Warning

Grounding should never be connected to a water line,

gas line or lightning rod.

Caution

1. Power supply and communication cables should be

prepared by user.

2. Provide a stable power supply which is not affected

by surge or distortion.

If the voltage increase ratio (dV/dt) at the zero cross should

exceed 40 V/200

m

sec., it may result in malfunction.

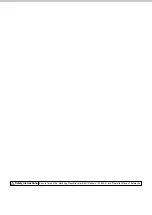

3. This product is installed with a breaker with the

following operating characteristics.

For the user’s equipment (inlet side), use a breaker whose

operating time is equal to or longer than the breaker of this

product. If a breaker with shorter operating time is connected,

the user’s equipment could be cut off due to the inrush current

of the motor of this product.

dV

dV

dt

dt

= Voltage increase ratio

Time

Voltage

4 h

2 h

1 h

30 min

20 min

14 min

10 min

6 min

4 min

2 min

1 min

30 s

20 s

10 s

5 s

2 s

1 s

0.5 s

0.2 s

0.1 s

0.05 s

0.02 s

0.01 s

100

135

200

300

400 500 600 700

1000

1500 2000

3000 4000

Current (% for chiller main breaker volume)

Operating time

Min.

Max.

Electrical Wiring

Be sure to read this before handling the products. For safety instructions and tempera-

ture control equipment precautions, refer to the “Handling Precautions for SMC Prod-

ucts” and the “Operation Manual” on the SMC website: https://www.smcworld.com

HRS200

Series

Specific Product Precautions 4

Circulating Fluid

Caution

1. Avoid oil or other foreign matter entering the

circulating fluid.

2. When water is used as a circulating fluid, use tap

water that conforms to the appropriate water quality

standards.

Use tap water that conforms to the standards shown below (includ-

ing water used for dilution of ethylene glycol aqueous solution).

Tap Water (as Circulating Fluid) Quality Standards

The Japan Refrigeration and Air Conditioning Industry Association

JRA GL-02-1994 “Cooling water system – Circulation type – Make-up water”

Item

Unit

Standard value

Influence

Corrosion Scale

generation

Standard item

pH (at 25

°

C)

—

6.0 to 8.0

v

v

Electric conductivity (25

°

C) [

m

S/cm]

100

*

1

to 300

*

1

v

v

Chloride ion (Cl

–

)

[mg/L]

50 or less

v

Sulfuric acid ion (SO

4

2–

)

[mg/L]

50 or less

v

Acid consumption amount (at pH4.8)

[mg/L]

50 or less

v

Total hardness

[mg/L]

70 or less

v

Calcium hardness (CaCO

3

) [mg/L]

50 or less

v

Ionic state silica (SiO

2

)

[mg/L]

30 or less

v

Ref

erence item

Iron (Fe)

[mg/L]

0.3 or less

v

v

Copper (Cu)

[mg/L]

0.1 or less

v

Sulfide ion (S

2

–

)

[mg/L] Should not be detected.

v

Ammonium ion (NH

4

+

)

[mg/L]

0.1 or less

v

Residual chlorine (Cl)

[mg/L]

0.3 or less

v

Free carbon (CO

2

)

[mg/L]

4.0 or less

v

*

1 In the case of [M

Ω

·cm], it will be 0.003 to 0.01.

v

: Factors that have an effect on corrosion or scale generation.

Even if the water quality standards are met, complete prevention of corrosion

is not guaranteed.

3. Use an ethylene glycol aqueous solution that does

not contain additives such as preservatives.

4. Refer to "Operation at low ambient temperature or low

circulating fluid temperature" (page 14) for the con-

centration of the ethylene glycol aqueous solution.

5. When deionized water is used, the electric conductivity

should be 1

m

S/cm or higher (Electric resistivity: 1

M

Ω

·cm or lower).

Operation

Warning

1. Confirmation before operation

1) The fluid level of a tank should be within the specified range of “HIGH” and “LOW.”

When exceeding the specified level, the circulating fluid will overflow.

2) Remove the air.

Conduct a trial operation, looking at the fluid level.

Since the fluid level will go down when the air is removed

from the user’s piping system, supply water once again

when the fluid level is reduced. When there is no reduction

in the fluid level, the job of removing the air is completed.

Pump can be operated independently.

2. Confirmation during operation

Check the circulating fluid temperature.

The operating temperature range of the circulating fluid is be-

tween 5 and 35

°

C.

When the amount of heat generated from the user’s equipment is

greater than the product’s capability, the circulating fluid tempera-

ture may exceed this range. Use caution regarding this matter.

3. Emergency stop method

When an abnormality is confirmed, stop the machine immedi-

ately. After the machine has stopped, make sure to turn off the

breaker of the user’s equipment (on the upstream side).

16