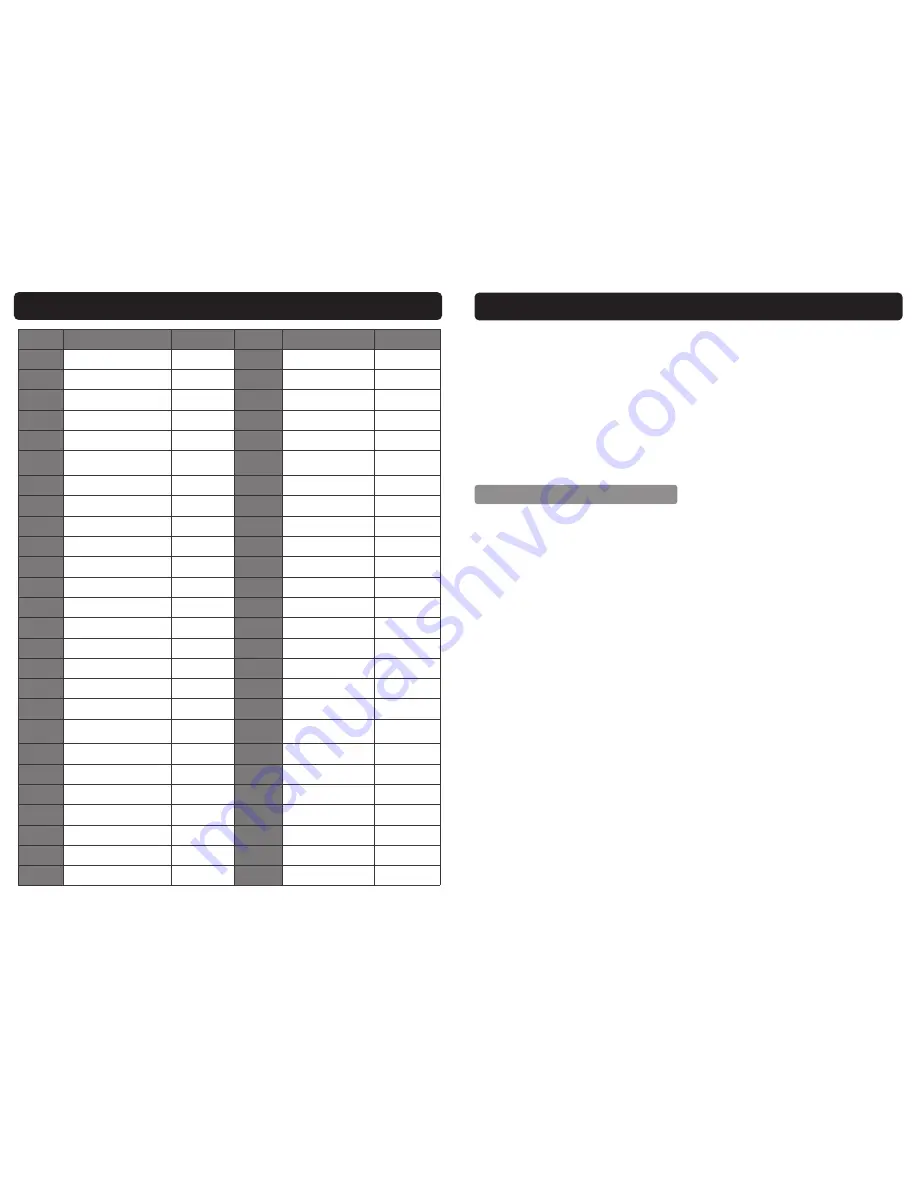

28

Ref. No.

Description

Sip Part No.

Ref. No.

Description

Sip Part No.

1.

Support for wire feeder

WE02-00308

27.

Output load small PCB WE02-00334

2.

Top cover

WE02-00309

28.

Output busbar

WE02-00335

3.

Power transformer

WE02-00310

29.

Front panel

WE02-00336

4.

power filter

WE02-00311

30.

Plastic frame surround WE02-00337

5.

Main PCB

WE02-00312

31.

Dinse socket

WE02-00338

6.

Mounting plate

WE02-00313

32.

Wire feed Control

socket-6 Pin

WE02-00339

7.

3 Phase rectifier bridge

WE02-00314

33.

Potentiometer knob

WE02-00340

8.

Gas bottle retaining chain WE02-00315

34.

Handle

WE02-00341

9.

Mains power cable

WE02-00316

35.

Control panel

WE02-00342

10.

Cable gland

WE02-00317

36.

Output reactor / choke WE02-00343

11.

back pane

WE02-00318

37.

Inductance Filter

WE02-00344

12.

Leakage protection switch WE02-00319

38.

left side panel

WE02-00345

13.

Switch bracket

WE02-00320

39.

Main transformer

WE02-00346

14.

Fan

WE02-00321

40.

Heatshield

WE02-00347

15.

Perspex Insulating Screen WE02-00322

41.

Heatshield insulator

WE02-00348

16.

right-side plate

WE02-00323

42.

IGBT

WE02-00349

17.

Heatsink

WE02-00324

43.

IGBT busbar

WE02-00350

18.

Fast Recovery Diode

WE02-00325

44.

Common inductor

WE02-00351

19.

Output rectifier board

WE02-00326

45.

Wire feed PCB

WE02-00352

20.

Rear wheel - single

WE02-00327

46.

PWM PCB

WE02-00353

21.

Bottle carrier

WE02-00328

47.

Capacitor fixing panel WE02-00354

22.

Heatsink bracket

WE02-00329

48.

Capacitor filter

WE02-00355

23.

Bottom

WE02-00330

24.

Bottom baffle plate

WE02-00331

25.

Swivel Castor wheel

WE02-00332

26.

Heatsink Insulator

WE02-00333

PARTS LIST - WELDING INVERTER 05776

9

SAFETY INSTRUCTIONS….cont

Ventilation must be adequate to remove the smoke and fumes during welding

(see the relevant safety standard for acceptable levels).

Toxic gases may be given off when welding, especially if zinc or cadmium coated

materials are involved, welding should be carried out in a well ventilated area

and the operator should always be alert to fume build-up.

Areas with little or no ventilation should always use a fume extractor.

Vapours of chlorinated solvents can form the toxic gas phosgene when exposed

to U.V radiation from an electric arc. All solvents, degreasers and potential

sources of these vapours must be removed from the arc area.

Severe discomfort, illness or death can result from fumes, vapours, heat, oxygen

enrichment or depletion that welding (or cutting) may produce. This will be pre-

vented by adequate ventilation or using a fume extractor.

NEVER

ventilate with

oxygen.

Lead, cadmium, zinc, mercury, beryllium bearing and similar materials when

welded may produce harmful concentrations of toxic fumes. Adequate ventila-

tion must be provided for every person in the area. The operator should also

wear an air supplied respirator, for beryllium both must be used.

Metals coated with or containing materials that emit toxic fumes should not be

heated unless coating is removed from the work surface. The area should be well

ventilated or the operator should wear an air supplied respirator.

Work in a confined space only while it is being ventilated and if necessary whilst

wearing an air supplied respirator.

Gas leaks in a confined space should be avoided, leaking gas in large quantities

can change oxygen concentration dangerously.

DO NOT

bring gas cylinders into

a confined space.

VENTILATION

Avoid oily or greasy clothing, a spark may ignite them.

Hot metal such as electrode stubs and work-pieces should never be handled

without gloves.

First aid facilities and a qualified first aid person should be available for each shift

unless medical facilities are close by for immediate treatment of flash burns to

the eyes and skin.

Flammable hair products should not be used by persons intending to weld.

Warn bystanders not to watch the arc and not to expose themselves to the weld-

ing arc rays or to hot metal.