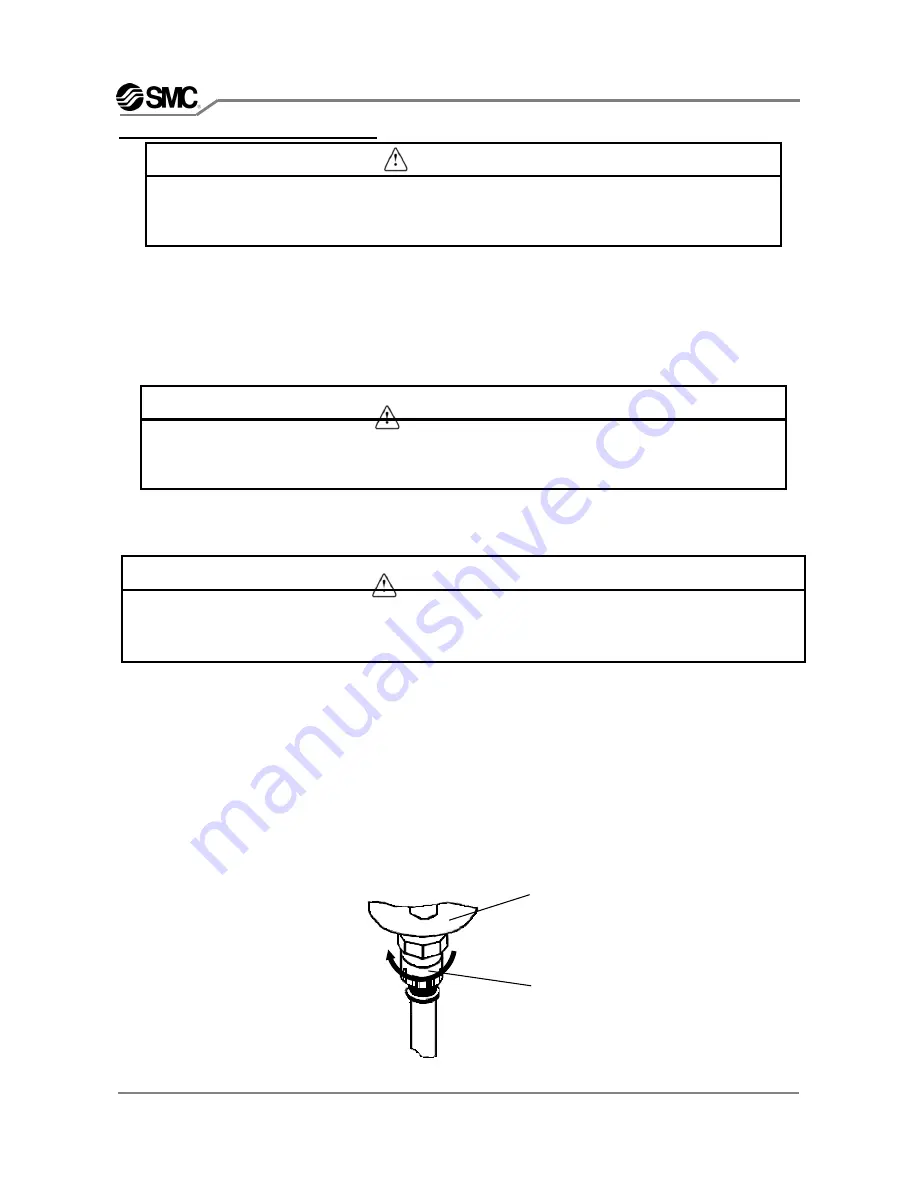

4. Open the residual pressure release cock of auto drain tube, and release compressed air pressure left

inside of the product. Refer to the figure at below.

Warning

- Only people who have sufficient knowledge and experience are allowed to perform wiring.

- Before wiring, be sure to shut off the power supply. Never perform wiring work while the

product is energized.

Warning

- Only people who have sufficient knowledge and experience are allowed to perform piping work.

- Before removing piping, be sure to shut off the air supply and the product.

- Do not remove piping with any air pressure remaining internally.

Case Assembly

The remainder depressure cock.

It opens when turning in the direction

of the arrow of figure.