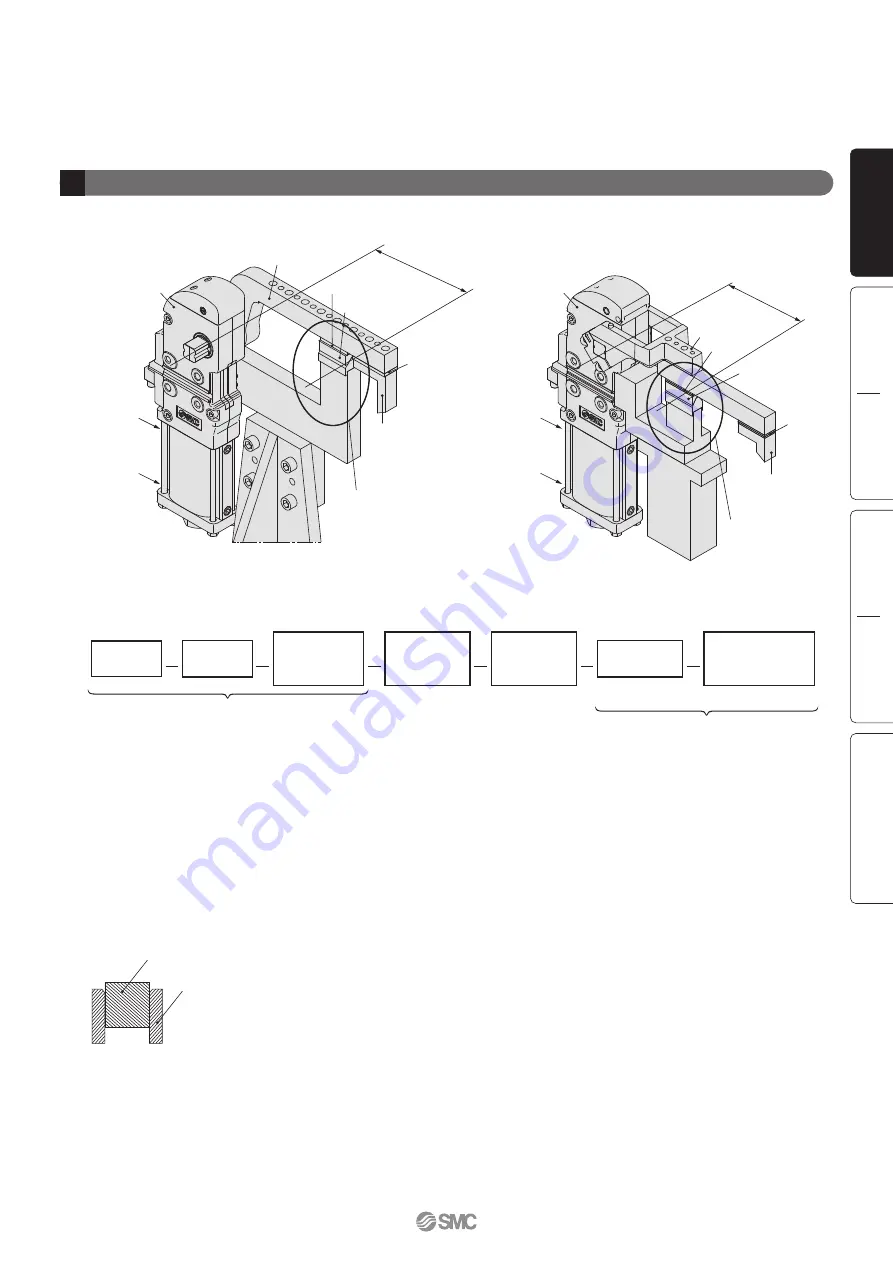

Cylinder

Arm length

L

Shim

w

Clamping

cylinder port

Unclamping

cylinder port

Hard stop section A

Upper hard stop

Clamping

block

Arm length

L

Shim

w

Clamping

cylinder port

Unclamping

cylinder port

Cylinder

Hard stop section A

Upper hard stop

Clamping

block

Shim

q

Clamp arm

(Distance to a hard stop)

(Distance to a hard stop)

Clamp arm

Shim

q

When using a hard stop

When using the side guide

Clamp arm

Side guide

2

Power clamp cylinder mounting

Series

CKZ3N

Series

CKZ3T

Precaution

When using the side guide to the clamp arm to prevent lateral motion, make sure not to apply a lateral load or galling to the clamp

arm.

Procedure

A) Supply air at clamp side without installation of upper hard stop, and operate the clamp arm to the end of clamp.

B) Under the above conditions, adjust shim

q

so that the space between the upper hard stop and the lower hard stop is about 0

mm. Theoretically there is no clamping force to the lower hard stop under this condition.

C) In order to generate clamping force from the state described in step B, insert additional shim. The thickness of the shim differs

depending on the arm length and pressure, so please refer to the graph on front matter 3 as a guide. About 10% error may occur

due to the difference in tolerance of the power clamp cylinder body.

D) Under the state described in step C, adjust shim

w

so there is contact between the clamping block and the workpiece.

Mounting process

Air supply

Hard stop

set

A

Operate to the

end of clamp

Shim adjustment

B

Install the

upper hard

stop

Shim adjustment

Shim adjustment

C

Upper hard

stop contact

adjustment

Workpiece

setting

D

Block contact

adjustment

(clamp side)

Model Selection

CKZ3N

North American Type

Made to Order

European Type

CKZ3T

Front matter 4

Series

CKZ3

Model Selection