12

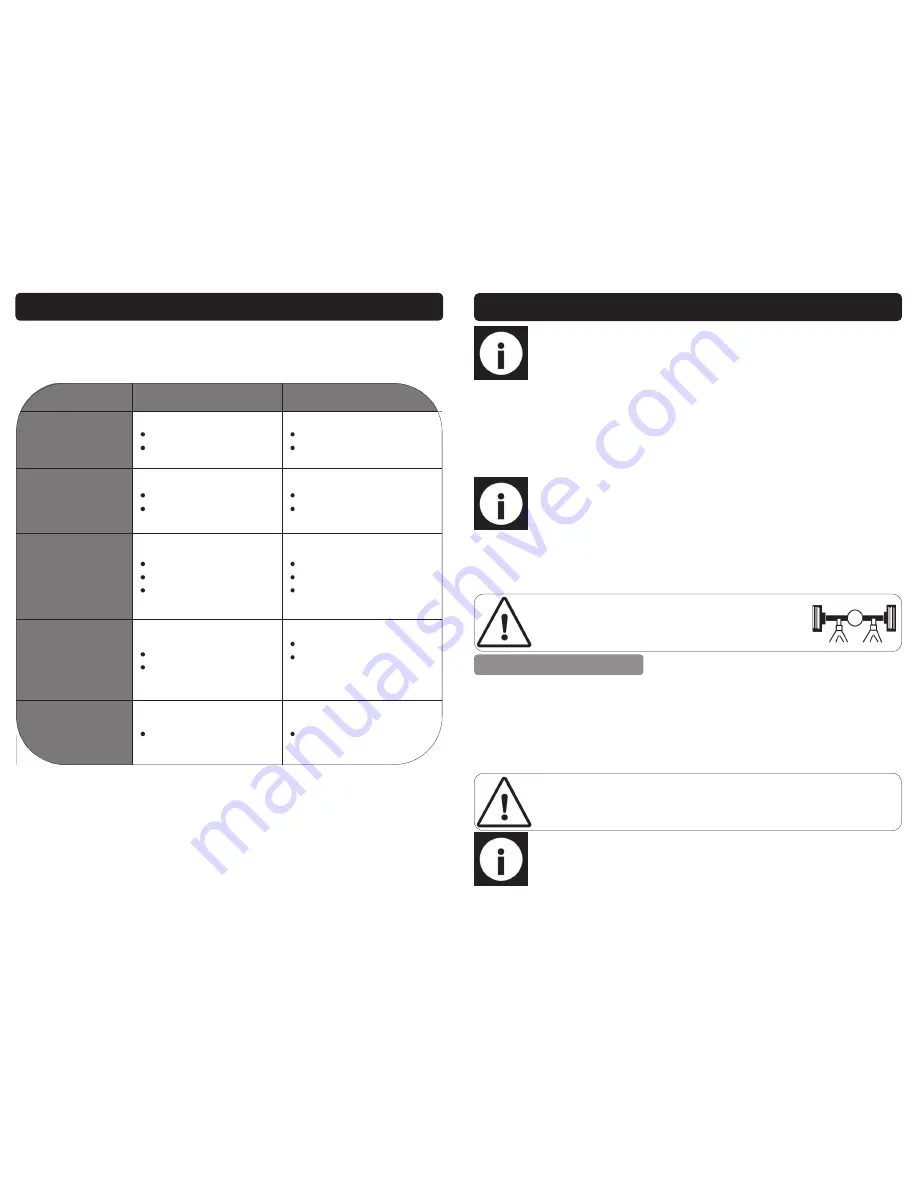

TROUBLESHOOTING

Symptom

Possible Causes

Corrective Action

Jack will not lift load.

Release valve not tightly closed.

Load is too heavy.

Ensure release valve tightly closed.

Consider higher capacity jack.

Jack will lift, but not

maintain pressure.

Release valve not tightly closed.

Hydraulic unit malfunction.

Ensure release valve tightly closed.

Discontinue use, contact supplier.

Jack will not lower after

unloading.

Reservoir overfilled.

Linkages binding.

Low oil level.

Drain oil to proper level.

Clean and lubricate moving parts.

Ensure proper oil level.

Low oil level.

Air trapped in system.

Ensure proper oil level.

With the ram fully retracted, remove

the oil fill bung to let pressurized air

escape. Reinstall the oil fill bung.

Poor lift performance.

Will not lift to full extension.

Low oil level.

Ensure proper oil level.

9

OPERATING INSTRUCTIONS….cont

LOWERING THE JACK

1. Push the handle into the handle base, use the bolt, washer and nut in the handle

base to secure.

2. Close the release valve by turning the release knob clockwise until firm resistance is

felt.

3. Locate the lifting point, centre the jack saddle under the lifting point.

4. Ensure the handle lock is released and the handle can move freely.

5. Pump the handle or foot pedal to contact the lifting point; continue to pump the

handle until the load reaches the desired height.

6. Transfer the load immediately to appropriately rated jack stands.

1. Raise the load high enough to allow it to clear the jack stands.

2. Carefully remove the jack stands.

3. Slowly turn the release knob anti-clockwise to open the release valve - Never turn

the release knob more than a ¼ of a turn at a time.

4. Allow the load to slowly lower to its original position.

5. Remove the jack from under the vehicle.

Caution:

Take care when lowering the jack that nothing can get trapped

in the moving parts of the jack, or under the load.

Note:

Follow the vehicle manufacturer’s recommended guidelines for lift-

ing. Engage the emergency brake and chock each un-lifted wheel in both

directions to prevent inadvertent vehicle movement.

Note:

Refer to the vehicle manufacturer owner’s manual to locate ap-

proved lifting points on the vehicle.

Note:

After removing the jack from under the vehicle, fully lower the saddle

to reduce ram exposure to contamination.

NEVER

use the hydraulic jack as a stand alone device!

ALWAYS

transfer the lifted load

IMMEDIATELY

to a pair of appropriately rated

jack stands. Use one pair of jack stands per vehicle. Do not exceed

the rated capacity.